- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Overview

A pesticide syringe filling machine is an essential piece of equipment designed for the precise and efficient filling of syringes with pesticide formulations. This type of machine is crucial in agricultural and industrial sectors where accurate dosing and packaging of pesticides are required to ensure safety, effectiveness, and compliance with regulatory standards.

Performance

1. High Precision:

The pesticide syringe filling machine is engineered to deliver high precision in filling operations. Utilizing advanced metering systems, the machine ensures that each syringe is filled with the exact amount of pesticide, minimizing waste and ensuring consistent application.

2. Speed and Efficiency:

These machines are capable of high-speed filling, significantly increasing production rates. They are designed to handle large volumes, making them suitable for both small-scale and large-scale pesticide production facilities.

3. Versatility:

The machine can accommodate various syringe sizes and types, providing flexibility for different packaging needs. This versatility is essential for manufacturers dealing with multiple pesticide products or varying customer requirements.

4. Automated Operation:

Modern pesticide syringe filling machines come with fully automated systems that reduce the need for manual intervention. Features such as automatic syringe feeding, filling, and capping streamline the entire process, enhancing productivity and reducing labor costs.

5. Hygiene and Safety:

Ensuring the safety of operators and the integrity of the pesticide is paramount. These machines are constructed with materials that are resistant to corrosion and easy to clean, maintaining high hygiene standards. Additionally, they are equipped with safety mechanisms to prevent spills, leaks, and exposure to hazardous chemicals.

Key Features

1. Accurate Dosing:

The precise dosing mechanism of the pesticide filling machine ensures that each syringe contains the correct volume of pesticide, which is critical for effectiveness and regulatory compliance.

2. User-Friendly Interface:

Operators can easily manage and control the filling process through a user-friendly interface, typically featuring touchscreens and intuitive software. This ease of use reduces training time and operational errors.

3. Robust Construction:

Built with durable materials, the pesticide syringe filling machine is designed to withstand the harsh environments often found in industrial and agricultural settings. Its robust construction ensures long-term reliability and minimal downtime.

4. Customizable Settings:

Manufacturers can customize the machine settings to match specific product requirements, including fill volume, filling speed, and syringe type. This adaptability ensures that the machine meets diverse production needs.

5. Compliance with Standards:

These machines are designed to comply with industry standards and regulations, ensuring that the filled syringes meet all necessary safety and quality requirements.

Conclusion

Investing in a pesticide filling machine, also known as a pesticide filling machine or pesticide packing machine, provides numerous benefits for manufacturers. Its high precision, speed, and efficiency, combined with advanced automation and safety features, make it an indispensable tool in the pesticide production industry. By ensuring accurate dosing and high hygiene standards, this machine helps manufacturers produce high-quality pesticide products that meet regulatory standards and satisfy customer needs.

