- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Overview

The small bottle paint filling machine is an advanced piece of equipment designed to cater to the needs of the paint industry. This machine is engineered to provide precise and efficient filling solutions for small bottles, ensuring optimal performance and high productivity.

Machine Performance

Accuracy and Precision: The small bottle paint filling machine boasts exceptional accuracy and precision. It is equipped with advanced sensors and control systems that guarantee each bottle is filled to the exact specified volume. This precision minimizes wastage and ensures consistent product quality.

Speed and Efficiency: With its high-speed filling capabilities, the paint filling machine significantly boosts production rates. It can fill a large number of bottles per minute, making it an ideal choice for businesses looking to scale up their operations without compromising on quality.

Versatility: This machine is compatible with various types of paint, including water-based, oil-based, and solvent-based paints. Its versatility makes it suitable for a wide range of paint filling applications.

Ease of Use: The paint filling machine is designed with user-friendly features, including an intuitive control panel and easy-to-follow instructions. Operators can quickly learn to operate the machine, reducing downtime and increasing productivity.

Durability and Reliability: Built with high-quality materials and components, the paint packing machine is durable and reliable. It can withstand the rigors of daily use in industrial environments, ensuring long-term performance and minimal maintenance requirements.

Key Features

Automatic Filling: The machine is fully automated, allowing for continuous filling operations with minimal human intervention. This automation enhances efficiency and reduces labor costs.

Adjustable Filling Volume: The paint filling equipment allows for easy adjustment of filling volumes, accommodating different bottle sizes and filling requirements.

Anti-drip System: Equipped with an anti-drip system, the machine prevents paint spills and ensures a clean and efficient filling process.

Compact Design: The compact design of the paint packing machine saves valuable floor space, making it suitable for small and large production facilities alike.

The paint filling equipment is ideal for various applications within the paint industry. It is commonly used for filling:

Decorative Paints: Ensuring accurate and consistent filling of small bottles for retail sales.

Industrial Paints: Efficiently handling high-viscosity industrial paints used in manufacturing and construction.

Specialty Paints: Filling specialty paints such as metallics, varnishes, and primers with precision.

Investing in a small bottle paint filling machine is a strategic decision for any paint manufacturer aiming to enhance their production capabilities. With its superior performance, ease of use, and reliability, this paint filling machine ensures high-quality filling operations, meeting the demands of both small and large-scale production environments. Whether you are looking for a paint packing machine or versatile paint filling equipment, this machine delivers exceptional results, making it a valuable addition to your production line.

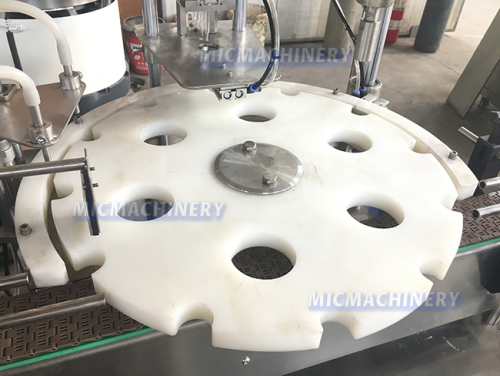

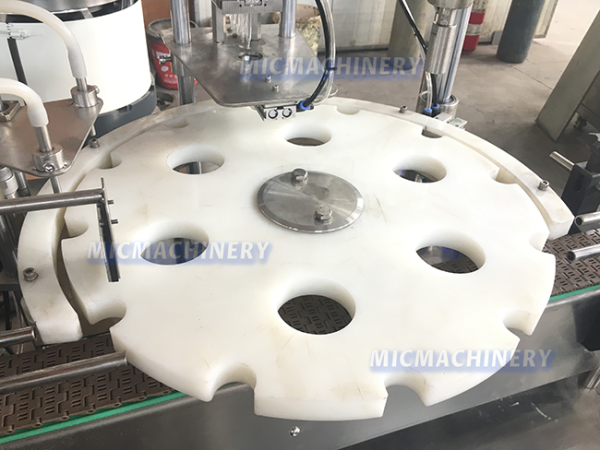

The main platform

The picture includes chuck, filling head,and automatic lid feeding and lid tightening stations.They are clear function and easy to clean.

Among them, the chuck is used to fix the filling container and drive the container to move to the filling、capping and other stations. The circular design can save space while setting up multiple positions, so that the filling process is time-saving and efficient

We can customize this turntable, filling head, screw cap and so on

Filling head

When the bottle through the conveyor belt was sent to the location of the chuck, automatic identification of sensors, control by internal program to send signals for filling station, when the bottle comes under the filling head, cylinder head began to move down the drive filling, filling process without dripping, do not waste material, also can ensure the bottle clean and tidy, convenient after labeling.

