- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

MIC Double Side Labeller

The MIC Double Side Labeller from Mic Machinery represents advanced labeling technology designed to meet modern packaging demands. With precise labeling accuracy and stable operation, this labeling machine delivers efficient, high-quality performance suitable for a wide range of industries including food, beverage, cosmetics, and pharmaceuticals. Compact yet powerful, it ensures consistent labeling on both sides of containers with exceptional speed and reliability.

Conveyor

The conveyor in the MIC Double Side Labeller is engineered for smooth and precise bottle transport. It ensures accurate positioning and stable movement during the labeling process, perfectly synchronizing with the automatic bottle labeling machine to maintain high-speed, consistent performance.

Spring Pressing Mechanism

The spring pressing mechanism in the MIC Double Side Labeller ensures firm bottle stability during labeling. By applying balanced pressure, it prevents shaking or misalignment, allowing the automatic bottle labeling machine to achieve precise, wrinkle-free label application on both sides.

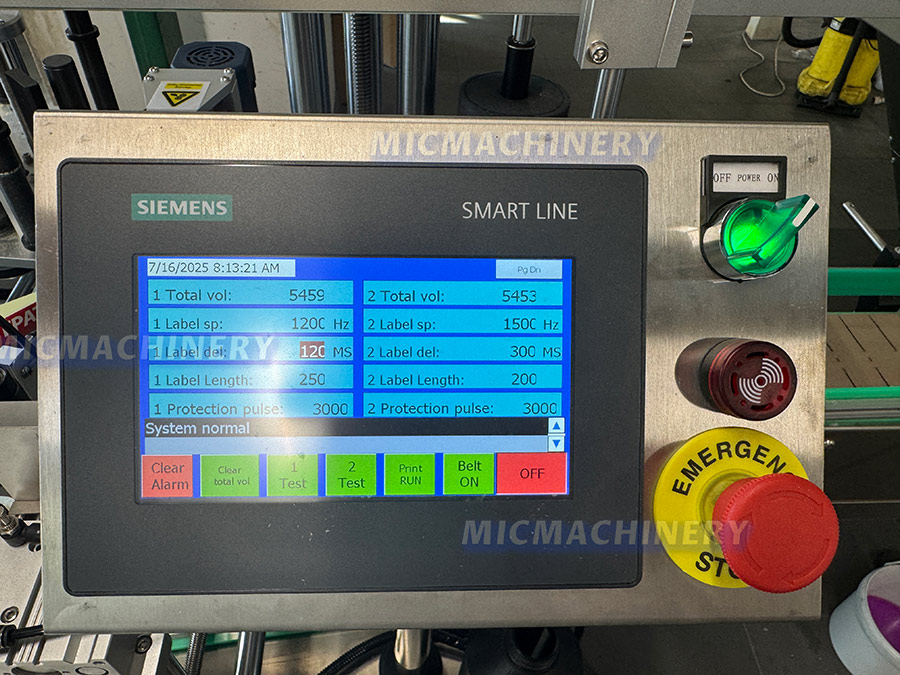

Touch Screen Display

The touch screen display in the MIC Double Side Labeller provides an intuitive control interface for operators. It allows easy adjustment of labeling parameters, real-time monitoring, and quick troubleshooting, ensuring the automatic bottle labeling machine runs efficiently and accurately

Precision and Efficiency in Labeling

As an automatic bottle labeling machine, the MIC Double Side Labeller guarantees seamless integration into production lines. Its robust design and high-precision sensor system ensure accurate label placement even at high speeds. Whether you’re labeling flat, round, or square bottles, the equipment adapts to varying shapes and materials with ease. The system’s servo-driven control and advanced PLC program make every labeling process smooth, efficient, and repeatable, ensuring consistent results across every product batch.

Main Features and Highlights

The MIC Double Side Labeller combines intelligent technology with mechanical stability to maximize performance.

Key highlights include:

1)Dual-Side Labeling Capability: Simultaneous labeling on both front and back surfaces of bottles, enhancing efficiency and product presentation.

2)Flexible Adjustment System: Easy to adjust for different bottle shapes and label sizes, minimizing downtime during product changeovers.

3)High-Precision Sensors: Equipped with optical sensors for detecting bottle position, preventing label misalignment or waste.

4)Touch Screen Control: User-friendly HMI interface allows operators to easily set parameters, monitor operation, and troubleshoot errors.

5)Durable Construction: Built with stainless steel and anodized aluminum for long service life and compliance with GMP standards.

Advanced Technology for Modern Production

The automatic bottle labeling machine is designed to integrate smoothly into automated production environments. It supports connection with upstream and downstream systems such as filling machines, capping machines, and conveyors.

Key technical strengths include:

● Servo Motor Drive: Provides stable label feeding, precise speed control, and smooth label application.

● Intelligent Detection: Automatically detects missing labels or bottles, ensuring error-free operation.

● Modular Design: Simplifies maintenance and allows quick replacement of components to minimize downtime.

● Energy Efficiency: Optimized motor control reduces power consumption while maintaining high throughput.

Versatility and Application Range

This labeling machine is ideal for industries requiring clean, professional label application. From beverage bottles and detergent containers to cosmetic jars and pharmaceutical packaging, it handles a wide range of bottle types with exceptional flexibility.

● Food & Beverage: Ensures brand consistency for juice, water, and condiment bottles.

● Cosmetics: Provides precise, bubble-free labeling on curved or irregular surfaces.

● Pharmaceutical & Chemical: Meets strict hygiene standards while ensuring accurate product identification.

Its versatility and reliable performance make the MIC Double Side Labeller a trusted choice for businesses seeking scalable labeling solutions.

Mic Machinery: Professionalism and Reliability

As a leading manufacturer of packaging and labeling machine solutions, Mic Machinery is committed to innovation, precision, and quality. Each automatic bottle labeling machine is designed with a deep understanding of customer needs and industry standards. Our engineering team ensures every model, including the MIC Double Side Labeller, delivers stable operation, long lifespan, and easy maintenance. By combining advanced automation with durable craftsmanship, Mic Machinery continues to serve global clients with professional and efficient labeling technology.

Conclusion

The MIC Double Side Labeller represents the perfect blend of technology, reliability, and professional design. Whether you need an efficient automatic bottle labeling machine or a robust labeling machine for dual-side applications, Mic Machinery provides tailored solutions that enhance productivity and product quality. It’s a modern investment for businesses aiming to achieve seamless labeling performance and long-term value.

|

Item |

Specification |

|

Label Object |

plastic bottle |

|

Power |

3.5Kw |

|

Production Speed |

20-60 bottles/Min |

|

Rated Voltage |

220V 1P 50HZ |

|

Working Air Pressure |

0.4-0.6Mpa |

|

Dimension (L*W*H) |

2800*1400*1650mm |