- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

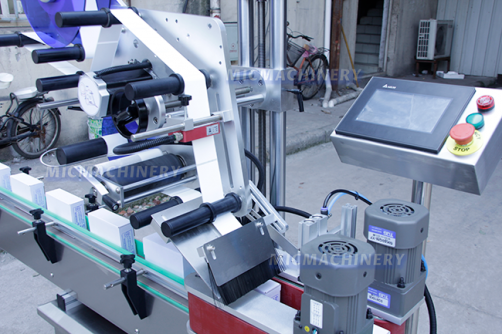

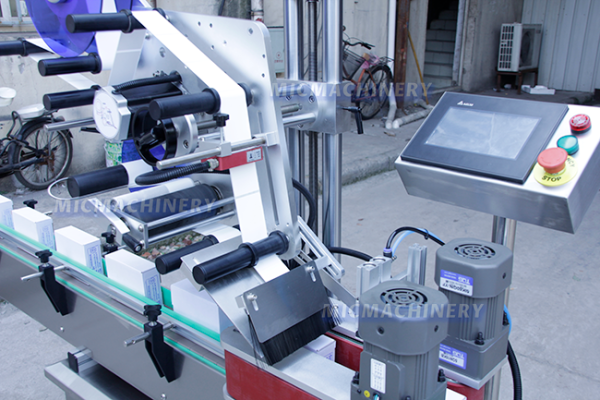

Applicable to all kinds of things on the plane labeling or not film, such as books, folders, boxes, cartons, etc., replaced by the institutions can be applied to uneven surface labeling, widely used in widely used in printing, stationery, food, daily chemical, electronics, medicine, industry such as big plane labeling of products, specifications wide plane class object labeling.It can be equipped with the marking machine or the spraying machine to the label head, which can print the production date, batch number and barcode information on the label.Full-automatic plane labeling machine can be used alone, or connected to the packaging line.

Product features:

◆ wide range of application, can meet the width of products 30mm ~ 350mm of product labeling and dry rubber film, replace the overlaying mechanism can meet the uneven surface labeling;◆ high labeling accuracy, subdivided stepper motor or servo motor drive feed, feed accurate;The design of belt winding rectifying mechanism ensures that the label does not deviate from left to right in the process of traction;Eccentric wheel technology is applied to traction mechanism, traction label does not slip, to ensure accurate marking;

◆ solid and durable, adopt three-bar adjusting mechanism, make full use of triangle stability, the whole machine is solid and durable;

◆ high stability, advanced electronic control system composed of Siemens PLC, Siemens touch screen and imported servo motor, supporting equipment running 7×24 hours;

◆ flexible application, single production or assembly line production, simple production site layout;

◆ intelligent control, automatic photoelectric tracking, with no marking, no marking automatic correction and automatic label detection function, to prevent the leakage and label waste;

◆ touch screen operation interface, full Chinese comments and perfect fault prompt function, easy and quick adjustment of various parameters, easy to operate;

◆ powerful function, with production counting function, power saving function, production number setting prompt function, parameter setting protection function, convenient production management;

◆ optional functions and components:

※ the function of hot typing code/spraying code;

* automatic material receiving function (considering the product);

※ adding labeling device;

※ other functions (customized according to customer requirements)

Working principle:

* core working principle: the sensor detects the passing of the product and sends back the signal to the labeling control system. After the signal is processed by PLC, the label is sent out at an appropriate time to be attached to the set position of the product. The product flows through the overlaying device and the label is covered firmly.* operation process: product placement (line connection) -- > product delivery (automatic realization) -- > product correction (automatic realization) --

product detection (automatic realization) -- > labeling (automatic realization) -- > re-labeling (automatic realization) -- > collection of labeled products.

Labeling worktable

Core principle: putting the product on the conveyor belt,sensors detect the product after, back to the signal to the labeling control system, in the appropriate position control system control corresponding motor send labels and attached with a stay in product labeling position, The product goes through the labeling device, and the attached action of a label is completed.

High precision labeling

High labeling accuracy, subdivision stepper motor or servo motor drive to send the label, precise feeding; The design of deviation correction mechanism for label belt ensures no deviation from left to right in the process of label traction; Eccentric wheel technology applied to traction mechanism, traction label does not slip, to ensure accurate marking

In addition to,If you're looking for labeling machine,bottle labeling equipment,sticker labelling machine price,labelling equipment,automatic labeling machine,sticker labeling machine,automatic labelling machine,commercial labeling machine,+labeling +machine,+automatic +labeling +machine,Please feel free to visit our website.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

model |

RXL-P |

|

Tape size |

The length of the 40-500 - mm

The width of the 40-200 - mm

The thickness of 1-300 - mm

|

|

Drive way |

Stepper motor |

|

Labeling speed |

50 meters/min |

|

Label size |

H:20-80mm/20-150mm L:20-200mm |

|

Labeling accuracy |

±1.5mm |

|

machine size |

2000*900*1450 |

|

Weight (kg) |

200Kg |

|

power supply |

AC110V/220V 50/60HZ 950W |

|

Part name |

brand |

|

Label servomotor |

panasonic |

|

Label the motor drive |

panasonic |

|

Conveyor belt motor |

Shanghai built inscription |

|

Labeling photoelectric |

omron |

|

Label detection photoelectric |

lao yi ce |

|

Programmable controller (PLC) |

Siemens (Germany) |

|

Man-machine interface |

Siemens (Germany) |

|

inverter |

Siemens (Germany) |

|

Synchronous toothed belt |

Japan samsung |

|

cabinet |

S304 stainless steel |

- Round Bottle Labeling Machine

- MIC-PT60 Automatic horizontal way labeling machine

- Automatic front&back sides labeling machine

- Sleeve labeling machine

- High speed servo horizontal labeling machine

- Location labeling machine

- Vertical round bottle sticker labeling machine

- Flat adhesive labeling machine

- High speed adhesive labeling machine

- Paging adhesive labeling machine

- Single-sided adhesive labeling machine

- Double-sided adhesive labeling machine

- Location labeling machine

- Sticker Labeling Machine