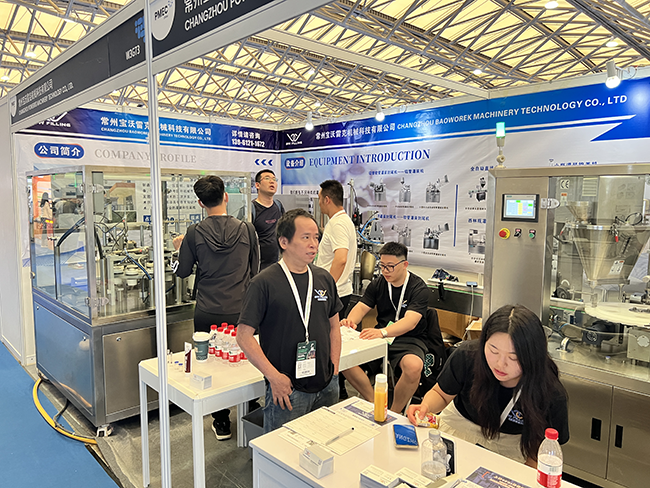

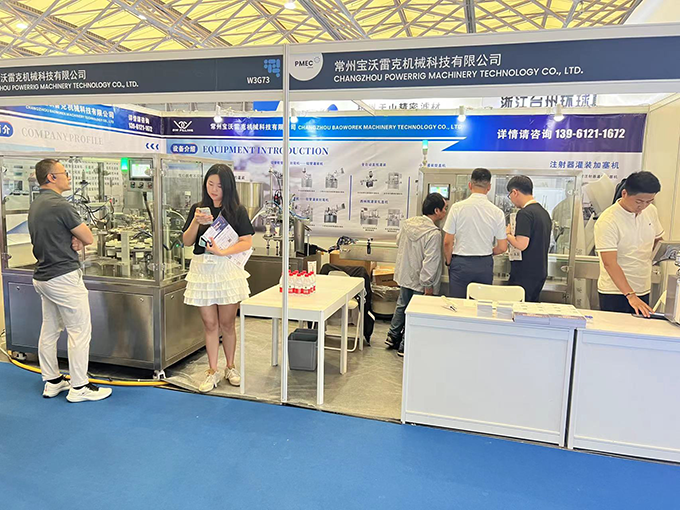

Shanghai CPHI Medical Equipment Exhibition: Showcasing Innovations in Pharmaceutical Machinery

The Shanghai CPHI Medical Equipment Exhibition is a premier event in the pharmaceutical and medical industry, attracting professionals, manufacturers, and innovators from around the globe. This year's exhibition promises to highlight groundbreaking advancements in medical technology and machinery, focusing on solutions that enhance production efficiency and product quality. We are excited to showcase our latest innovations, including tube filling machines, pharmaceutical filling machines, linear filling machines, and vial filling machines, designed to meet the evolving needs of the industry.

Our Key Products

At the CPHI exhibition, our company will present a comprehensive range of filling machines tailored for pharmaceutical applications. Here’s a closer look at our main products:

1. Tube Filling Machines Our tube filling machines are designed for precision and versatility, making them ideal for filling a wide variety of products, including creams, gels, and ointments. With features that allow for easy handling of different tube sizes and materials—such as plastic and aluminum—these machines ensure efficient production. Advanced automation technology minimizes the risk of human error while enhancing productivity. Equipped with automatic sealing and user-friendly interfaces, our tube filling machines streamline operations while maintaining the highest standards of quality.

2. Pharmaceutical Filling Machines In the pharmaceutical industry, accuracy and compliance are critical. Our pharmaceutical filling machines are engineered to meet stringent regulatory standards while providing precise dosing. Capable of filling various formulations—whether liquids, creams, or gels—these machines ensure consistent results and minimize product waste. The integration of cutting-edge technology helps maintain product integrity, making them essential for manufacturers focused on high-quality pharmaceutical products.

3. Linear Filling Machines Our linear filling machines offer high-speed and efficient filling capabilities, suitable for a diverse range of products. Their linear design optimizes production space and allows for quick changeovers between different formulations, making them ideal for facilities with varying production needs. These machines can handle liquids and viscous products with precision, contributing to overall operational efficiency.

4. Vial Filling Machines Designed for the high-speed filling of vials, our vial filling machines are perfect for products like serums, injectables, and essential oils. Featuring automated processes that enhance accuracy and reduce labor costs, these machines are particularly valuable for manufacturers focusing on small-batch, high-quality production. The ability to customize these machines for different vial sizes and types ensures versatility in various applications.

Why Attend the CPHI Exhibition?

