- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the realm of bottling, precision and efficiency are paramount for maintaining product quality and optimizing production processes. The Rotary Small Bottle Filling Machine emerges as a pivotal solution, offering meticulous and efficient filling for various liquid products. Let's explore how this equipment performs, focusing on its role as a glass bottle filling machine, glass bottling machine, and glass bottle packing machine.

Maximizing Performance with Rotary Small Bottle Filling Machine

Accurate Filling Precision: The Rotary Small Bottle Filling Machine ensures precise and consistent filling for small glass bottles. Equipped with rotary mechanisms and advanced dosing controls, this equipment delivers uniform filling levels, minimizing product variations, and preserving packaging integrity.

Enhanced Efficiency: Serving as a glass bottle filling machine, this equipment optimizes production efficiency by automating the filling process. Its rotary design allows for continuous filling, reducing cycle times and increasing throughput, thus enhancing overall productivity.

Versatile and Reliable Operation: As a glass bottle packing machine, the Rotary Small Bottle Filling Machine offers versatility and reliability. Its adaptable design accommodates various bottle shapes and sizes, catering to diverse packaging requirements while maintaining consistent performance levels.

Serving as a Glass Bottle Filling Machine, Glass Bottling Machine, and Glass Bottle Packing Machine

Glass Bottle Filling Machine: The Rotary Small Bottle Filling Machine serves as a dedicated solution for filling small glass bottles. Its precise engineering and rotary mechanisms ensure accurate dosing and efficient filling, making it an essential asset in glass bottle packaging operations.

Glass Bottling Machine: Specifically designed for glass bottle applications, this equipment automates the bottling process, optimizing packaging efficiency. Its rotary configuration enables seamless integration into production lines, maximizing throughput, and minimizing manual intervention.

Glass Bottle Packing Machine: With its comprehensive filling capabilities, the Rotary Small Bottle Filling Machine offers reliability in packing glass bottles. Whether filling beverages, pharmaceuticals, or cosmetics, this equipment delivers consistent and high-quality filling, meeting diverse market demands with precision and efficiency.

Conclusion

The Rotary Small Bottle Filling Machine represents a fusion of precision, efficiency, and versatility in small bottle packaging. Whether serving as a glass bottle filling machine, glass bottling machine, or glass bottle packing machine, it plays a crucial role in optimizing manufacturing processes and ensuring product quality. By investing in this advanced equipment, manufacturers can streamline operations, reduce costs, and meet consumer demands with confidence, thus establishing a competitive edge in the market.

This E-Liquid filling machine is suitable for:

Oils, liquid alcohol, liquid medicine, oral liquid, cosmetics, skin care products, hair care products, electronic cigarette oil, etc.

This machine function is:

1. Automatic conveyor belt running

2. Automatic bottles feeding

3. Automatic long dropper feeding and loading

4. Automatic Caps capping

5. Automatic double filling heads and filling

6. No bottles no filling

7. No bottles no dropper

8. No bottles no capping

9. Can be customized according to different bottles shape and size

*This machine is mainly available to fill small bottle into various round and flat glass bottle with the range from 10-50ml.

*High precision cam provides a regular plate to position, cork and cap; accelerating cam makes capping heads going up and down; constant turning arm screws caps; peristaltic pump measures filling volume; and touch screen controls all action.

*No bottle no filling and no capping.

*The machine enjoys high position accuracy, stable driving, precise dosage, and simple operation.

*This machine only can be used for glass bottle.

Filling head

When the bottle through the conveyor belt was sent to the location of the chuck, automatic identification of sensors, control by internal program to send signals for filling station, when the bottle comes under the filling head, cylinder head began to move down the drive filling, filling process without dripping, do not waste material, also can ensure the bottle clean and tidy, convenient after labeling.

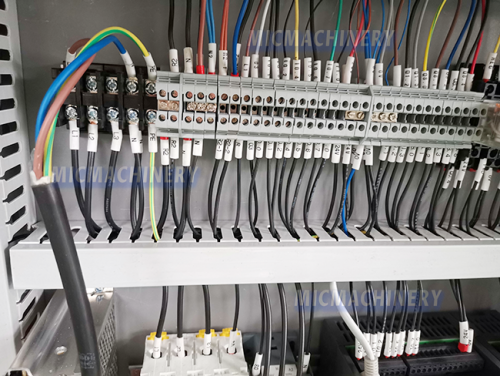

Control panel by Siemens touch screen

The control panel on the filling machine is the core of the machine,it consists of touch screen,power switch, emergency button You just need to press the corresponding button and the machine will follow the correct program.

An Alarm Screen will also be included on automatic filling equipment to notify packagers when there is an issue with the filling equipment or the packaging line in general. In addition to notification, the screen can assist with identifying the issue if the same is not immediately obvious.

If you want to know more models of filling machine, you can refer to the table below:

|

Vial Filling Machine |

||||||||

|

model |

FC-30 |

FC-X40 |

FC-P35 |

FC-P40 |

FC-T30 |

FC-N25 |

FC-E35 |

FC-Z40 |

|

application |

cosmetics, daily chemical and pharmaceutical industries such as nail polish, e-liquid, eye drop,etc |

|||||||

|

Packing type |

various round and flat glass and plastic bottles,etc |

|||||||

|

speed |

23-30 pcs/min |

30-50 pcs/min |

30-40 pcs/min |

25-30 pcs/min |

20-30 pcs/min |

15-25 pcs/min |

30-40 pcs/min |

30-50 pcs/min |

|

Filling arrange |

50-250ML |

10-100 ML |

10-100 ML |

10-100 ML |

30-120 ML |

2-30 ML |

10-100 ML |

20-150 ML |

|

power |

5kw |

2KW |

2KW |

5KW |

2KW |

2KW |

2KW |

2KW |

|

size |

2000*1000*1700mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

2000*1000*1500mm |

|

weight |

650KG |

550KG |

650KG |

650KG |

650KG |

650KG |

650KG |

600KG |

|

Filling Volume |

5-50ml |

Two filling heads |

|

Output |

20-40bottles/min |

According to the size of bottle |

|

Filling type |

Peristaltic pump filling type |

/ |

|

Filling Precision |

≤±1% |

/ |

|

Power Supply |

380V/50Hz |

Can be customized |

|

Capping Rate |

≥99% |

/ |

|

Stoppering rate |

≥99% |

/ |

|

Air Supply |

1.3 m3/h 0.4-0.8Mpa |

/ |

|

Power |

2.0Kw |

/ |

|

Weight |

650 kg |

/ |

|

Dimension |

2100*1000*1500mm |

/ |

|

Parts |

Brand |

|

Press-button |

Schneider |

|

Magnetic Contactor |

Schneider |

|

Relay |

Omron |

|

Frequency Transformer |

Mitsubishi |

|

Motor |

JSCC made in Germany |

|

Air Cylinder |

Airtac |

|

Solenoid Valve |

Airtac |

|

Speed Reducer |

Made in Taiwan |

|

Bearing |

NSK |

|

PLC |

Mitsubishi |

|

Touch Screen |

Mitsubishi |

|

Fibre-optical |

Autonics |

|

Switching Mode Power Supply |

NWELL |

|

Step Motor |

SNAYO made in Japan |