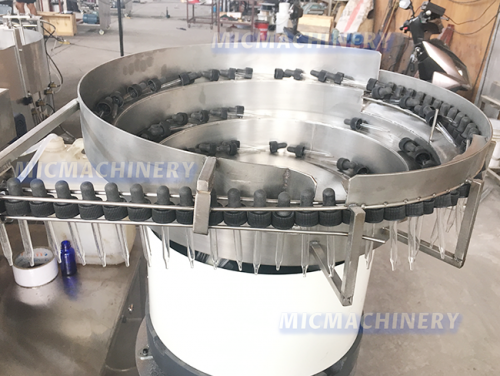

Automatic sorting device for the lid

Its main role is going to filling the bottle, hand put the bottle to the machine, open the bottle on the button on the touch screen, start automatically on the bottle, the bottle to the filling machine by the conveyor belt This process greatly save labor costs, and its work efficiency is very high, save time and effort.

Panit, E-liquid ,essential oil , VG PG seed oil into various round bottles with the filling range from 5-50 ml.

High precision cam provides a regular plate to position, cork and cap; accelerating cam makes capping heads going up and down ;constant turning arm screws caps; Peristaltic pump measures filling volume; and touch screen controls all action. No bottle no filling and no capping. The machine with advantage of high position .

Main Features Of MIC-L40 small bottle paint filling machine

1. Microcomputer setting, high filling accuracy

2. The main engine is equipped with stepless frequency speed control.

3. Automatic production capacity quantitative control.

4. With all kinds of fault alerting, for low pressure, no filling, no inner cap etc.

5. The machine can stop automatically in case of no filling, no inner cap etc.

If you want to know more models of filling machine, you can refer to the table below:

|

Vial Filling Machine |

||||||||

|

model |

FC-30 |

FC-X40 |

FC-P35 |

FC-P40 |

FC-T30 |

FC-N25 |

FC-E35 |

FC-Z40 |

|

application |

cosmetics, daily chemical and pharmaceutical industries such as nail polish, e-liquid, eye drop,etc |

|||||||

|

Packing type |

various round and flat glass and plastic bottles,etc |

|||||||

|

speed |

23-30 pcs/min |

30-50 pcs/min |

30-40 pcs/min |

25-30 pcs/min |

20-30 pcs/min |

15-25 pcs/min |

30-40 pcs/min |

30-50 pcs/min |

|

Filling arrange |

50-250ML |

10-100 ML |

10-100 ML |

10-100 ML |

30-120 ML |

2-30 ML |

10-100 ML |

20-150 ML |

|

power |

5kw |

2KW |

2KW |

5KW |

2KW |

2KW |

2KW |

2KW |

|

size |

2000*1000*1700mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

2000*1000*1500mm |

|

weight |

650KG |

550KG |

650KG |

650KG |

650KG |

650KG |

650KG |

600KG |

in short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Filling Volume |

5-50ml |

|

Capacity |

30-40bottles/hour |

|

Filling Precision |

≤±1% |

|

Power Supply |

380V/50Hz (Can customize) |

|

Capping Rate |

≥99% |

|

Stoppering Rate |

≥99% |

|

Air Supply |

1.3 m3/h 0.4-0.8Mpa |

|

Power |

2.0Kw |

|

Weight |

| Name |

Brand |

|

Button |

Schneider |

|

AC Conta ctor |

Schneider |

| Relay |

Schneider |

|

Frequency Transformer |

Taian |

|

Motor |

Qi peng |

| Air Cylinder |

AIR TAC |

| The electromagnatic valve |

AIR TAC |

|

Bearing |

NSK |

| PLC |

Schneider |

| Touch Screen |

Schneider |

| Photoelectric Detection | Sick |

- MIC-L30 Semi Automatic Paint Filling Machine (Speed 25-45 Tubs/m)

- MIC-R30 Paint Filling Machine (Speed 20-30 Tubes/m)

- MIC-L60 Paint Filling Machine (Speed 30-75 Tubes/m)

- MIC-ZF4 Paint Packing Machine (Speed 300 Barrels/h)

- MIC-XG2 2 Heads Paint Filling Machine (600-1200 Bottles/h)

- MIC Small Bottle Paint Filling Machine (Paint, Essential oil, 30-40 Bottles/min)