- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

Product Characteristics:

The Lubricant Filling Machine(Motor Oil Filling Machine) stands out with its exceptional product characteristics, embodying the pinnacle of precision and reliability. Crafted from durable and corrosion-resistant materials, this machine ensures longevity and resilience in the demanding lubricant manufacturing environment. Equipped with advanced volumetric or gravimetric filling systems, precision nozzles, and user-friendly interfaces, the machine excels in accurate measurement and dispensing of lubricants. Its adaptability to varying oil viscosities and container sizes, coupled with customizable settings, ensures a tailored and efficient filling process. Anti-drip mechanisms, automatic capping features, and intuitive controls safeguard the quality of lubricants, providing a seamless and precise liquid dispensing experience.

Product Application:

The Lubricant Filling Machine emerges as a versatile solution catering to a diverse spectrum of lubricant manufacturing needs. From engine oils and hydraulic fluids to specialty lubricants, this machine ensures uniformity in dosage and presentation. Its application extends across facilities with varying production volumes, offering an ideal balance between efficiency and adaptability. Whether in small-scale lubricant manufacturing units or large-scale blending operations, the Lubricant Filling Machine plays a pivotal role in delivering consistent and precise lubricating oil solutions.

Mechanical Principle:

At its core, the Lubricant Filling Machine operates on advanced mechanical principles tailored for accuracy and operational ease. Leveraging sophisticated volumetric or gravimetric filling systems, specialized nozzles, and precision controls, the machine accurately measures and dispenses the specified quantity of lubricant into individual containers. Integrated sensors and programmable logic controllers (PLCs) oversee the entire operation, ensuring a flawless and uniform filling process. The conveyor system, intricately designed for efficiency, facilitates the smooth movement of containers, optimizing the overall productivity of the filling process and minimizing errors.

In conclusion, the Lubricant Filling Machine stands as a beacon of efficiency and precision in the lubricant manufacturing landscape. Its distinctive product characteristics, diverse applications, and advanced mechanical principles position it as an indispensable asset in the journey towards seamless and efficient lubricant packaging.

Filling head

The Engine oil is put into the material cylinder, the piston to pump the Engine oil into the measuring cylinder. Then the piston moves up to send the Engine oil to the filling pipe. At the same time, when the bottle enters the filling machine through the conveyor belt, the filling head moves down to start filling. After filling, the conveyor belt will automatically send the bottle to the capping station.

(Filling process without drip leakage, the number of filling head can be customized according to your needs and diameter of filling head basis on the diameter of your barrel’s mouth)

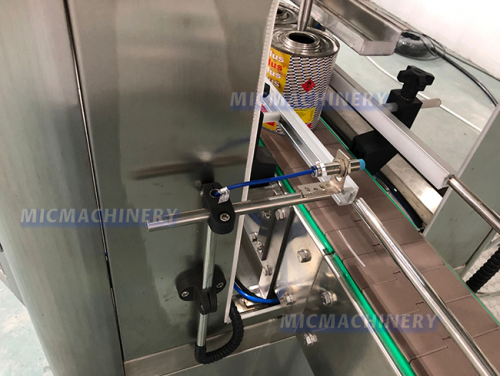

Bottle block air cylinder

When the bottle can reach a certain number, there is a special infrared sensor on the bottle track to receive the induction, and then automatically stuck behind the bottle, in front of the bottle after the bottle filling, and then let the behind the bottle to fill the vacancy, so as to achieve no bottle no filling.

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of bottle,The width between the two pipes can be adjusted according to your container,ensure smooth bottle safely from the conveyor belt moved .

On the side of the conveyor is equipped with sensors that can automatically identify when the bottle to go out or, in order to send signals to filling station of screw cap.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

In addition to,If you're looking for lubricant oil filling machine,lube oil filling machine,lubricant filling machine,engine oil filling machine,motor oil filling machine,lubricant filling line,automatic engine oil filling machine,lubricant oil packing machine price,mobil oil packing machine,automatic lubricant oil filling machine,it is a pleasure for you to visit our website anytime

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.