- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

MIC Double Side Labeling Machine

Mic Machinery is committed to delivering high-quality labeling solutions for modern production lines. Our Double Side Labeling Machine provides precise, efficient, and reliable labeling for a wide range of bottles and containers, helping businesses enhance brand presentation and operational efficiency.

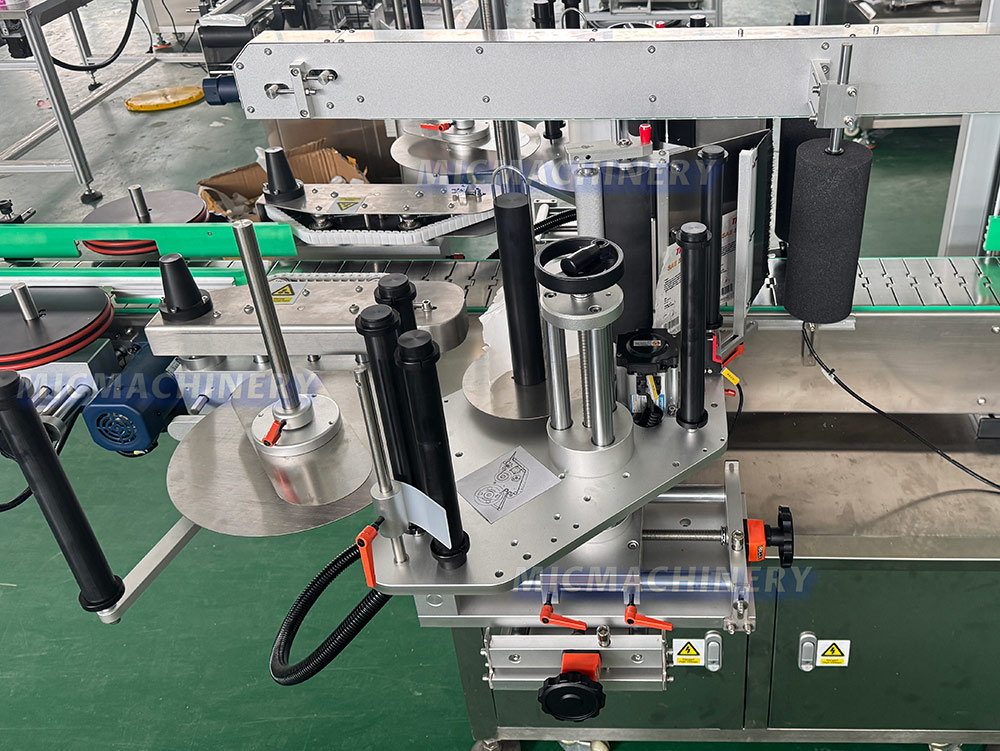

Labeling Worktable

The labeling worktable in a Double Side Labeling Machine provides a stable and adjustable platform for containers, ensuring precise label placement. Its ergonomic design allows smooth handling of bottles of various sizes, improving efficiency, reducing misalignment, and supporting high-speed, consistent labeling operations.

Conveyor Belt

The conveyor belt in a Double Side Labeling Machine ensures smooth and consistent movement of containers through the labeling process. Designed for stability and speed, it maintains accurate positioning, reduces downtime, and supports high-efficiency production, guaranteeing precise label application on every product.

Touch Screen Display

The touch screen display in a Double Side Labeling Machine provides intuitive control over all operations. Operators can easily adjust speed, monitor production status, and troubleshoot issues. Its user-friendly interface enhances efficiency, reduces errors, and ensures consistent, high-quality labeling for every container.

The Double Side Labeling Machine combines robust construction with advanced automation to ensure consistent performance. It is suitable for labeling round, square, and irregular-shaped containers in industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals. The machine’s design emphasizes durability, hygiene, and minimal maintenance, making it a long-term solution for high-speed production.

Our Double Side Labeller offers several advantages that make it a preferred choice:

● High Precision Labeling: Ensures labels are applied accurately on both sides of containers, reducing waste.

● Flexible Container Handling: Compatible with various bottle shapes and sizes.

● User-Friendly Interface: Smart control panel simplifies operation and monitoring.

● Durable Construction: Built with stainless steel and quality components for extended service life.

● Stable Operation: Maintains consistent labeling speed and alignment during high-volume production.

Applications Across Industries

The Double Side Labeling Machine is ideal for companies requiring versatile labeling solutions:

● Food & Beverage: Juices, sauces, oils, and bottled drinks.

● Pharmaceuticals & Cosmetics: Medicines, creams, shampoos, and lotions.

● Chemical & Household Products: Detergents, cleaners, and lubricants.

For businesses that only need one-sided labeling, our Single Side Sticker Labeling Machine provides an efficient alternative without compromising quality.

Why Choose Mic Machinery?

As experienced Double Side Labeller manufacturers, Mic Machinery provides more than machines—we offer complete labeling solutions:

● Customization Options: Tailored systems to fit unique production requirements.

● Technical Support: Comprehensive training, installation guidance, and after-sales service.

● Global Experience: Trusted by clients worldwide for reliable and innovative labeling equipment.

● Continuous Innovation: Our R&D team ensures our machines stay at the forefront of labeling technology.

Commitment to Quality

Every Double Side Labeling Machine reflects Mic Machinery’s dedication to precision and professionalism. By integrating cutting-edge technology and robust engineering, our machines help businesses increase productivity, reduce errors, and maintain a high-quality appearance for all packaged products.

Conclusion

For companies seeking reliable Double Side Labeller or Single Side Sticker Labeling Machine solutions, Mic Machinery is the trusted partner. Our professional expertise, durable equipment, and global support network ensure efficient, consistent, and high-quality labeling to meet diverse production demands.

|

Capacity |

20-160bottles/min |

|

Labeling Objects |

bottles,cans,jars,contons and cups efc. |

|

Label |

adhesive sticker |

|

Label Accuracy |

±1.0mm |

|

Label Roll |

φ76mm(innerdia,)

φ350mm(outer dia.)

|

|

Laber Size |

150-300mm width 15-300mm length |

|

Conveyor Speed |

≤40m/min |

|

Controller |

PLC touch screen |

|

Dimension L*W*H |

2300*1300*1500mm |

|

Weight |

230kg |