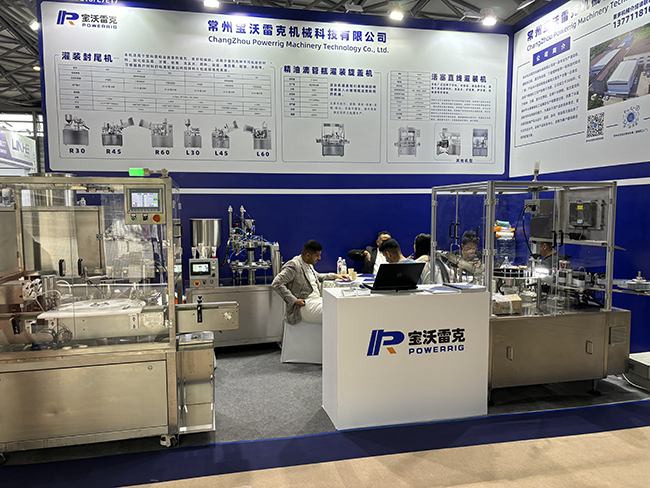

Shanghai Beauty Expo: A Gateway to Innovation in Cosmetic Machinery

The Shanghai Beauty Expo stands as one of the most prestigious events in the cosmetics and beauty industry, drawing professionals, manufacturers, and innovators from around the globe. This year's expo promises to be an exceptional showcase of the latest advancements in beauty technology, focusing on machinery that enhances production efficiency and product quality. For companies operating in the competitive beauty sector, having access to cutting-edge machinery is essential for staying ahead of trends and meeting the evolving demands of consumers.Highlighting Our Main Products

At this year's expo, our company is thrilled to present a comprehensive range of innovative filling machines specifically designed for the cosmetics industry, including:

1. Tube Filling Machines Our tube filling machines are engineered for high precision and efficiency, making them ideal for products such as creams, gels, and ointments. These machines feature versatile filling options that accommodate various tube sizes and materials, including plastic and aluminum. Equipped with advanced automation technology, they minimize the risk of human error and increase productivity. The integration of features like automatic sealing and easy-to-use interfaces allows manufacturers to streamline operations while maintaining high standards of quality. With global sales reaching markets in Europe, North America, and Asia, our tube filling machines are recognized for their reliability and performance.

With global sales reaching markets in countries such as China, the United States, Germany, France, the United Kingdom, Japan, South Korea, India, Brazil, and Australia, our tube filling machines are recognized for their reliability and performance.

2. Syringe Filling Machines Precision is critical when it comes to the production of cosmetic syringes, especially for products that require accurate dosage. Our syringe filling machines are meticulously designed to deliver consistent results, minimizing waste and ensuring compliance with stringent industry standards. These machines are perfect for filling products like serums and targeted treatments, offering customization options to meet specific production needs. Their adaptability has made them popular in markets such as South Korea, Japan, and the United States, where the demand for high-quality cosmetic applications is on the rise.

Their adaptability has made them popular in markets such as South Korea, Japan, the United States, Germany, and Italy, where the demand for high-quality cosmetic applications is on the rise.

3. Syrup Filling Machines As the popularity of liquid cosmetics and treatments continues to rise, our syrup filling machines provide the perfect solution for manufacturers aiming to produce liquid formulations efficiently. Capable of handling a variety of viscosities—from water-thin liquids to thicker creams—these machines incorporate advanced filling technology to maintain product integrity and quality. Their reliability and adaptability make them invaluable for businesses looking to expand their product lines in the increasingly competitive liquid cosmetic market. Our syrup filling machines are currently being sold to countries across Europe, Asia, and Australia, supporting a diverse range of beauty applications.

Our syrup filling machines are currently being sold to countries across Europe, Asia, Australia, Mexico, Brazil, and the United Arab Emirates, supporting a diverse range of beauty applications.

Our vial filling machines have gained traction in markets in North America, the Middle East, Southeast Asia, Russia, and Turkey, where there is a growing demand for specialized cosmetic products.

