- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Pharmaceutical industry: tablets, capsules, syringes, ampoule, vials, antipyretic stickers, test paper, medical instruments and other packaging.

Food industry: candy, chocolate, cheese, jam, lollipop, jelly, yogurt, surprise eggs and other packaging.

Cosmetics industry: mask, eye paste, hair film, mouthwash and other packaging.

Introduction to Blister Packaging Machines: Efficient and Secure Solutions

Key Features of Blister Packaging Machines

Pricing and Cost Considerations

Specialized Blister Packaging Machines

Conclusion

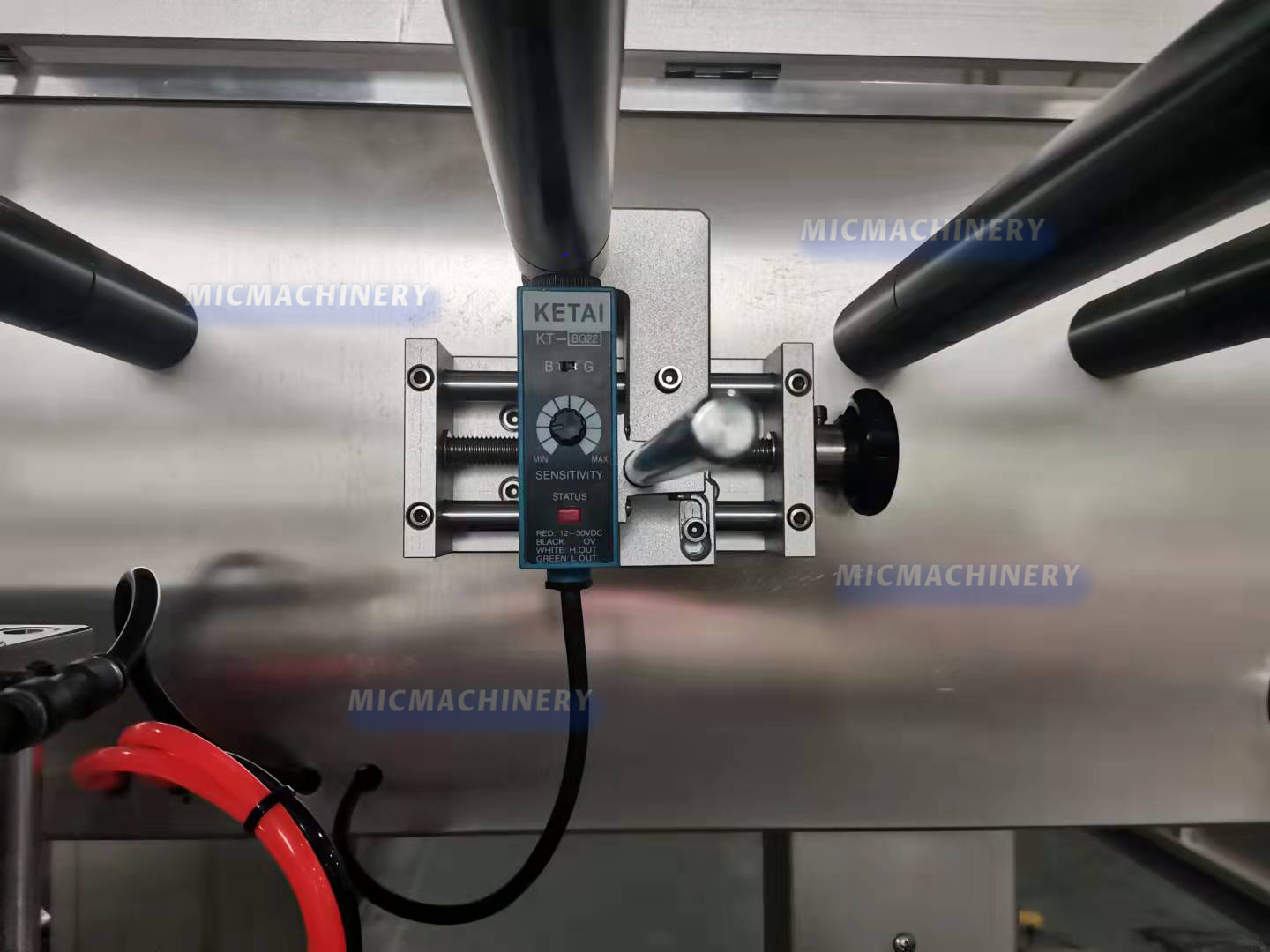

Servo with photoelectric calibration, precise and easy to adjust.

With air blowing cooling function, the plate is not easy to deform after heat sealing.

Heating plate is Teflon coated, non-stick.

