- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction to Blister Packing Machines: Key Solutions for Efficient Packaging

Key Features and Performance of Blister Machines

For high-efficiency production, the automatic blister packing machine is widely used. This machine automates the entire packaging process, from blister forming to sealing, enhancing productivity while reducing labor costs. As for the automatic blister packing machine price, it can vary depending on the machine's automation level and production capacity.

Blister Equipment for Various Industries

Price Considerations

Conclusion

Suitable for:

Pharmaceutical industry: tablets, capsules, syringes, ampoule, vials, antipyretic stickers, test paper, medical instruments and other packaging.

Food industry: candy, chocolate, cheese, jam, lollipop, jelly, yogurt, surprise eggs and other packaging.

Cosmetics industry: mask, eye paste, hair film, mouthwash and other packaging.

Daily use industry: condom, cigarette holder, razor, toothbrush, card and other packaging.

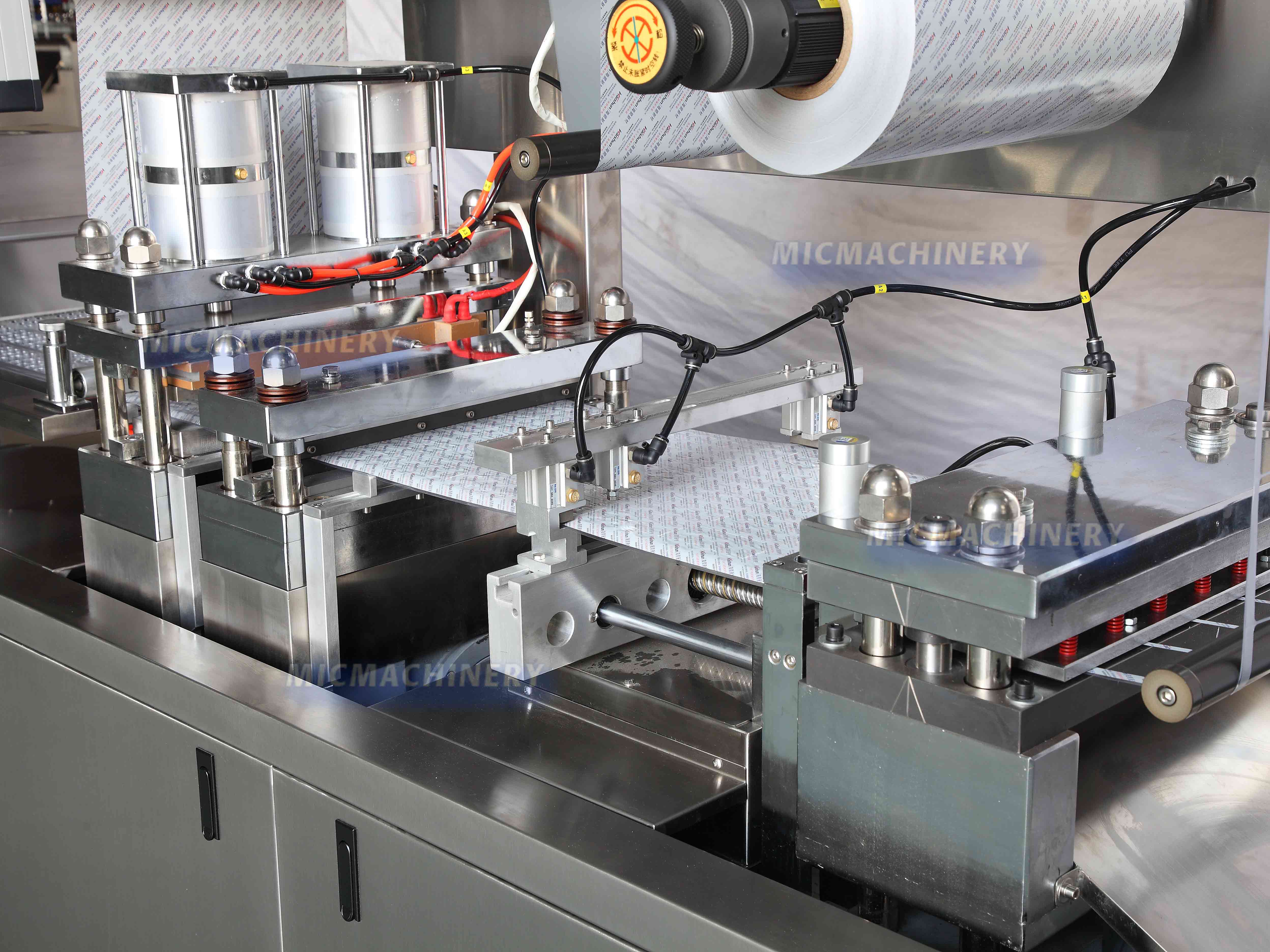

It adopts the newest type high-power transmission mechanism to arrange the chain and drive the main driving shaft. The errors and noises of other gear wheel transmission can be avoided.

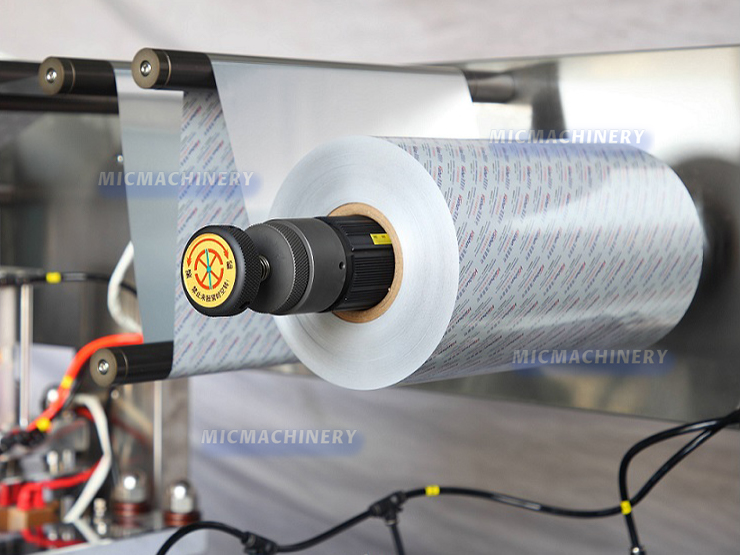