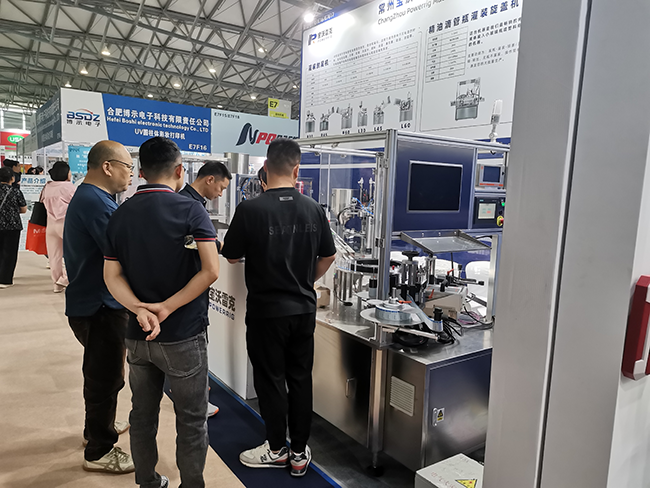

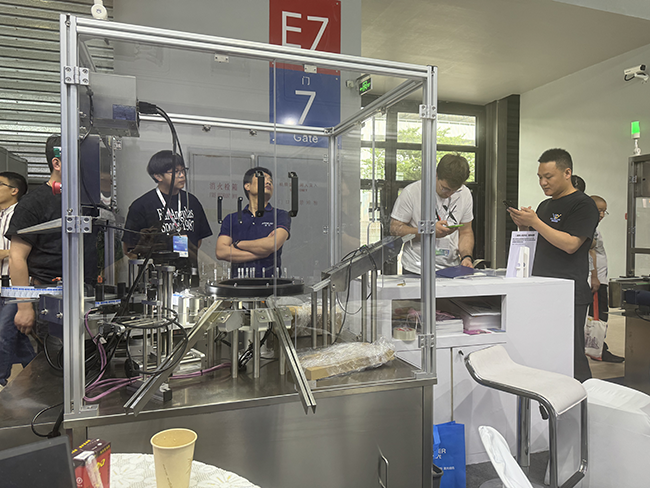

Attending the Shanghai Beauty Expo provides a unique opportunity for industry professionals to network, discover new trends, and explore innovative solutions in cosmetic machinery. Here are some key benefits of participating in the expo:

2. Latest Industry Trends: Stay updated on the latest advancements in cosmetic technology and product formulations, ensuring your business remains competitive in a rapidly evolving market. Understanding emerging trends can help you innovate and respond to changing consumer preferences.

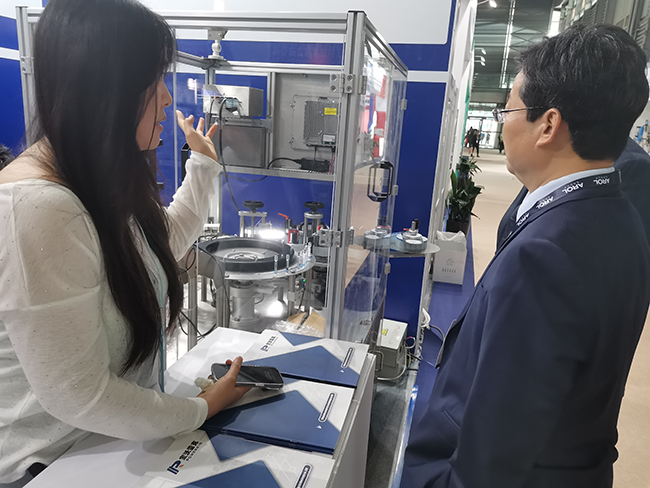

3. Live Demonstrations: Experience live demonstrations of our filling machines and witness firsthand how they can enhance production efficiency and product quality. Seeing the machines in action allows potential customers to gauge their effectiveness and suitability for their specific needs.

4. Educational Seminars: Participate in seminars and workshops hosted by industry experts, covering topics ranging from production efficiency to regulatory compliance. These sessions offer insights that can help you navigate challenges in the beauty sector.

5. Market Insights: Gain valuable market insights and intelligence that can inform your business strategies and decision-making. Understanding the competitive landscape can help you identify new opportunities for growth.

Conclusion

The Shanghai Beauty Expo serves as a vital platform for professionals in the beauty and cosmetics industry. With our focus on high-quality filling machines such as tube filling machines, syringe filling machines, syrup filling machines, and vial filling machines, we are dedicated to helping manufacturers optimize their production processes. By participating in the expo, you can discover how our innovative solutions can elevate your business and meet the growing demands of consumers in the beauty market.

Whether you are a manufacturer looking to upgrade your equipment or a professional seeking insights into the latest trends, the Shanghai Beauty Expo is an event you won't want to miss. Join us and explore the future of cosmetic machinery, where innovation meets quality and efficiency. Together, let's shape the next generation of beauty products and set new standards in the industry.

In the realm of manufacturing and packaging, filling machines play a crucial role in ensuring efficiency, accuracy, and consistency. They are essential across various industries, including pharmaceuticals, cosmetics, food and beverage, and chemical manufacturing. In this article, we will delve into four specific types of filling machines: tube filling machines, syringe filling machines, vial filling machines, and syrup filling machines. We will explore their features, operational processes, and the benefits they offer.

Tube Filling Machines

Overview and Features

Tube filling machines are designed to automate the process of filling and sealing tubes with products ranging from creams and gels to ointments and pastes. They are widely used in the cosmetics and pharmaceutical industries. Key features of tube filling machines include:

1. Versatility: Capable of handling various tube materials, including plastic, aluminum, and laminated tubes.

2. Automatic Controls: Many machines come with programmable logic controllers (PLCs) for easy operation and monitoring.

3. Volume Control: Advanced filling systems ensure precise volume control, which is essential for maintaining product consistency.

4. Sealing Mechanisms: Various sealing options, such as ultrasonic sealing or crimping, ensure that the tubes are securely closed.

