- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Mic Machinery proudly introduces the Small Fully Automatic Aluminum Tube Filling Machine, an advanced solution engineered to meet the demands of modern pharmaceutical, cosmetic, and chemical industries. This compact and efficient machine is designed for seamless performance in high-precision production environments, making it the preferred choice for companies seeking accuracy, speed, and reliability in tube packaging.

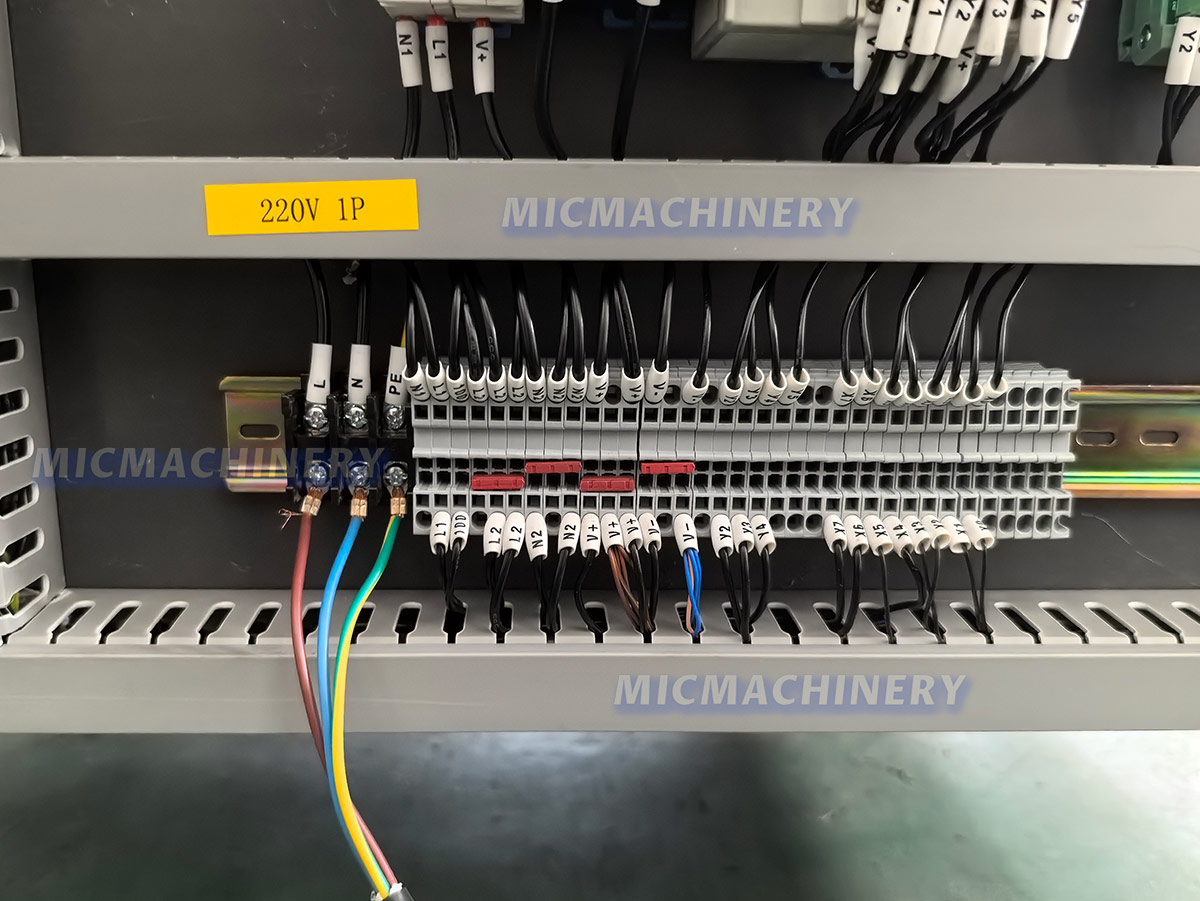

Control Panel

The control panel of the Aluminum Tube Filling Machine features a user-friendly touchscreen interface, allowing operators to easily set parameters, monitor operations, and perform diagnostics. Its intuitive design ensures efficient control, quick setup, and seamless adjustment of filling functions.

Double Hopper

The double hopper in the Aluminum Tube Filling Machine enables continuous and efficient filling by allowing two different products or larger batch volumes to be processed without interruption. It ensures smooth material flow, reduces downtime, and supports high-speed, dual-product filling operations.

Reliable and Compact Tube Filling Equipment for Modern Industry

Our tube filling equipment is specifically optimized for small-diameter aluminum tubes. With a user-friendly interface and precise automation, it can fill, seal, and eject tubes with minimal operator intervention. The fully enclosed stainless-steel frame not only ensures hygiene but also provides long-lasting durability even in demanding environments. Mic Machinery’s commitment to quality ensures that each component meets international safety and efficiency standards, delivering consistent and superior performance for years.

Key Features:

● Compact footprint ideal for limited space production lines

● PLC-controlled system with touch-screen interface

● High-speed rotary indexing table for efficient tube positioning

● Suitable for filling cream, gel, ointment, or paste materials

Advanced Tube Filling System with High Accuracy and Stability

This small aluminum tube filling system is built with cutting-edge servo control technology and a robust pneumatic system, ensuring consistent filling volumes and minimal waste. With high-precision metering pumps, the machine can handle a range of viscosities while maintaining perfect fill accuracy. Automatic tube orientation ensures alignment for branding and quality assurance.