The main platform

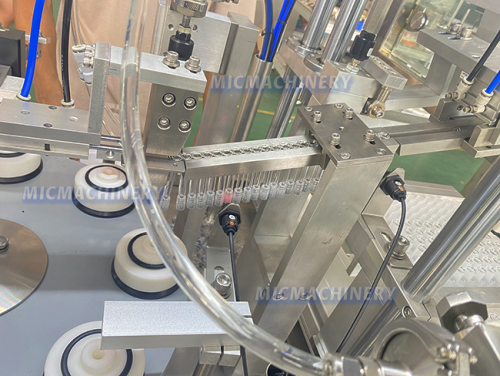

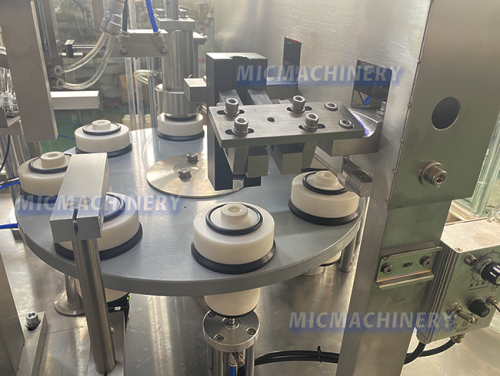

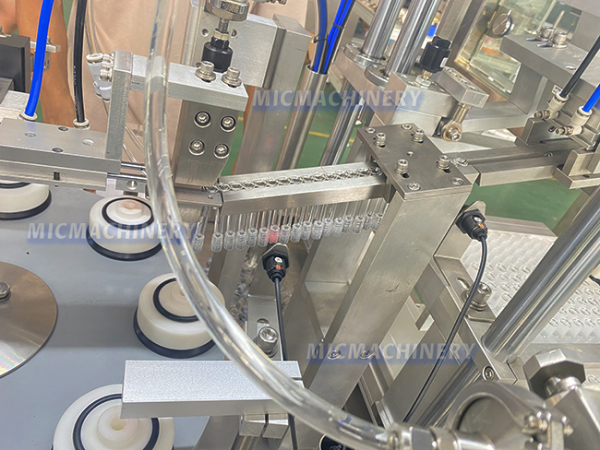

The picture includes mould, filling head,and automatic inside plug loading and pressplug stations.They are clear function and easy to clean.

Among them, the mould is used to fix the filling container and drive the container to move to the filling、capping and other stations. The circular design can save space while setting up multiple positions, so that the filling process is time-saving and efficient.

We can customize this mould, filling head, and so on

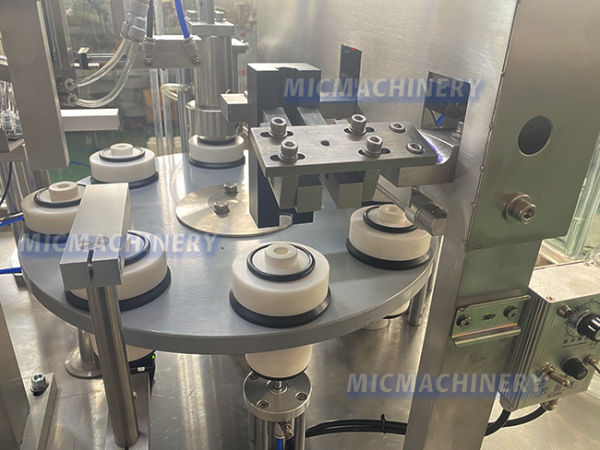

Inside plug loading automatically

Inside plug feeding cage with vibrating disk is connected to a pipe that carries the Inside plug ,They automatically arranges the Inside plug and deliver the Inside plug.

In this way, the syringe is covered in a consistent process, reducing the manual contact with the syringe process, and ensuring syringe hygiene,At the same time, labor costs are reduced

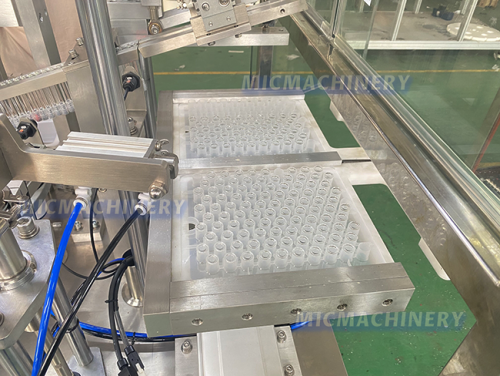

syringe auto loading system

When the syringes are lined up, the device will automatically load the syringes, which is very efficient to send the syringes to the location of the mold, the whole process is consistent and saves time

|

Syringe Filling Machine |

||||

|

model |

SGJ |

SGJ-1 |

SGJ-2 |

SGJ-3 |

|

application |

medicine, chemistry, biology,etc |

|||

|

Packing type |

various syringes, boosters, injection tubes,etc |

|||

|

speed |

5000pcs/h |

20-30pcs/min |

800-1000pcs/h |

800-1000pcs/h |

|

Filling arrange |

0.5-50ML |

5-100ML |

0.5-50ML |

0.5-50ML |

|

power |

3.5KW |

2KW |

2KW |

2KW |

|

size |

2500*1350*1600mm |

1380*1030*1800mm |

1800*800*1700mm |

1800*800*1700mm |

|

weight |

1500KG |

390KG |

450KG |

450KG |

In addition to,If you're looking for syringe filling machine,pre filled syringe filling machine manufacturers,syringe filling equipment,pfs filling machine,automatic syringe filler,syringe filling machine manufacturer,automatic syringe filling machine,syringe filling machine manufacturers,prefilled syringe filling machine,prefilled syringe machine,oral syringe filling machine,aseptic syringe filling equipment,sterile syringe filling machine,prefilled syringe machine manufacturers,syringe filling machine price.You can browse our product website more.

If you are more than interested in the machine ,you can contact us at market@micmachinery.com

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.