- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

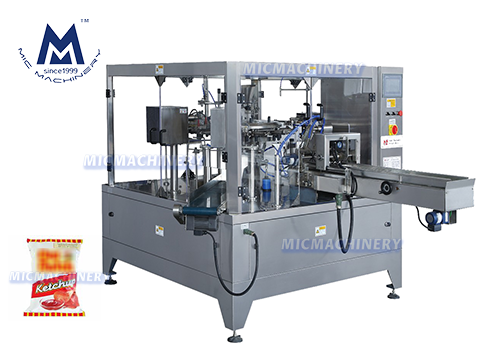

In the fast-paced world of food manufacturing, precision and speed are crucial elements that define success. Introducing the Ketchup Packaging Machine – a revolutionary marvel engineered to perfection. This state-of-the-art device combines cutting-edge technology with seamless functionality, redefining the standards of ketchup packaging. Let’s explore the distinct product characteristics, diverse applications, and the intricate mechanical principles that make the Ketchup Packaging Machine an indispensable asset for food businesses worldwide.

Product Characteristics:

The Ketchup Packaging Machine is characterized by its exceptional design and efficiency. Crafted from high-quality materials, these machines are built to endure the demands of rigorous production environments. Their customizable features allow for various packaging options, from individual sachets to bulk containers, catering to diverse market needs. Equipped with advanced dosing systems, these machines ensure precise and consistent filling, minimizing product wastage and maximizing resource utilization. Additionally, user-friendly interfaces enhance operational efficiency, enabling quick adjustments and seamless control. Leak-proof sealing mechanisms preserve the freshness and flavor of the ketchup, ensuring the end product reaches consumers in optimal condition.

Product Applications:

The applications of the Ketchup Packaging Machine are vast and versatile, making it an essential tool for numerous sectors in the food industry. From large-scale food production facilities to small-scale businesses, these machines streamline the ketchup packaging process. Fast-food chains, restaurants, and catering services benefit from the machine’s ability to maintain portion control, ensuring consistency in taste for their customers. Retailers appreciate the neatly packaged, ready-to-sell ketchup bottles and sachets, enhancing shelf appeal and consumer convenience. Moreover, these machines are not limited to ketchup; they can efficiently package a variety of sauces, condiments, and dressings, making them indispensable across different culinary applications.

Mechanical Principle:

At its core, the Ketchup Packaging Machine operates on intricate mechanical principles designed for precision and speed. Utilizing advanced conveyor systems and filling heads, the machine accurately measures and dispenses the specified quantity of ketchup into containers. These machines incorporate sensors and automation, ensuring consistent filling levels and seamless packaging. Sealing mechanisms, employing heat or pressure, secure the containers, preserving the freshness and taste of the ketchup. Advanced control systems oversee the entire process, guaranteeing reliability and minimizing errors, making the packaging process both efficient and cost-effective.

In conclusion, the Ketchup Packaging Machine represents the epitome of innovation and reliability in the food packaging industry. Its outstanding product characteristics, diverse applications, and advanced mechanical principles make it a cornerstone for businesses aiming for precision, efficiency, and quality in packaging ketchup and related products. Embracing the latest advancements, this machine not only meets but exceeds the expectations of both manufacturers and consumers in the ever-evolving culinary landscape.

2.Automatic detection function, if the bag is not opened or opened incompletely, no feeding, no heat sealing, the bag can be reused, no waste of materials, saving production costs for users.

3.The safety device will give an alarm when the working air pressure is abnormal or the heating pipe fails.

4.Equipped with plexiglass safety door to protect operators.

5.Oil-free vacuum pump is adopted to avoid pollution of the production environment.

Suitable for milk powder,coffee,flour,spices,additive,pesticide,chemical powder weighing filling packing for premade bag,zipper bag.

Adopting PLC control,it has the advantages of stable operation and high weighing accuracy.

The width of the bag is easy to adjust and can be controlled with just one button.

Comply with GMP requirements, environmental protection and pollution-free.

All contact parts are made of 304/316 stainless steel.

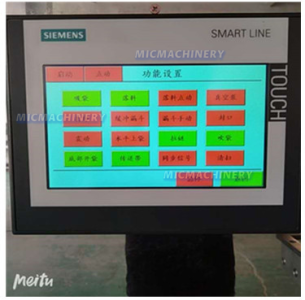

Control panel

The control panel on the filling machine is the core of the machine,it consists of touch screen,power switch, emergency button You just need to press the corresponding button and the machine will follow the correct program.

An Alarm Screen will also be included on automatic filling equipment to notify packagers when there is an issue with the filling equipment or the packaging line in general. In addition to notification, the screen can assist with identifying the issue if the same is not immediately obvious.

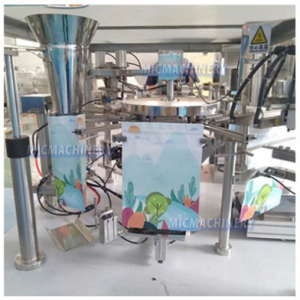

Automatic bag opening device

Its main function is to open the bag and prepare the filling material.

Main work flow: suction cup will bring the bag to the main rotary plate, the main rotary plate holds the bag into the vacuum bag opening station. The bag is vacuumed by suction cups and assists in blowing air out. After the bag is opened, the filling begins, then the bag is sealed, and the final product is conveyed out of the filling machine through a conveyor belt.

In addition to,we have ketchup packaging machine,tomato paste packaging machine,ketchup filling machine,tomato paste sachet packing machine,ketchup packet filling machine,ketchup sachet packing machine,ketchup pouch filling machine,ketchup packing machine,tomato sauce packing machine,sauce pouch packing machine.

If you are more than interested in the machine ,you can contact us at market@micmachinery.com

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Bag material |

Compound mold |

||

|

Bag type |

Zipper free standing |

||

|

Bag size |

W: 100-210mm L: 100-350mm |

W:150-260mm L:150-350mm |

W200-300mm L:200-450mm |

|

Speed |

10-50bag/min |

10-40bag/min |

10-40bag/min |

|

Weight |

1200KG |

1400KG |

1500KG |

|

Voltage |

380V 3 Phase 50HZ/60HZ |

||

|

power |

3KW |

4KW |

4KW |

|

Compressed air |

0.6m ³ /min |

||

- MIC-ZF20 Ketchup Filling Machine ( Sauce, Mayonnaise, Edible Oil, 4000 Bottles/h )

- MIC Rotary Tomato Ketchup Filling Machine ( Sauce, Mayonnaise, 12000 Bottles/h )

- MIC Ketchup Packaging Machine ( Ketchup, Honey, Sauce, 10-50 Bags/min )

- MIC Ketchup Sachet Packing Machine ( Sauce, Ketchup, 20-40 Bags/miin )

- MIC Tomato Paste Packing Machine ( Yogurt, Sauce, Jam, 30-35 Cups/min )

- MIC Ketchup Pouch Packing Machine ( Ketchup, Sauce, Beverage, 3000 Bottles/h )