- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the contemporary landscape, where hygiene is of utmost importance, ensuring the efficient and accurate packaging of hand sanitizers is crucial. The Hand Sanitizer Bottle Filling Machine stands as a pivotal solution, offering precise filling capabilities tailored to the demands of hygiene product manufacturing. Let's explore its performance, emphasizing its role as a hand sanitizer filling machine, hand sanitizer bottle filling machine, and contributor to a hand sanitizer filling line.

Optimizing Performance with Hand Sanitizer Bottle Filling Machine

Accurate Dispensing: The Hand Sanitizer Bottle Filling Machine excels in dispensing hand sanitizer into bottles with remarkable precision. Equipped with advanced dosing mechanisms and controls, it ensures uniform and accurate filling, a vital aspect for maintaining product consistency and efficacy in hygiene formulations.

Streamlined Operation: As a specialized machine, it is engineered for streamlined operation, optimizing efficiency without compromising accuracy. With user-friendly interfaces and customizable settings, operators can easily adjust parameters to accommodate various bottle sizes and fill volumes, enhancing production flexibility and productivity.

Flexibility and Adaptability: Serving as a key component in a hand sanitizer filling line, this machinery offers versatility in handling different bottle types, sizes, and packaging configurations. Whether filling small travel-sized bottles or larger containers, it adapts seamlessly to diverse production requirements, facilitating smooth and efficient operations in hygiene product manufacturing.

Serving as a Hand Sanitizer Filling Machine, Hand Sanitizer Bottle Filling Machine, and Hand Sanitizer Filling Line

Hand Sanitizer Filling Machine: The Hand Sanitizer Bottle Filling Machine serves as a dedicated solution for accurately and efficiently filling hand sanitizer products. Its robust construction and precise dosing mechanisms ensure consistent fills, minimizing product wastage and maximizing dosage accuracy for hygiene formulations.

Hand Sanitizer Bottle Filling Machine: Tailored specifically for bottle filling applications, this equipment excels in handling hand sanitizer formulations with precision. Its sterile filling capabilities and adherence to regulatory standards ensure the safety, quality, and efficacy of hygiene products, meeting the stringent requirements of hand sanitizer manufacturing.

Hand Sanitizer Filling Line: As an integral part of a hand sanitizer filling line, this machinery contributes to the seamless operation of the production process. Integrated with bottle feeding systems, filling stations, capping machines, and labeling systems, it enables end-to-end automation, optimizing efficiency and throughput while maintaining product integrity and compliance.

Conclusion

The Hand Sanitizer Bottle Filling Machine plays a pivotal role in hygiene product manufacturing, offering precision, efficiency, and adaptability in bottle filling operations. Whether serving as a hand sanitizer filling machine, hand sanitizer bottle filling machine, or component of a hand sanitizer filling line, it ensures the quality and integrity of hygiene products. By investing in this advanced equipment, hygiene product manufacturers can enhance their production capabilities, meet market demands, and uphold their commitment to delivering high-quality and effective hand sanitizer products to consumers.

This syrup filling machine is suitable for:

A variety of small doses of liquid filling & capping such as medical alcohol, oil, injection. Widely used in food, pharmaceutical, chemical industries and scientific research.

This machine is built in the absorption of foreign advanced technology, based on independently developed by our company.

This machine is suitable for a variety of small doses of liquid filling & capping such as oil, injection. Widely used in food, pharmaceutical, chemical industries and scientific research.

Full compliance with the GMP requirements.

Main Features Of MIC-L40 automatic e-liquid bottle filling capping and labeling machine

1. Microcomputer setting, high filling accuracy

2. The main engine is equipped with stepless frequency speed control.

3. Automatic production capacity quantitative control.

4. With all kinds of fault alerting, for low pressure, no filling, no inner cap etc.

5. The machine can stop automatically in case of no filling, no inner cap etc.

Filling head

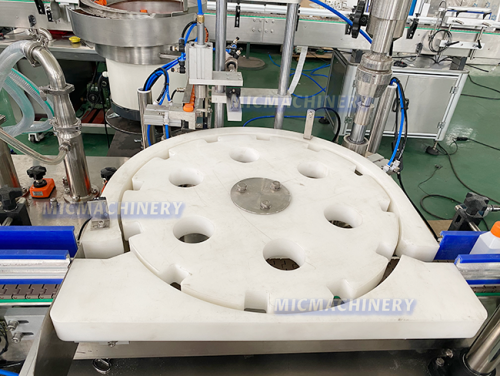

The bottle through the conveyor belt was sent to the location of the filling head, automatic identification of sensors, control by internal program to send signals for filling station, Start precise quantitative filling, filling process without dripping, do not waste material, also can ensure the bottle clean and tidy.

Cover loading automatically

Cover feeding cage with vibrating disk is connected to a pipe that carries the outside cover ,They automatically arranges the outside cover and deliver the outside cover.

In this way, the small bottle is covered in a Coherent process, reducing the manual contact with the syringe process, and ensuring bottle hygiene,At the same time, labor costs are reduced.

Bottle block air cylinder

When the bottle can reach a certain number, there is a special infrared sensor on the bottle track to receive the induction, and then automatically stuck behind the bottle, in front of the bottle after the bottle filling, and then let the behind the bottle to fill the vacancy, so as to achieve no bottle no filling

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback:

|

Filling volume |

5-100ml |

|

Loading error |

≤ ±1% |

|

Rotation (rolling) Cover pass rate |

≥99% |

|

Production capacity |

30-50BPM |

|

60-90BPM |

|

|

Power supply |

380V/50Hz |

|

Power |

2.0 kw |

|

Weight |

600 kg |

|

Dimension |

2000*1000*1500mm |

|

Name |

Brand |

|

Press-button |

Schneider |

|

Magnetic Contactor |

Schneider |

|

Relay |

Omron |

|

Frequency Transformer |

Mitsubishi |

|

Motor |

JSCC made in Germany |

|

Air Cylinder |

Airtac |

|

Solenoid Valve |

Airtac |

|

Speed Reducer |

Made in Taiwan |

|

Bearing |

NSK |

|

PLC |

Mitsubishi |

|

Touch Screen |

Mitsubishi |

|

Fibre-optical |

Autonics |

|

Switching Mode Power Supply |

NWELL |

|

Step Motor |

SNAYO made in Japan |