- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

MIC L30 Semi Automatic Tube Filler

At Mic Machinery, we provide advanced packaging solutions tailored to meet the needs of modern manufacturers. Our semi automatic tube filler is designed for efficiency, reliability, and precision, making it an excellent choice for companies looking to optimize production without compromising on quality.

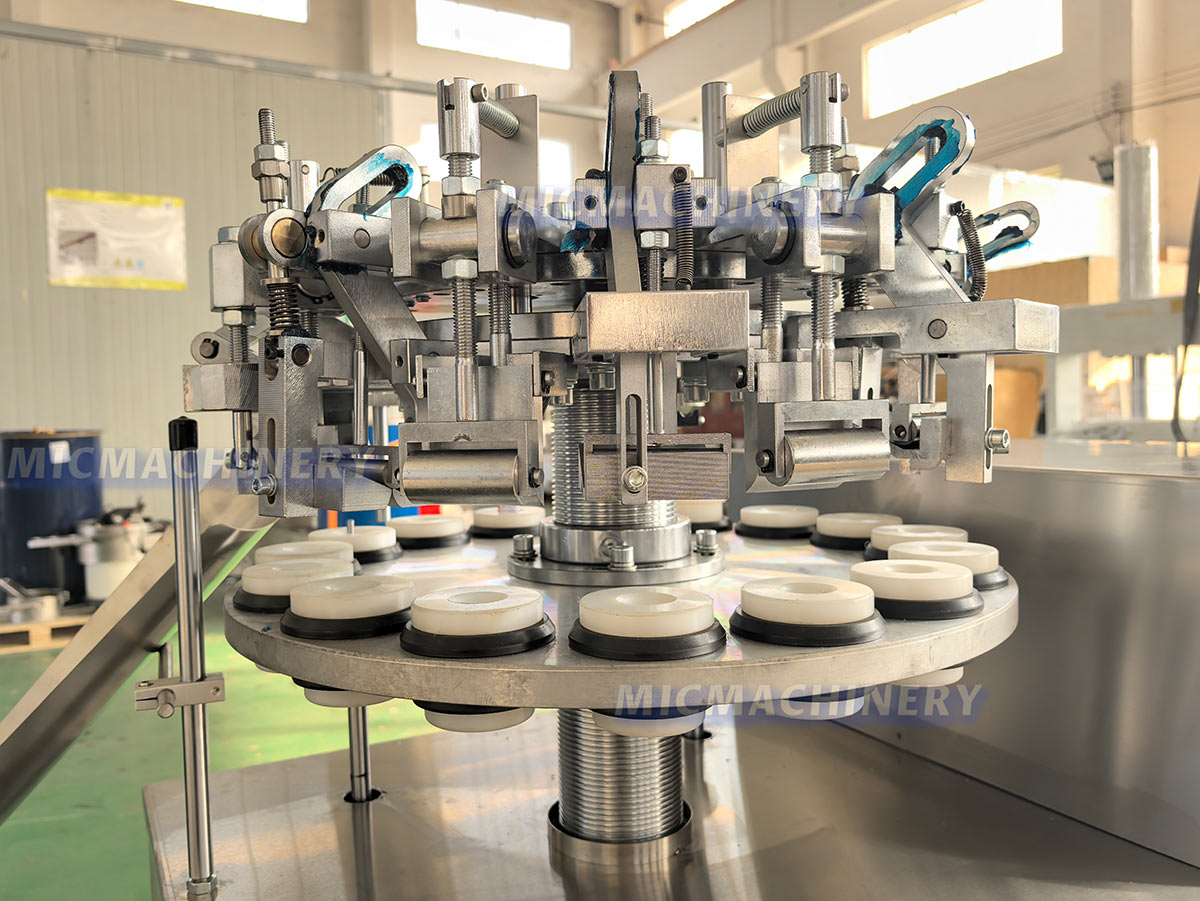

Main Platform

The main platform in a semi automatic tube filler is built for stability and precision, providing a secure base for accurate filling and sealing operations. Designed with durable materials, it supports smooth handling of various tubes, ensuring consistent results and long-term reliability in production.

Control Panel

The control panel of a semi automatic tube filler is designed for user-friendly operation, allowing operators to adjust filling volume, speed, and sealing temperature with precision. Its intuitive interface ensures efficient performance, minimizes errors, and supports consistent, high-quality tube filling.