System Highlights:

● Adjustable fill volume without mechanical changes

● Automatic detection of missing tubes and fill rejection

● Smooth operation and low maintenance design

By integrating all critical tube handling functions into one automated system, Mic Machinery reduces production time and labor costs while increasing output and consistency.

Flexible Applications Across Industries

Our tube filling machine is designed to adapt to a wide range of materials and applications, making it ideal for the pharmaceutical, cosmetic, food, and chemical sectors. Its ability to work with aluminum tubes of various diameters and lengths makes it a versatile solution for diverse packaging needs.

Applications Include:

● Medicinal creams and ointments

● Cosmetic pastes, such as facial cleansers and hair gels

● Industrial greases and adhesives

● Specialty food items like condiments and sauces

Whether you're a startup or a large-scale producer, this solution will streamline your tube packaging process with unmatched precision.

Why Choose Mic Machinery’s Tube Filling Solutions?

Mic Machinery has been at the forefront of automated packaging innovation for over a decade. Our tube filling machine solutions combine compact design, advanced automation, and strict compliance with GMP standards. As a professional tube packaging system manufacturer, we deliver products that are both user-oriented and performance-driven.

What Sets Us Apart?

● In-house engineering and custom design capabilities

● Exported to over 40 countries with excellent feedback

● Extensive testing and quality assurance before delivery

● Dedicated after-sales support and operator training

We understand that every production line is unique, which is why we offer tailored configurations to meet specific client requirements.

Easy Operation, Efficient Workflow, and Long-term Value

Our tube filling system is built for ease of use, from tube loading to sealing and discharge. Minimal training is needed to get operators up to speed, and the intuitive touchscreen interface provides real-time diagnostics and adjustment options. Cleaning and changeover are fast and simple, increasing uptime and reducing downtime.

Operational Benefits:

● Quick setup and tube size changeover

● Stable, vibration-free structure for continuous operation

● Digital controls for fill volume and sealing temperature

● Compact design with integrated safety features

This makes it an ideal choice for contract manufacturers and businesses aiming for high productivity in limited spaces.

Global Reach and Trusted Service from Mic Machinery

As a leading supplier of tube filling equipment and tube filling system solutions, Mic Machinery has a proven record of helping customers worldwide scale their production. From our state-of-the-art manufacturing base in China, we deliver high-quality machines to clients in Europe, North America, Southeast Asia, and the Middle East. Each machine is backed by our professional support team, available for remote diagnostics, spare parts service, and technical assistance.

Investing in our tube filling machine means more than just purchasing equipment—it means gaining a reliable partner in your production success.

|

Weight |

850Kg |

|

Dimension |

1950*800*1850mm |

|

Power |

220V/50Hz |

|

Motor |

2.2Kw |

|

Filling volume |

3-300ml(Customized) |

|

Capacity |

30-75 tubes/min |

|

Suitable Filling Material |

Aluminum tube |

|

Maximum Tube Dia. |

80mm |

|

Date Printed |

1-2 rows (numbers & letters) |

|

Additional Function |

Air Blow after filling |

|

Name |

Brand |

|

Framework |

SUS 304 Stainless Steel |

|

Touch Screen |

Simems |

|

Main Motor |

Taiwan, Mingbang |

|

PLC |

Siemems |

|

Stepping Motor |

Japan EAST |

|

Stepping Drive |

Japan EAST |

|

Color Mark Sensor |

Germany Sick |

|

Approch Switch |

Omron |

|

Media Relay |

Omron |

|

Heater Gun |

Switzerland Leister |

|

Magnetic Vavle |

Taiwan AIRTAC |

|

Protractor |

China, Shangdong |

|

Stirring Motor |

XiangGang EAST |

|

Pneumatic Elements |

Taiwan AIRTAC |

|

Pump for Filling |

Own Produce (MIC) |

|

Hopper (50L) |

SUS316 |

|

Bearings |

Japan NSK |

|

Buttoms |

Schneider |

- MIC Soft Tube Filling and Sealing Machine

- MIC Tube Filling Sealing Machine

- MIC Tube Filling Equipment

- MIC-R30 Semi Automatic Tube Filler (20-35 Tubes/min)

- MIC-R45 Automatic Tube Filler Machine

- MIC-L30 Semi Automatic Tube Filler

- MIC Tube Filling Machine Suppliers

- MIC Small Automatic Tube Filling Equipment

- MIC Small Fully Automatic Aluminum Tube Filling Machine

- MIC-R30I Manual Tube Filling Machine ( Cosmetic, Ointment, 20-30 Tubes/min )

- MIC-R45 Ointment Filling Machine ( Ointment, Cream, 30-35 Tubes/min )

- MIC-R60 Automatic Tube Filling Machine ( Lotion, Cream, Cosmetic, 30-65 Tubes/min )

- MIC-L45 Aluminum Tube Filling Machine ( Paste, Paint, Adhesive, 30-75 Tubes/min )

- MIC-L30 Tube Filling Machine ( Glue, Toothpaste, Paint, 10-50 Tubes/min )

- MIC-L60 Aluminium Tube Filling Machine ( Ointment, Toothpaste, Paste, 60-80 Tubes/min )