- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In today's hygiene-focused landscape, the efficient and accurate packaging of hand sanitizers is paramount. The 8 Heads Linear Hand Sanitizer Filling Line represents a cutting-edge solution, offering precision filling capabilities tailored to the demands of hygiene product manufacturing. Let's delve into its performance, emphasizing its role as a hand sanitizer filling machine, hand sanitizer bottle filling machine, and contributor to a hand sanitizer filling line.

Maximizing Performance with 8 Heads Linear Hand Sanitizer Filling Line

Accurate Dispensing: The 8 Heads Linear Hand Sanitizer Filling Line excels in dispensing hand sanitizer into bottles with remarkable precision. Equipped with eight filling heads, each meticulously calibrated, it ensures uniform and accurate filling, critical for maintaining product consistency and efficacy in hygiene formulations.

High Throughput: As a linear filling line, this equipment boasts high throughput capabilities, significantly reducing production time and enhancing efficiency. With simultaneous filling operations across multiple heads, it optimizes throughput, enabling rapid and continuous production of hand sanitizer bottles.

Customizable Configuration: Serving as a comprehensive hand sanitizer filling line, it offers flexibility in configuration to meet diverse production requirements. From bottle feeding systems to capping machines and labeling stations, each component is tailored for seamless integration, ensuring smooth and efficient operations from start to finish.

Serving as a Hand Sanitizer Filling Machine, Hand Sanitizer Bottle Filling Machine, and Hand Sanitizer Filling Line

Hand Sanitizer Filling Machine: The 8 Heads Linear Hand Sanitizer Filling Line serves as a specialized solution for accurately and efficiently filling hand sanitizer products. Its precise dosing mechanisms and controls ensure consistent fills, minimizing product wastage and maximizing dosage accuracy for hygiene formulations.

Hand Sanitizer Bottle Filling Machine: Tailored specifically for bottle filling applications, this equipment excels in handling hand sanitizer formulations with precision. Its sterile filling capabilities and compliance with regulatory standards guarantee the safety, quality, and efficacy of hygiene products, meeting the stringent requirements of hand sanitizer manufacturing.

Hand Sanitizer Filling Line: As a comprehensive hand sanitizer filling line, this machinery encompasses multiple components, including bottle feeding systems, filling heads, capping machines, labeling stations, and conveyor systems. Its modular design allows for seamless integration and customization, providing a complete solution for hygiene product manufacturers to streamline their filling processes and ensure product quality and compliance.

Conclusion

The 8 Heads Linear Hand Sanitizer Filling Line plays a pivotal role in hygiene product manufacturing, offering precision, efficiency, and flexibility in bottle filling operations. Whether serving as a hand sanitizer filling machine, hand sanitizer bottle filling machine, or component of a hand sanitizer filling line, it ensures the quality and integrity of hygiene products. By investing in this advanced equipment, hygiene product manufacturers can enhance their production capabilities, meet market demands, and uphold their commitment to delivering high-quality and effective hand sanitizer products to consumers.

This machine is suitable for filling water and cream products, especially for high viscosity materials (such as washing liquid, suspending agent, colloidal suspension agent, oil , cream ,etc.) the effect is obvious. PLC programming control, with a touch screen and man-machine interface system; automatic bottle feeding, automatic filling, automatic bottle; the servo motor drive, double screw drive, the control piston rod movement to ensure the filling stability, filling accuracy higher. It can be with the capping machine, labeling machine supporting the formation of water production line. It integrates light, machine, electricity and gas into one body. Is an easy to operate filling machine. With stable and reliable operation, high production efficiency, strong adaptability.

This machine function is:

1. Automatic bottle sensing system and filling

2. No bottle no filling

3. Filling error is control within 1‰

4. Automatic filling volume correction system.

5. Can be customized for different bottle and caps.

6. Can be equipped with cleaning system.

Gel filling machine Mainly Shows:

1.Place the bottle on the conveyor belt

2.servo motor piston filling when the bottle reaches the designated position

3.Cover hanging machine cover hanging

4.Screw the bottle cap by six wheels

5.at the last, capped bottles come out at the conveyor belt

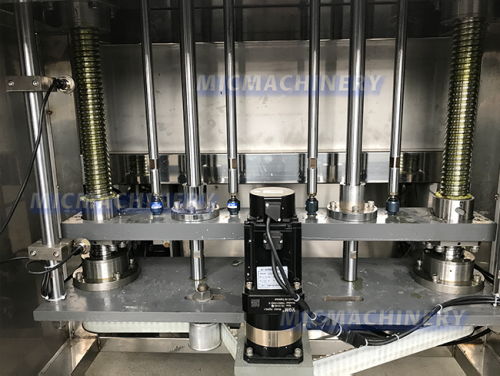

filling head

The gel is put into the material cylinder, and the piston to pump the gel into the measuring cylinder. Then the piston moves up to send the gel to the filling pipe. At the same time, when the bottle enters the filling machine through the conveyor belt, the filling head moves down to start filling. After filling, the conveyor belt will automatically send the bottle to the capping station.

(Filling process without drip leakage, the number of filling head can be customized according to your needs and diameter of filling head basis on the diameter of your barrel’s mouth)

Measuring cylinder

The function of measuring cylinder cylinder is mainly quantitative filling, its use can make your filling accuracy higher, driven by servo motor, control the movement of the piston rod, the Piston moving down extract the material from the material cylinder to the measuring cylinder cylinder, and then the piston moves up to the dose of the cylinder cylinder in the material to the filling pipeline.

(The size of dose cylinder can be customized according to your needs)

Servo motor

This filling machine adopts servo motor drive, servo motor high efficiency, small volume and relatively high power, can drive the machine more stable, smooth filling. In addition, the servo motor operation noise is small, will not cause too much noise burden to the workshop.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Filling head |

8 heads |

|

Filling volume range |

50-1000ml(Use 1000ml piston cylinder) |

|

Production speed |

≤1800 Bph basis on 1000ml bottle |

|

Voltage |

220v/380v |

|

Power |

3kw |

|

Suitable bottle’s diameter |

Ф40mm-Ф100mm |

|

Filling error |

≤±1 |

|

Work pressure |

0.55Mpa-0.65Mpa |

|

Size |

2000mm × 1400mm× 2500mm |

|

Weight |

1000kg |

|

Touch screen |

Canada xinjie color |

|

PLC |

Schneider |

|

Solenoid valve |

Taiwan Airtac |

|

Optoelectronic system |

OPTEX |

|

Micro differential pressure switch |

Netherlands |

|

Servo motor |

Taiwan TECO |

|

Air source treatment |

Taiwan Airtac |

|

Button and low voltage electric appliance |

Schneider |

|

Ball screw |

Taiwan |

|

Reducer |

Taiwan VGM |

|

Switching power supply |

Taiwan meanwell |

|

Material |

Contact with the material parts of the 316 materials, and the rest of the 304 stainless steel |