- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Mic Machinery proudly introduces the Semi Automatic Vertical Silicone Tube Filling Machine, specially designed to provide a reliable and cost-effective solution for silicone-based product manufacturers. This compact yet powerful machine offers smooth and accurate filling for a variety of viscous materials, including sealants, adhesives, and pastes, making it ideal for medium-scale production.

Outstanding Performance of Our Silicone Filling Machine

Our semi-automatic Silicone Filling Machine is built for precision, flexibility, and durability. It is suitable for various silicone products and is compatible with multiple packaging formats. Key features include:

√ Vertical structure that saves floor space and allows for easy tube placement and filling;

√ Manual-assisted operation for optimal control and minimal product waste;√ Pressure-based filling mechanism suitable for high-viscosity materials like silicone and sealant;

√ Foot pedal activation for convenient filling start/stop during production;

√ Easy-to-clean stainless steel construction that ensures hygiene and longevity.

With these features, the machine offers a perfect balance between automation and manual control, improving product consistency while remaining budget-friendly.

Precision and Flexibility in Silicone Tube Filling Machine

The Silicone Tube Filling Machine is engineered to handle a wide range of tube types and sizes, ensuring that each is filled precisely and cleanly. It allows users to adjust filling volume and speed based on product requirements, helping minimize waste and meet packaging standards. Whether filling single-component silicone or specialty pastes, this machine delivers stable, repeatable performance across batches. Its simple design allows easy switching between different products, making it ideal for flexible production environments.

Versatile Use as a Silicone Sealant Filling Machine

Designed with industry needs in mind, the machine also serves as a dependable Silicone Sealant Filling Machine. It is widely used in the construction, automotive, and home improvement industries where silicone sealants are essential. Highlights of its versatility include:

● Compatibility with both plastic and aluminum cartridges or collapsible tubes;

● Reliable performance for medium-viscosity and high-viscosity sealants;● Accurate nozzle design to prevent dripping and ensure a clean finish;

● Efficient for both professional and DIY-grade silicone sealant production.

This functionality allows manufacturers to meet various market demands while maintaining consistent quality.

Customization and Easy Operation for Maximum Output

Mic Machinery offers flexible configuration options to help you get the most out of your Silicone Filling Machine. These include adjustable filling pressures, customizable nozzles, and adaptable tube holders to fit specific packaging needs. Operators benefit from:

● Simple mechanical adjustments without complex programming;

● Fast changeover between different tube sizes or products;

● Clear visual indicators and minimal training requirements.

Together, these elements make the Silicone Tube Filling Machine an ideal solution for businesses seeking to improve operational efficiency with semi-automated tools.

Reliable Support and Professional Manufacturing from Mic Machinery

At Mic Machinery, we take pride in providing reliable, well-engineered filling solutions that meet the diverse needs of our clients. Our Silicone Filling Machine is built with quality components for durability and low maintenance. Whether you require a high-performance Silicone Sealant Filling Machine or a multi-purpose Silicone Tube Filling Machine, we offer tailored support, fast delivery, and ongoing technical assistance. We are committed to helping manufacturers achieve consistent results, increased productivity, and long-term success.

