- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

Product Characteristics:

The Bleach Filling Machine boasts exceptional characteristics meticulously engineered for efficiency and precision. Crafted from robust materials, often featuring corrosion-resistant components, it ensures durability while meeting the stringent standards of the cleaning and disinfectant industry. Automated filling, precise dispensing, and sealing mechanisms define this machine, embodying the epitome of speed and accuracy in bleach packaging. Equipped with intuitive interfaces featuring advanced programmable controls, it seamlessly adapts to various container sizes and bleach viscosities. Anti-drip features and customizable settings preserve the quality of bleach formulations, delivering products that resonate with both efficiency and the promise of superior cleaning performance.

Product Applications:

The Bleach Filling Machine finds indispensable applications in the cleaning and sanitation sector, offering a streamlined solution for efficient bleach filling. Whether producing household bleach, industrial-strength disinfectants, or specialized bleach compounds, this machine ensures uniformity in dosage and presentation. Its adaptability caters to the dynamic requirements of the cleaning industry where each bleach variant demands a precise approach to dispensing, sealing, and preserving its unique properties. From large-scale industrial cleaning operations to smaller household cleaning product manufacturers, the Bleach Filling Machine plays a crucial role in delivering potent and effective bleach solutions.

Mechanical Principle:

At its core, the Bleach Filling Machine operates on advanced mechanical principles meticulously designed for precision, speed, and reliability. Employing cutting-edge volumetric or gravimetric filling systems, specialized nozzles, and sealing mechanisms, the machine precisely measures and dispenses the specified quantity of bleach formulations into individual containers. Fully automated sealing guarantees a secure, consistent, and air-tight closure, preserving the potency and integrity of the bleach product. Integrated sensors and programmable logic controllers (PLCs) oversee the entire process, ensuring seamless uniformity, minimizing errors, and enhancing the overall efficiency of bleach filling operations.

In conclusion, the Bleach Filling Machine stands as a pivotal player in the cleaning and disinfectant industry, ensuring the efficient and accurate packaging of essential bleach formulations. Its exceptional product characteristics, diverse applications, and advanced mechanical principles make it an indispensable asset for manufacturers globally. As a fundamental component in the production workflows of cleaning solutions, this machine continues to redefine the way bleach products are filled, ensuring each container embodies the essence of precision and the promise of superior cleaning and disinfecting performance in various applications.

Filling head

This machine is specially designed for filling corrosive liquids. All parts in contact with the liquid are made of antiseptic materials.

Main work process: When the bottle is under the filling head, the internal system controls the anti-corrosion filling head to move down, precise filling, no bottle no filling, special design can achieve no bubble filling.

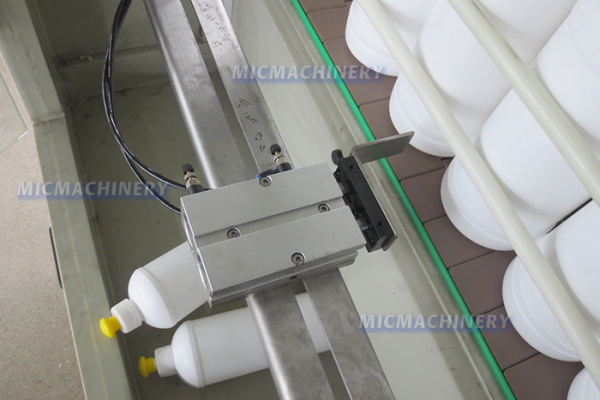

Bottle block air cylinder

When the bottle can reach a certain number, there is a special infrared sensor on the bottle track to receive the induction, and then automatically stuck behind the bottle, in front of the bottle after the bottle filling, and then let the behind the bottle to fill the vacancy, so as to achieve no bottle no filling

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of bottle,The width between the two pipes can be adjusted according to your container,ensure smooth bottle safely from the conveyor belt moved .

On the side of the conveyor is equipped with sensors that can automatically identify when the bottle to go out or, in order to send signals to filling station of screw cap

pesticides, chemicals, bottled agent type liquid dispensing, bottle filling, Applicable to a variety of different types of containers.

This machine function is:

1. This machine combines optical, mechanical, electrical, gas in one machine.

2. Adopt through control filling time to reach different volume filling.

3. Filling time can be precisely controlled to a hundredth of a second.

4. The filling process is completed under the PLC program control on the touch screen.

5. Having a stable and reliable operation, high efficiency, adaptability, the filling volume of measurement specification can be changed within a few minutes.

6. Filling valve use imported brands, advanced technology, sophisticated, non-drip filling phenomenon.

7. All parts frame, conveyor ,valve ,filling nozzle use anti-corrosion material.

8. Can customize vacuum or diving filling avoid have foma when filling.

This machine is our MIC automatic inline straight line normal pressure filling machine, can Prevent corrosion.

It can be used with capping machine, labeling machine supporting the formation of the production line.

This machine is guaranteed for one year and you can extent your guarantee easily by discuss with our sales.

Which you might be interested, under guaranteed, machine parts got broken by daily use, we will replace it once we are informed by free DHL.

|

Filling Heads |

12 heads |

|

Min Filling Volume |

500ml-5000ml |

|

Production Speed |

2000 Bph(basis on 5L bottle) 3000-5000Bph (basis on 1L) |

|

Voltage |

220V/380V |

|

Power |

1 kw |

|

Application Bottle Type |

1-5L different shape bottles |

|

Filling Error |

≤±0.5% |

|

Work Pressure |

0.55Mpa-0.65Mpa |

|

Size |

2000mm × 1000mm× 2200mm |

|

Weight |

700 kg |

|

Name |

Brand |

|

Touch Screen |

Canada Xinjie |

|

PLC |

Schneider France |

|

Frequency Conversion |

Schneider France |

|

Pneumatic Valve |

UAA USA |

|

The Electromagnetic Valve |

AirTac Taiwan |

|

Air Cylinder |

AirTac Taiwan |

|

Air Source |

AirTac Taiwan |

|

Photovoltaic Systems |

OPTEX Japan |

|

Differential Pressure Switch |

Johnson USA |

|

Switching Power Supply |

Mean Well Taiwan |

|

Machine Frame Material |

Use PVC Polypropylene material make, the material of our machine’s tank is Acid and alkali corrosion resistant material can resistant Acid and alkali and corrosion. |

- MIC Pesticide Filling Machine ( Pesticides, Disinfectants, Medical Alcohol, 2000-5000 Bottles/h )

- MIC-ZF12 Bleach Filling Machine ( Bleach, Pesticides, Disinfectants, 2000-5000 Bottles/h )

- MIC-ZF16 Pesticide Bottle Filling Machine (Oil, Sauce, Pesticide)

- MIC Pesticide Syringe Filling Machine (Pesticide, Medical 800-1500 Syringes/h)

- MIC Pesticide Packing Machine ( Pesticide, Liquid, 10-50 Bags/min )

- MIC Pesticide Packing Machine ( Honey, Ketchup, Sauce, 20-40 Sachets/min )