- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

At Mic Machinery, we specialize in advanced pouch packaging solutions tailored to the needs of modern production lines. Our Spout Pouch Packing Machine is designed with efficiency, flexibility, and precision in mind, making it the perfect choice for businesses across the food, beverage, cosmetic, and chemical industries.

Capping Part

The capping part in a Spout Pouch Filling Machine ensures each pouch is securely sealed after filling. Designed for accuracy and speed, it automatically aligns and tightens caps, preventing leaks and contamination while maintaining product freshness and consistent packaging quality.

Filling Head

The filling head in a Spout Pouch Filling Machine is engineered for precise and hygienic product dispensing. It controls flow accurately to reduce waste, prevent spillage, and maintain consistency. Built with food-grade materials, it ensures smooth operation for liquids, pastes, and semi-liquids.

Transmission Line

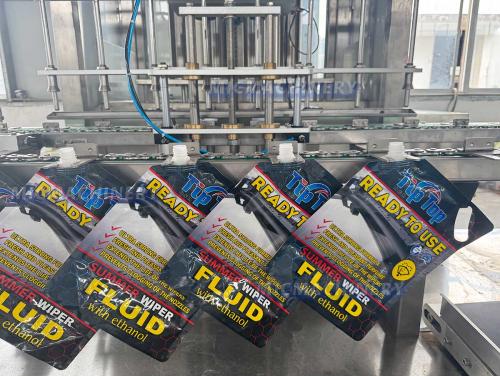

The transmission line in a Spout Pouch Filling Machine efficiently moves pouches through each stage of filling and capping. Engineered for smooth, stable operation, it ensures precise positioning, reduces downtime, and maintains consistent production speed, supporting high-efficiency and reliable packaging.

Professional Design and Performance

The Spout Pouch Packing Machine from Mic Machinery combines high-speed operation with outstanding accuracy. Built from durable stainless steel and equipped with advanced automation technology, it ensures a hygienic, reliable, and safe packaging process. This machine is suitable for a wide range of liquid and semi-liquid products such as juices, sauces, detergents, and personal care items. Its robust design allows continuous operation while maintaining consistency and minimizing downtime.

Key Features of Our Machine

To highlight its competitive advantages, our Spout Pouch Filling Machine includes the following features:

● Flexible Applications: Capable of handling different pouch sizes and spout types, supporting customized packaging requirements.

● Precision Filling System: Accurate volume control to reduce waste and guarantee product quality.

● User-Friendly Interface: Smart control panel for easy operation, monitoring, and troubleshooting.● Hygienic Standards: Built with food-grade materials and equipped with cleaning functions to ensure compliance with international standards.

● Durable and Stable: Designed to provide long service life with minimal maintenance.

Applications Across Industries

Our Spout Pouch Filling Machine is highly versatile, making it the ideal choice for companies in:

● Food and Beverage: Juices, yogurt drinks, sauces, edible oils, and more.

● Cosmetics and Personal Care: Shampoo, conditioner, creams, and lotions.

● Household and Industrial Products: Detergents, cleaners, motor oils, and lubricants.

This wide application range demonstrates Mic Machinery’s ability to deliver equipment that adapts to evolving market needs.

Why Choose Mic Machinery?

As one of the trusted Spout Pouch Filling Machine Manufacturers, Mic Machinery provides not just machines but complete packaging solutions. We offer:

● Customization Options: Tailored systems to meet unique product and pouch requirements.

● Strong Technical Support: Comprehensive training, installation guidance, and after-sales service.

● Global Reach: Machines trusted by clients across multiple countries.

● Continuous Innovation: Investment in R&D ensures our equipment remains at the cutting edge of packaging technology.

Commitment to Clients

Every Spout Pouch Packing Machine we produce reflects our dedication to quality and performance. By combining advanced engineering with customer-focused design, Mic Machinery helps businesses increase efficiency, reduce costs, and enhance product presentation. Our goal is to be more than a supplier—we aim to be a long-term partner in your success.

Conclusion

If you are searching for reliable Spout Pouch Filling Machine Manufacturers, Mic Machinery stands as your trusted choice. With our professional expertise, advanced technology, and global service network, we deliver equipment that not only meets but exceeds expectations. Partner with Mic Machinery to achieve efficient, innovative, and reliable pouch packaging solutions for your business.

|

Filling Range |

250-2000ml |

|

Voltage |

220v/380v |

|

Power |

4KW |

|

Filling Precision |

99% |

|

Filling Nozzles |

8 nozzles |

|

Filling Speed |

3000 BPH |

|

Dimension |

3800*1500*2200mm |

|

Weight |

1000kg |

|

Material |

SS304 |

|

Touch screen |

Xinjie |

|

PLC |

Schneider |

|

Solenoid valve |

AirTAC |

|

Optoelectronic system |

AUTONICS |

|

Differential switch |

Netherlands |

|

Air source treatment |

AirTAC |

|

Switching power |

MingWei |

|

Button and other low-voltage electrical appliances |

Schneider |

|

Alarm system |

Real-time fault alarm, important fault can automatically stop |

|

Servo motor |

TECO |

|

Ball screw |

Taiwan |

|

Function |

Filling the count |

|

Material |

316 stainless steel is used in contact with material, 304 stainless steel is used in other main parts. |

|

Sealing ring |

It is made of carbon tetrafluoro fibers with good anticorrosion, wear resistance and sealing. |

|

AC contactor |

Schneider |

|

Thermorelay |

Schneider |

|

Transducer |

Schneider |

|

Double clutch |

Custom |

|

Precision relief valve |

Lark |

|

Screw cap form |

Automatic cap sorting and capping |

|

One camera dual use |

Fillable Water Agent or Thickener Formula |