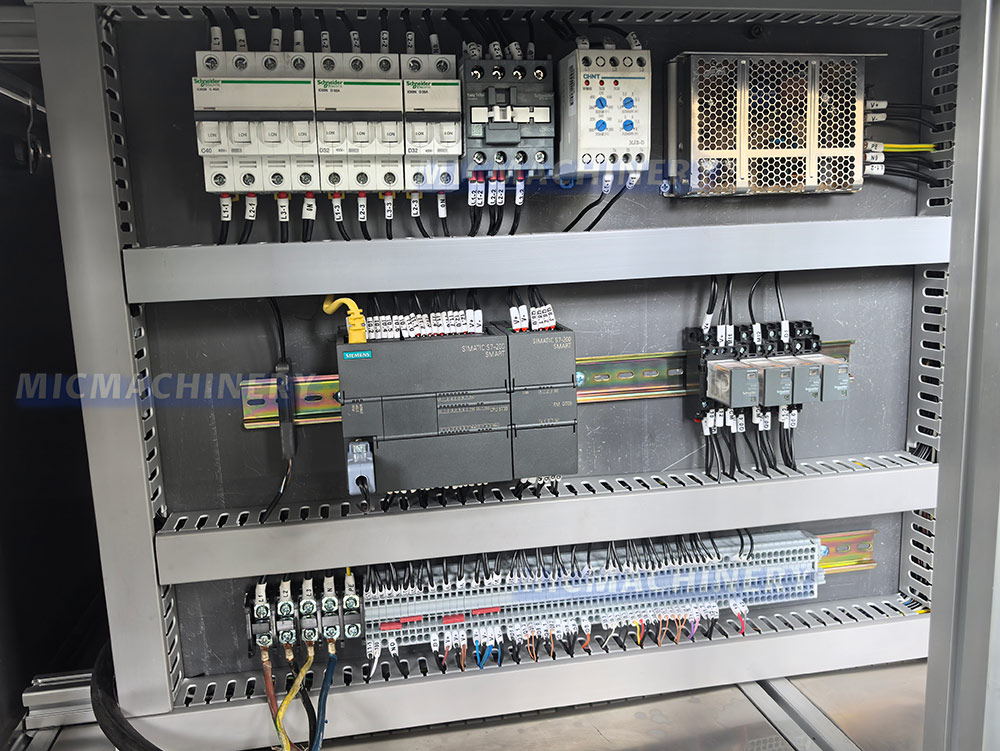

Electrical Machinery

The electrical machinery in the Silicone Filling Machine powers the core components with stable, efficient performance. Designed for reliability and precision, it ensures smooth operation of the motor, pump, and control systems, enabling accurate filling of silicone products with minimal downtime.

Filling head

The filling head in the Silicone Filling Machine is engineered for high precision and smooth dispensing of viscous materials. Its leak-proof, adjustable design ensures clean, accurate filling of tubes or cartridges, making it ideal for silicone, sealants, and similar thick formulations.

Lid Sorting Device

The lid sorting device in the Silicone Filling Machine automatically arranges and feeds lids for precise placement onto tubes or cartridges. Its efficient, vibration-assisted design ensures continuous lid supply, reduces manual handling, and enhances sealing accuracy during the filling process.

|

Filling Volume |

By customized |

|

Suitable Bottle |

φ40-50mm Length 150-230mm |

|

Filling Speed |

15-25 pcs/min |

|

Filling Nozzle |

1*By customized |

|

Power |

4KW |

|

Precision |

±1% |

|

Machine Material |

SUS304 |

|

Machine Weight |

600Kg |

|

Machine Size |

1200*1000*1800mm |

|

PLC |

Siemens/XINJIE(Standard) |

|

Touch Screen |

Siemens /XINJIE(Standard ) |

|

Servo motor |

Delta |

|

Servo driver |

Delta |

|

Frequency converter |

Delta |

|

Encoder |

Omron |

|

Photoelectric switch |

Panasonic |

|

Photoelectric switch |

BFN |

|

Approach Switch |

BFN |

|

Button switch |

Schneider |

|

Intermediate relay |

Schneider |

|

Power switch |

Schneider |

|

Switching power supply |

Omron |

|

Air cylinder |

AirTAC |

|

Electromagnetic valve |

AirTAC |

|

Air switch |

Schneider |

|

AC contactor |

Schneider |

- MIC Single Head Cartridge Filling Machine

- MIC Semi Automatic cartridge filling machine

- MIC Semi Automatic Horizontal Cartridge Filling Machine ( 10-20 Bottles/Min )

- MIC LL30 Semi-Automatic Cartridge Filling Machine

- MIC SF1 Semi Automatic Vertical Cartridge Filling Machine

- MIC LL30 Semi Automatic Horizontal Silicone Cartridge Filling Machine

- MIC Automatic Vertical Cartridge Filling Machine

- MIC Semi Automatic Vertical Silicone Cartridge Filling Machine

- MIC Automatic Single Head Horizontal Cartridge Filling Machine

- MIC Dual Cartridge Sealant Filling Machine (15-23 Cartridges/Min)

- MIC Dual Cartridge Filling Machine ( 15-23 Cartridges/Min)

- MIC Dual Cartridge Filling Machine (40-60 bottles/m)

- MIC Silicone Cartridge Filling Machine (10-30 bottles/m)

- MIC-L60I Automatic Cartridge Filling Machine (50-60 Tubes/m)

- MIC-C30 Cartridge Filling Machine (20-30 Bottles/m)

- MIC-L40 Glue Cartridge Filling Machine (40 Bottles/m)

- Semi Automatic Cartridge Filling Machine (20-30 Bottes/m)

- MIC Cartridge CBD Filling Machine (15-30 Bottles/m)