Participating in the Shanghai CPHI Medical Equipment Exhibition offers numerous benefits for industry professionals. Here are some key advantages:

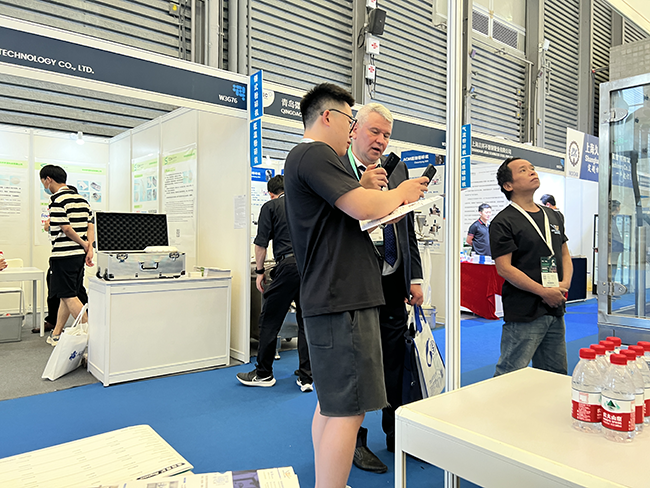

1. Networking Opportunities: Connect with industry leaders, suppliers, and potential clients to expand your professional network. Building relationships at the exhibition can lead to valuable collaborations and partnerships.

2. Discover Latest Innovations: Stay informed about the newest advancements in pharmaceutical machinery and medical technology. Understanding emerging trends can help businesses innovate and adapt to changing market demands.

3. Live Demonstrations: Experience firsthand demonstrations of our filling machines, showcasing their capabilities and efficiencies. Witnessing the machines in action allows attendees to evaluate their suitability for specific production requirements.

4. Educational Seminars: Attend informative seminars and workshops led by industry experts, covering critical topics such as regulatory compliance, production efficiency, and market insights. These sessions provide valuable knowledge to navigate challenges in the pharmaceutical sector.

5. Market Insights: Gain valuable market intelligence to inform your business strategies. Understanding the competitive landscape can help identify new opportunities for growth and development.

Article: Global Presence of Our Filling Machines

In today’s interconnected world, our company has successfully established a global presence, with our advanced filling machines being sold in numerous countries. Our commitment to quality and innovation has made us a trusted partner for manufacturers across various regions.

Key Markets

1. China As one of the largest markets for pharmaceutical and cosmetic products, our machines are widely used in China, where demand for high-quality production equipment is ever-growing.

2. United States In the U.S., our filling machines are favored by pharmaceutical and cosmetic manufacturers looking for reliability and precision in their production processes.

3. Germany and the United Kingdom These countries represent significant markets in Europe, where stringent quality standards drive the demand for our advanced filling solutions.

4. India and Brazil With booming pharmaceutical sectors, both India and Brazil have embraced our machines to meet their growing production needs.

5. Japan and South Korea Known for their technological advancements, these countries appreciate the efficiency and innovation of our machinery, making them key markets in Asia.

6. Italy and Canada Our machines are popular in these regions, where the focus on quality and craftsmanship aligns with our commitment to excellence.

7. Australia and Mexico As emerging markets, Australia and Mexico are increasingly adopting our filling machines to enhance their production capabilities.

8. Russia and Turkey These countries are experiencing growth in their pharmaceutical industries, and our machines are well-positioned to support their expanding needs.

9. Saudi Arabia and the United Arab Emirates With a strong focus on healthcare and pharmaceuticals, both nations have shown great interest in our reliable and efficient filling solutions.

10. Singapore and South Africa Our machines cater to the high standards of production expected in these markets, helping manufacturers achieve operational excellence.

11. Indonesia As a growing market in Southeast Asia, Indonesia is embracing modern technology, making our filling machines a valuable asset for local manufacturers.

Conclusion

Our commitment to providing high-quality filling machines has enabled us to successfully penetrate various global markets. By understanding the unique needs of each region, we continue to adapt and innovate, ensuring our machines meet the highest standards of performance and efficiency. Whether in Asia, Europe, the Americas, or the Middle East, our filling machines are helping manufacturers enhance their production processes and achieve their business goals.

The Shanghai CPHI Medical Equipment Exhibition serves as an essential platform for professionals in the pharmaceutical and medical industries. With our commitment to high-quality filling machines—such as tube filling machines, pharmaceutical filling machines, linear filling machines, and vial filling machines—we aim to help manufacturers optimize their production processes.

By participating in the exhibition, you can discover how our innovative solutions can elevate your business and meet the growing demands of the pharmaceutical market. Whether you are a manufacturer seeking to upgrade your equipment or a professional looking for insights into the latest trends, the CPHI exhibition is an event you won’t want to miss. Join us to explore the future of pharmaceutical machinery, where innovation meets quality and efficiency. Together, let’s set new standards in the industry and shape the next generation of medical products.

Exploring Filling Machines: Tube, Pharmaceutical, Vial, and Linear Filling Machines

In today's fast-paced manufacturing environment, filling machines play a vital role in streamlining production processes across various industries. From pharmaceuticals to cosmetics, these machines ensure accuracy, efficiency, and consistency in packaging. This article delves into four prominent types of filling machines: tube filling machines, pharmaceutical filling machines, vial filling machines, and linear filling machines. We will examine their uses, features, benefits, and operational processes.Tube Filling Machines

Tube filling machines are primarily used in the cosmetics, pharmaceutical, and food industries to fill and seal tubes with products such as creams, gels, ointments, and pastes. Their versatility allows them to accommodate a wide range of tube materials, including plastic, aluminum, and laminated tubes.