5. Labeling Systems: Some machines include integrated labeling systems to streamline production.

The operation of a tube filling machine typically involves the following steps:

1. Feeding Tubes: Tubes are loaded into the machine either manually or automatically.

2. Filling: The product is dispensed into the tube through a filling nozzle. The volume can be adjusted based on product requirements.

3. Sealing: Once filled, the tube is sealed using the chosen sealing method.

4. Labeling: After sealing, the tube may be labeled automatically before being packaged for shipment.

1. Increased Production Speed: Tube filling machines significantly speed up the filling process, allowing manufacturers to meet high-demand production needs.

2. Reduced Labor Costs: Automation reduces the need for manual labor, lowering overall operational costs.

3. Enhanced Accuracy: Precise volume control minimizes product wastage and ensures that each tube is filled consistently.

4. Improved Product Quality: A sealed tube protects the product from contamination and extends its shelf life.

Overview and Features

Syringe filling machines are essential in the pharmaceutical and healthcare sectors, where they are used for filling syringes with vaccines, medications, and other sterile products. These machines must meet strict regulatory requirements for cleanliness and precision. Key features include:

1. Aseptic Design: Constructed to maintain sterile conditions, often with a laminar flow hood or cleanroom compatibility.

2. High Precision: Equipped with advanced metering systems to ensure accurate dosing.

3. Compatibility: Able to accommodate different syringe sizes and types, including prefilled syringes.

4. Automatic Capping: Many machines feature automated systems for capping syringes after filling.

The operation of a syringe filling machine generally follows these steps:

1. Syringe Loading: Syringes are placed in designated holders within the machine.

2. Filling: A precision pump fills each syringe with the required dosage of liquid.

3. Capping: After filling, the machine automatically caps each syringe to maintain sterility.

4. Quality Control: Machines often incorporate quality control checks to ensure each syringe meets specifications.

1. Sterile Filling: Ensures that products are filled in a sterile environment, reducing contamination risks.

2. Increased Efficiency: Automating the filling process enhances production efficiency and throughput.

3. Accurate Dosage: High precision in filling improves patient safety by ensuring the correct dosage.

4. Regulatory Compliance: Designed to meet stringent regulatory standards, these machines help manufacturers comply with industry regulations.

Overview and Features

Vial filling machines are used for filling various types of vials, including those containing liquids, powders, and gels. They are particularly important in the pharmaceutical industry. Key features include:

1. Multi-Functionality: Capable of filling different vial sizes and types, including amber and clear vials.

2. Automatic Capping and Labeling: Many machines come equipped with systems for capping and labeling vials after filling.

3. Flexible Filling Systems: Can handle liquids, powders, and gels, making them versatile for different applications.

4. Inline Inspection: Some machines include inline inspection systems to check fill levels and detect defects.

The operation of a vial filling machine typically involves:

1. Vial Feeding: Vials are fed into the machine automatically or manually.

2. Filling: The machine dispenses the product into each vial with precision.

3. Capping: After filling, the vials are capped automatically.

4. Labeling: Finally, the vials may be labeled before packaging.

1. Precision and Reliability: High filling accuracy ensures that each vial meets specified volume requirements.

2. Reduced Contamination Risk: Automated systems minimize human contact, reducing the risk of contamination.

3. Scalability: Vial filling machines can be scaled up or down based on production needs.

4. Enhanced Quality Control: Inline inspection systems ensure product quality and consistency.

Overview and Features

Syrup filling machines are designed specifically for filling viscous liquids like syrups, sauces, and gels. They are commonly used in the food and beverage industry. Key features include:

1. Viscous Liquid Handling: Equipped with specialized pumps to handle thick liquids without damage.

2. Adjustable Fill Volumes: Many machines allow for quick adjustments to fill different bottle sizes and volumes.

3. Gravity or Pump Filling Systems: Depending on the product viscosity, machines can utilize gravity or pump systems for filling.

4. Capping Options: Automatic capping systems ensure that bottles are securely sealed after filling.

The operation of a syrup filling machine generally follows these steps:

1. Bottle Loading: Bottles are placed in the machine either manually or through a conveyor system.

2. Filling: The machine fills each bottle with syrup using either a gravity or pump system.

3. Capping: Bottles are capped automatically to ensure a tight seal.

4. Labeling and Packaging: After capping, bottles are labeled and prepared for shipping.

1. Consistent Filling: Ensures that each bottle is filled to the same level, maintaining product quality.

2. Efficiency: Automation speeds up production, making it ideal for high-volume operations.

3. Reduced Spillage: Advanced filling systems minimize spillage and product waste.

4. Flexibility: Machines can be easily adjusted for different syrup formulations and bottle sizes.

Filling machines, including tube, syringe, vial, and syrup filling machines, are indispensable tools in modern manufacturing. They enhance efficiency, accuracy, and product quality across various industries. By understanding their features, operational processes, and benefits, manufacturers can make informed decisions on which machines best suit their production needs. As technology advances, these machines continue to evolve, offering even greater capabilities and contributing to the ongoing improvements in manufacturing processes.