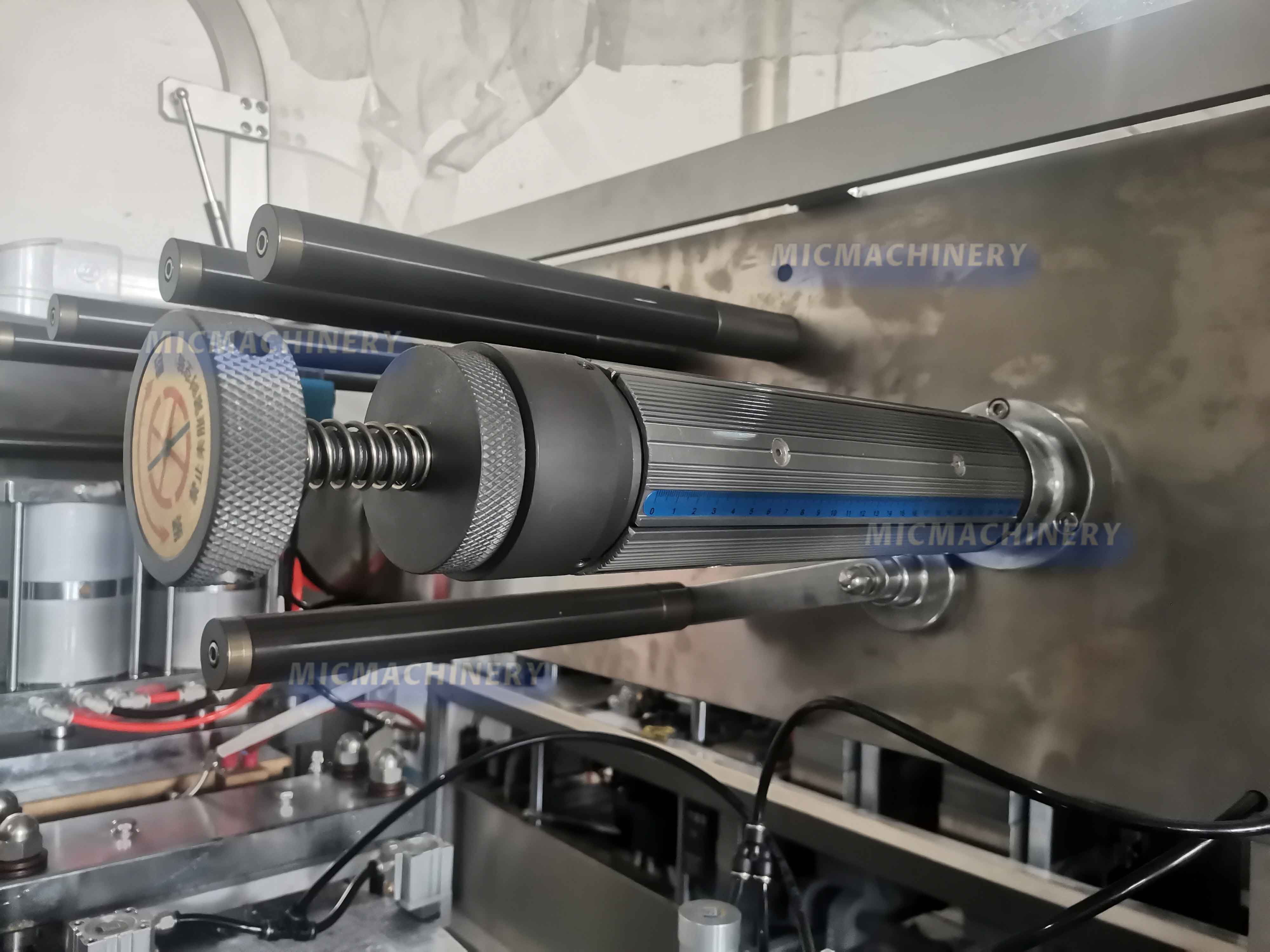

The size can be adjusted according to the size of the material roll, and it is equipped with a ruler for easy recording.

|

Model |

MIC-DPP-250 |

MIC-DPP-260S |

MIC-DPP-260S-II |

MIC-DPP-260D |

|

Traction control system |

Mechanical cam traction |

Servo motor traction |

Servo motor traction and traction lengthened |

Servo motor traction and traction lengthened |

|

Stations |

Four stations: forming, heating, perforation, punching |

Four stations: forming, heating, perforation, punching |

Four stations: forming, heating, perforation, punching |

Five stations: forming, heating, embossing, perforation, punching |

|

Max. Forming Area And Depth (mm) |

240*150*26 |

240*150*26 |

240*180*45 SPECIAL DEPTH MODEL |

240*180*26 |

|

Cutting Frequency (t/min) |

AL-AL: 10-25 AL/PAPER-PVC: 10-50

|

AL-AL: 10-25 AL/PAPER-PVC: 10-50 |

AL-AL: 10-25 AL/PAPER-PVC: 10-50 |

AL-AL: 10-25 AL-PVC/PAPER: 10-50 |

|

Travel Range (mm) |

40-150 |

40-150 |

20-180 |

20-180 |

|

Air Pressure (Mpa) |

0.4-0.7 |

0.4-0.7 |

0.4-0.7 |

0.4-0.7 |

|

Air Supply |

≥0.35m³/min |

≥0.35m³/min |

≥0.35m³/min |

≥0.35m³/min |

|

Total Power |

380V/220V 50Hz 6.4kw |

380V/220V 50Hz 6.4kw |

380V/220V 50Hz 6.4kw |

380V/220V 50Hz 7.6kw |

|

Main Motor Power (kw) |

1.5 |

1.5 |

1.5 |

1.5 |

|

Material Width (mm) |

0.25-0.5*260 (PVC) 0.02-0.035*260 (ALU FOIL) |

0.25-0.5*260 (PVC) 0.02-0.035*260 (ALU FOIL) |

0.25-0.5*260 (PVC) 0.02-0.035*260 (ALU FOIL) |

0.25-0.5*260 (PVC) 0.02-0.035*260 (ALU FOIL) |

|

Mould Cooling |

Tap water or circulating water |

|||

|

Overall Dimensions (mm) |

3000*730*1600 (L*W*H) |

3000*730*1600 (L*W*H) |

3500*730*1600 (L*W*H) |

3900*730*1600 (L*W*H) |

|

Weight (kg) |

1300 |

1300 |

1400 |

1600 |