Features

1. Automation: Many tube filling machines are fully automated, reducing the need for manual labor and increasing production efficiency.

2. Precise Volume Control: Advanced filling systems ensure accurate and consistent filling volumes, minimizing product wastage.

3. Sealing Options: Various sealing methods, including ultrasonic sealing and crimping, ensure that tubes are securely closed.

4. Labeling Systems: Integrated labeling options streamline the packaging process by applying labels directly after filling and sealing.

1. Increased Production Speed: Automated processes significantly enhance the filling speed, allowing manufacturers to meet high-demand requirements.

2. Cost Efficiency: Reduced labor costs and minimized product wastage contribute to overall cost savings.

3. Improved Quality Control: High precision in filling reduces the likelihood of overfilling or underfilling, ensuring product consistency.

4. Extended Shelf Life: Proper sealing helps protect products from contamination and environmental factors, prolonging their shelf life.

Pharmaceutical filling machines are designed for filling containers with liquid or solid medications in compliance with strict regulatory standards. They are used in the production of injectable drugs, oral liquid medications, and powders. Their sterile and precise design is crucial in ensuring the safety and efficacy of pharmaceutical products.

Features

1. Aseptic Design: These machines are built to maintain sterile conditions, often featuring laminar flow hoods and cleanroom compatibility.

2. High Precision Dosing: Advanced metering systems allow for accurate dosage delivery, which is vital in pharmaceutical applications.

3. Multiple Container Compatibility: Pharmaceutical filling machines can accommodate various container types, including vials, syringes, and ampoules.

4. Automated Capping and Labeling: Many machines come with integrated systems for capping and labeling, enhancing overall production efficiency.

1. Regulatory Compliance: Designed to meet stringent pharmaceutical regulations, these machines help manufacturers ensure compliance with safety and quality standards.

2. Enhanced Sterility: Aseptic filling processes minimize the risk of contamination, ensuring product safety.

3. Increased Efficiency: Automation improves production speed and reduces labor costs, making it ideal for high-volume manufacturing.

4. Accurate Dosage Delivery: High precision in filling ensures that patients receive the correct dosage, enhancing therapeutic effectiveness.

1Vial filling machines are primarily used in the pharmaceutical and biotechnology industries for filling various types of vials with liquids, powders, and gels. They are essential for producing injectable medications and other sterile products.

Features

1. Multi-Functionality: These machines can handle different vial sizes and types, including amber, clear, and dark vials.

2. Flexible Filling Systems: They are equipped to fill both liquids and powders, making them versatile for various applications.

3. Automatic Capping and Labeling: Many vial filling machines come with integrated systems for capping and labeling, enhancing the production line.

4. Inline Inspection Systems: Some machines include inspection capabilities to verify fill levels and detect defects.

1. High Precision and Reliability: Accurate filling reduces the risk of underfilling or overfilling, ensuring consistent product quality.

2. Minimized Contamination Risk: Automated processes reduce human contact, which lowers the chances of contamination.

3. Scalability: Vial filling machines can be adjusted to meet varying production volumes, making them adaptable to different manufacturing needs.

4. Enhanced Quality Control: Inline inspection systems ensure that products meet quality standards before packaging.

Linear filling machines are widely used in various industries, including food and beverage, cosmetics, and pharmaceuticals. They are designed for high-speed filling of liquid products into containers such as bottles, jars, and pouches.

Features

1. High-Speed Production: Linear filling machines are capable of filling a large number of containers per minute, making them ideal for high-demand environments.

2. Accurate Filling Systems: They utilize volumetric or gravimetric filling methods to ensure precision in filling.

3. Flexible Configuration: These machines can be configured to fill different container sizes and shapes, providing versatility in production.

4. Integrated Capping and Labeling: Many linear filling machines come with automatic capping and labeling systems to streamline the production process.

1. Efficiency: The high-speed filling capabilities significantly reduce production time, increasing overall efficiency.

2. Cost-Effectiveness: Automation reduces labor costs and minimizes product wastage, contributing to cost savings.

3. Versatility: Linear filling machines can handle a variety of products and container types, making them suitable for different industries.

4. Enhanced Quality Assurance: Accurate filling processes help maintain product quality and consistency, reducing the likelihood of recalls.

Filling machines, including tube filling machines, pharmaceutical filling machines, vial filling machines, and linear filling machines, are indispensable in modern manufacturing. They enhance efficiency, accuracy, and product quality across diverse industries. By understanding the unique features, operational processes, and benefits of each type of filling machine, manufacturers can make informed decisions to optimize their production lines. As technology continues to advance, these machines will evolve, offering even greater capabilities and contributing to improved manufacturing processes worldwide.