- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Precision and Efficiency: The Performance of Cartridge CBD Filling Machine

In the burgeoning CBD industry, precision and efficiency are paramount for ensuring product quality and meeting consumer demands. The Cartridge CBD Filling Machine emerges as a critical solution, offering meticulous and efficient filling for CBD cartridges. Let's explore how this equipment optimizes performance, focusing on its role as a cartridge filling machine, silicone cartridge filling machine, and automatic cartridge filling machine.Maximizing Performance with Cartridge CBD Filling Machine

Accurate CBD Cartridge Filling: The Cartridge CBD Filling Machine ensures precise and consistent filling of CBD cartridges with cannabinoid extracts. Equipped with advanced filling mechanisms and controls, this equipment delivers uniform CBD distribution, minimizing product variance and maintaining potency levels.

Tailored for CBD Productivity: Serving as a cartridge filling machine, this equipment is specifically designed to handle CBD cartridges, offering specialized features for cannabinoid product manufacturing. Its precision-engineered components ensure seamless filling operations, maintaining product integrity and quality throughout the process.

Efficiency and Productivity: As an automatic cartridge filling machine, the Cartridge CBD Filling Machine streamlines production processes, improving efficiency and productivity in CBD cartridge manufacturing. Its automated features reduce the need for manual intervention, minimizing labor costs, and maximizing throughput while ensuring precise CBD dosage consistency.

Serving as a Cartridge Filling Machine, Silicone Cartridge Filling Machine, and Automatic Cartridge Filling Machine

Cartridge Filling Machine: The Cartridge CBD Filling Machine serves as a dedicated solution for filling various types of CBD cartridges. Its robust construction and specialized design ensure accurate and efficient filling operations, catering specifically to the unique requirements of the CBD industry.

Silicone Cartridge Filling Machine: While not specifically designed for silicone-based materials, this equipment shares similarities with silicone cartridge filling machines in terms of precision and versatility. Its adaptable design allows for the filling of various cartridge materials, including those used in CBD product packaging.

Automatic Cartridge Filling Machine: With its automatic operation, the Cartridge CBD Filling Machine offers seamless integration into CBD production lines. Operators can program settings and monitor the filling process with ease, while the machine delivers consistent and reliable performance, meeting production demands efficiently.

Conclusion

The Cartridge CBD Filling Machine stands as a testament to precision and efficiency in CBD product manufacturing. Whether serving as a cartridge filling machine, silicone cartridge filling machine, or automatic cartridge filling machine, it plays a pivotal role in optimizing manufacturing processes and ensuring product quality. By investing in this advanced equipment, CBD product manufacturers can streamline operations, reduce costs, and meet consumer expectations with confidence.

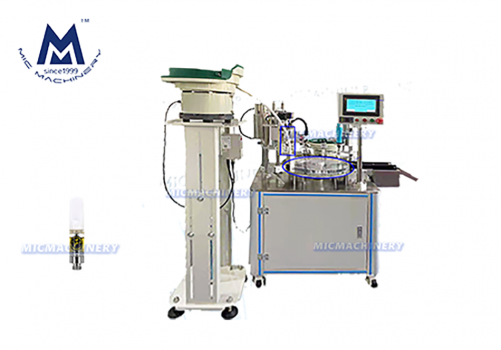

Automatic control of liquid injection / screw cap

pressure cap.

Pure electric control liquid injection work, simple

operation, small area; with high precision, high

efficiency, strong stability and other

characteristics.

1.Touch Screen Cortolled System

2.Rotary Plate Design.

3.L iquid quantitative flling

4.Working Process feding fling loading aps-apping High

precision, no oil leakage.

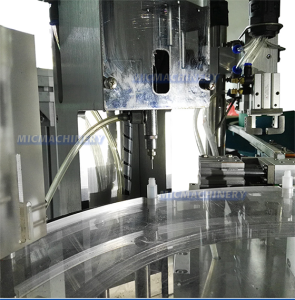

The main platform

The picture includes chuck, negative vacuum filling head,and automatic lid feeding and lid tightening stations.They are clear function and easy to clean.

Among them, the chuck is used to fix the filling container and drive the container to move to the filling capping and other stations. The circular design can save space while setting up multiple positions, so that the filling process is time-saving and efficient.We can customize this turntable, filling head, screw cap and so on.

Negative pressure filling

1. It can keep your finished product level at the same level with very little error. If your product container is made transparent, it can have a better visual effect in sales

2.It can be filled without dripping When filling without dripping, the cosmetic industry also needs to achieve a high standard of hygiene, negative vacuum filling without dripping to avoid the risk of cross infection

3.It is also very suitable for the filling of liquid which is easy to bubble during the filling process. Because this machine will suck all the foam in the bottle mouth at the end. The sucked foam and liquid will enter the liquid storage tank and it will not be wasted.

If you want to know more models of filling machine, you can refer to the table below:

|

Cartridge filling machine |

||||

|

model |

SFC-20 |

SFC-30 |

SFC-35 |

SFZ-50 |

|

application |

glass adhesive,silicon sealant, water-based acrylic glue, free-nail glue, titebond, series of polyurethane materials,etc |

|||

|

Packing type |

aluminum tube,plastic tube,etc |

|||

|

speed |

25-45 pcs/min |

30-35pcs/min |

20-35pcs/min |

40-60pcs/min |

|

Filling arrange |

100-400ML |

75-250ML |

1-310ML |

1-310ML |

|

power |

1.1KW |

|

|

|

|

size |

1500*700*1800mm |

1950*800*1850mm |

4200*1450*2200ML |

5200*1450*2200ML |

|

weight |

500KG |

600KG |

850KG |

1100KG |

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.