- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Description:

Efficiently fill paint containers with various viscosities using our state-of-the-art semi-automatic machine. With intuitive operation and precise control over filling volumes, our equipment minimizes product wastage and maximizes throughput, meeting the demands of high-volume production.

Our Semi-Automatic Tube Filling Machine offers seamless integration into your production line. Its user-friendly interface and customizable settings provide flexibility to adapt to different paint filling requirements, ensuring consistent and accurate results with every fill.

Boost productivity and reduce downtime with the reliability of our Semi-Automatic Tube Filling Machine. Built for continuous operation, this robust equipment delivers consistent output and superior product quality, meeting the highest industry standards.

Invest in precision-driven semi-automatic paint filling with our Semi-Automatic Tube Filling Machine, also known as a Paint Filling Machine or paint filling equipment. Stay ahead of the competition and meet the demands of today's market effortlessly. Contact us now to discover how this advanced solution can revolutionize your paint filling process.

This machine is mainly used for aluminum tube filling and sealing.

It has been widely used in the fields of Pharmacy, cosmetic, food and chemical etc.

This machine function is:

1. Manual tube loading

2. Cam cylinder system-Diving filling with tube base up (Fully filling from tube bottom to head)

3. Air-blow cutting after each filling (Design for high viscosity material like paint, silicone etc.)

4. Nitrogen dosing filling device (Insulate material from air)

5. Automatic benchmarking (Cursor positioning)

6 Automatic tube filling sealing & No tube no filling

7. Automatic tube folding sealing

8. Material hopper can heating and stirring

9. Automatic printing the batch dates code

10. Can update with European accessories like Siemens, Omron and Schneider etc.

-Machine design using your actual sample tubes and material, we support tube testing before payment

-The machine has CE certification, comply with GMP hygiene standard.

-We provide full-lifetime warranty with one year free accessories

The control panel

The control panel on the filling machine is the core of the machine, the function is clear, the operation is simple, as long as adjust the corresponding button, the internal program will control the machine to run smoothly

The main platform

The picture includes turntable, filling head,sensor,automatic flattened, fold-tube, date-printed stations.This is clear function and easy to clean.

Main workflow: automatically goes on the tube. When the tube comes, the sensor automatically identifies it, sends a signal to the filling station, and starts the filling.After the filling, the tail of the pipe is flattened, folded, folded forward and back, date printed, and finally the pipe is topped out.

We can customize this turntable, filling head, and so on

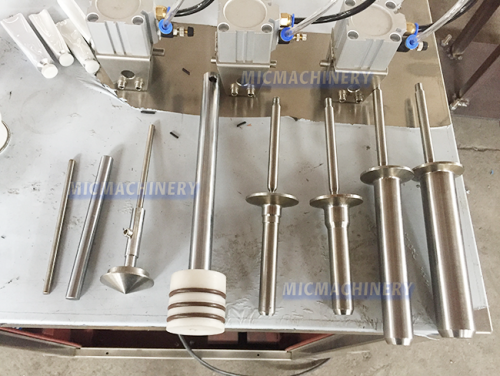

Sensor and Sensor rod

Main role is to sense the tube, and automatically turn the tube to ensure the standard.

Workflow: When the tube enters the machine bench, the sensor is automatic, adjusts the position of the pipe, and sends a signal to the next filling station. The internal program controls automatic filling

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

L30 |

L30I |

L45 |

L45I |

L60 |

L60I |

R30 |

R30I |

R45 |

R60 |

|

Application |

Pharmacy, cosmetic, food and chemical ,super glue, glue 502. etc. |

|||||||||

|

Packing Type |

Soft tube,aluminum tube,plastic tube. Etc |

|||||||||

|

Speed |

10-50 t/m |

25-45 t/m |

30-75 t/m |

40-45 t/m |

50-60 t/m |

50-60 t/m |

20-30 t/m |

20-30 t/m |

30-35 t/m |

30-65 t/m |

|

Filling Arrange |

1-300ml,2-300ml,3-20ml,5-75ml, 15-75ml, 75-250ml,5-75ml/75-150ml /150-300ml |

|||||||||

|

Power |

1.1Kw |

1.1kw |

2.2Kw |

2.2Kw |

2.2Kw |

2.2Kw |

1.1kw |

1.1Kw |

4KW |

5.5Kw |

|

Size |

1130*750*1680 mm |

1500*700*1800 mm |

1950*800*1850 mm |

1950*800*1850 mm |

1900*1400*2000 mm |

1900*1400*2000 mm |

1230*700*1400 mm

|

1230*700*1400 mm |

1450*1050*1750 mm |

1850*950*1980 mm |

|

Weight |

250Kg |

300Kg |

850Kg |

800 Kg |

850Kg |

1200 Kg |

250Kg |

250Kg |

475Kg |

850Kg |

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback:

|

Voltage |

110V/220V/380V |

|

Power |

1.1kw |

|

Air Pressure |

0.6-0.8Mpa |

|

Production Capacity |

25-45 tubes/min |

|

Filling Volume |

1-300ml |

|

Filling Error |

±0.5g |

|

Material |

SS304/316 |

|

Dimensions |

1500*700*1800mm |

|

Weight |

300KG |

| Parts | Brand |

|

Main Motor |

Wu XI Qi Peng |

|

PLC |

Panasonic JAPAN |

|

Stepping Motor |

East Japan |

|

Stepping Drive |

East Japan |

|

Sensor |

Germany Sick |

|

Approach Switch |

BFNFC |

|

Intermediate Relay |

Schneider |

|

Electromagnetic Valve |

Si Mai Ge |

|

Encoder |

Omron |

|

Mixing Motor (Optional) |

XiangGang Ease |

|

Air Cylinder |

Si Mai Ge |

|

Bearing |

Nsk |

|

Button |

Schneider |

|

Air Switch |

CHNT |

|

Power Switch |

Omron |

|

Temperature Control |

HuoYU |

- MIC-L30 Semi Automatic Paint Filling Machine (Speed 25-45 Tubs/m)

- MIC-R30 Paint Filling Machine (Speed 20-30 Tubes/m)

- MIC-L60 Paint Filling Machine (Speed 30-75 Tubes/m)

- MIC-ZF4 Paint Packing Machine (Speed 300 Barrels/h)

- MIC-XG2 2 Heads Paint Filling Machine (600-1200 Bottles/h)

- MIC Small Bottle Paint Filling Machine (Paint, Essential oil, 30-40 Bottles/min)