It adopts photoelectrical controlling system to make PVC, PTP, Aluminum/Aluminum material to be automatically fed and waste side to be cut automatically to guarantee the Synchronous stability of over- length distance and multi stations.

It can be optional equipped with photocell correction device, imported stepper motor traction and image- character register to optimize packing grade.

|

Model |

MIC-DPP-420S |

MIC-DPP-420S-II |

|

Photocell (eye marking) system |

Sealing foil eye marking system |

Forming and sealing two sides eye marking system |

|

Suitable for |

|

Specially for surprise egg, cheese stick, and other forming eye marking material |

|

Cutting Frequency (t/min) |

10-35 |

10-35 |

|

Max. Forming Area And Depth (mm) |

390*150*26 |

390*150*26 |

|

Travel Range (mm) |

40-160 |

40-160 |

|

Air Pressure (Mpa) |

0.4-0.7 |

0.4-0.7 |

|

Air Supply |

≥0.35m³/min |

≥0.35m³/min |

|

Total Power |

380V/220V 50Hz 9.7kw |

380V/220V 50Hz 22kw |

|

Main Motor Power (kw) |

2.2 |

2.2 |

|

Material Width (mm) |

0.25-0.5*420 (PVC) 0.02-0.035*420 (ALU FOIL) |

0.25-0.5*420 (PVC) 0.02-0.035*420 (ALU FOIL) |

|

Mould Cooling |

Tap water or circulating water |

Tap water or circulating water |

|

Overall Dimensions (mm) |

4000*950*1600 (L*W*H) |

4500*950*1600 (L*W*H) |

|

Weight (kg) |

1800 |

2000 |