Tube Exit Rail

The Tube Exit Rail in a semi-automatic tube filler ensures smooth and precise transfer of filled tubes from the rotating platform to the next stage. It guides aluminum or plastic tubes without tipping or damage, maintaining alignment and workflow efficiency, and supports consistent production quality.

Precision and Reliability in Tube Filling

The tube filler machine offered by Mic Machinery is engineered with state-of-the-art technology to ensure accurate dosing and consistent sealing. Whether you are working with creams, ointments, gels, or pastes, this system minimizes waste while maximizing output. Built with durable materials and user-friendly controls, it is an ideal choice for businesses seeking both efficiency and ease of operation.

Key Features of Our Semi Automatic Tube Filler

To give you a clearer view of the advantages, here are the main features:

● High filling accuracy with adjustable volume control.

● Versatile compatibility with plastic, laminate, and aluminum tubes.

● Compact design that saves space in production environments.

● Easy-to-use interface suitable for both beginners and experienced operators.

● Robust construction that ensures long service life.

With these strengths, our semi automatic tube filler helps streamline operations and improves overall production quality.

Benefits for Industrial Applications

Choosing the right tube filler machine is crucial for industries ranging from pharmaceuticals to cosmetics and food production. Here are some benefits our customers enjoy:

● Consistency and hygiene – reduces contamination risks.

● Flexible production – suitable for small to medium-scale businesses.

● Cost efficiency– minimizes material loss and lowers labor requirements.

● Adaptability – our systems work with both plastic and aluminium tube filling machine setups.

By integrating our equipment into your workflow, you can achieve reliable results while ensuring compliance with industry standards.

Why Choose Mic Machinery?

As a trusted manufacturer with years of expertise, Mic Machinery has established a reputation for delivering advanced packaging solutions worldwide. Our semi automatic tube filler is not just a piece of equipment—it’s a reflection of our commitment to innovation and customer satisfaction. Every machine undergoes strict quality control checks, ensuring it meets international safety and performance benchmarks. Furthermore, our technical team provides installation guidance, operator training, and after-sales support to maximize your investment.

Your Partner for Tube Filling Solutions

Whether you are seeking a tube filler machine for cosmetics, pharmaceuticals, or food industries, Mic Machinery has the right solution. From versatile models to specialized systems like the aluminium tube filling machine, we offer equipment that adapts to your specific production needs. By choosing us, you gain not only a reliable machine but also a long-term partner dedicated to helping your business grow.

|

Weight |

250kg |

|

Dimension |

1130*750*1680mm |

|

Power |

220v+1 |

|

Motor |

1.1Kw |

|

Working Temperature |

5-50℃ |

|

Compressed Air |

0.6-0.7Mpa |

|

Filling volume |

2-30ml/5-75ml/75-150ml(Customized) |

|

Quantity Error |

<2% |

|

Capacity |

10-50tube/min |

|

Parts |

Brand |

|

Machine Body Material

|

Stainless steel SUS 304 |

|

PLC |

Panasonic(Japan) |

|

Switch & Botton |

Schneider(France) |

|

Motor |

Qipeng(China) |

|

Variable-frequency Drive |

Xinjie(China) |

|

Cam Graduator |

Yuntong(China) |

|

Color Sensor |

Panasonic(Japan) |

|

Stepping |

East(Japan) |

- MIC Tube Filling Sealing Machine

- MIC Tube Filling Equipment

- MIC-R30 Semi Automatic Tube Filler (20-35 Tubes/min)

- MIC-R45 Automatic Tube Filler Machine

- MIC-L30 Semi Automatic Tube Filler

- MIC Tube Filling Machine Suppliers

- MIC Small Automatic Tube Filling Equipment

- MIC Small Fully Automatic Aluminum Tube Filling Machine

- MIC-R30I Manual Tube Filling Machine ( Cosmetic, Ointment, 20-30 Tubes/min )

- MIC-R45 Ointment Filling Machine ( Ointment, Cream, 30-35 Tubes/min )

- MIC-R60 Automatic Tube Filling Machine ( Lotion, Cream, Cosmetic, 30-65 Tubes/min )

- MIC-L45 Aluminum Tube Filling Machine ( Paste, Paint, Adhesive, 30-75 Tubes/min )

- MIC-L30 Tube Filling Machine ( Glue, Toothpaste, Paint, 10-50 Tubes/min )

- MIC-L60 Aluminium Tube Filling Machine ( Ointment, Toothpaste, Paste, 60-80 Tubes/min )