- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction to Semi-Automatic Spout Pouch Filling Machines

In the rapidly evolving packaging industry, pouch filling machines have become essential for businesses aiming to efficiently package liquid and semi-liquid products. Among the various types of pouch filling machines, the semi-automatic spout pouch filling machine stands out for its versatility and efficiency. This article delves into the specifics of semi-automatic spout pouch filling machines, exploring their features, benefits, and performance, while highlighting the importance of keywords such as pouch filling machine, automatic pouch filling machine, and semi-automatic pouch filling machine.

Understanding Spout Pouch Filling Machine

A pouch filling machine is designed to fill pouches with products such as liquids, pastes, or granules. These machines are crucial in industries like food and beverage, pharmaceuticals, and cosmetics, where precise and hygienic packaging is paramount. Pouch filling machines offer several advantages, including reduced material waste, increased filling accuracy, and improved product shelf life.

The Role of Automatic Spout Pouch Filling Machines

An automatic pouch filling machine automates the entire filling process, from feeding the pouches to sealing them after filling. This automation enhances production efficiency, minimizes human error, and ensures consistent product quality. Automatic pouch filling machines are ideal for large-scale production environments where high speed and precision are required. They are equipped with advanced features such as touch screen interfaces, automatic sealing mechanisms, and integrated quality control systems.

Advantages of Semi-Automatic Spout Pouch Filling Machines

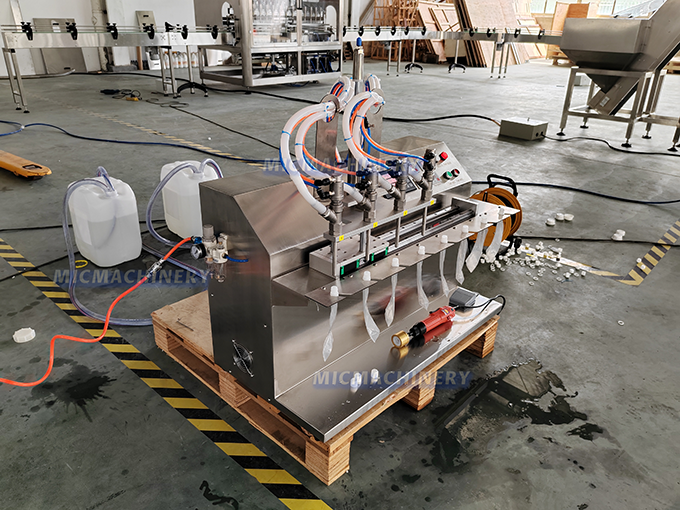

The semi-automatic pouch filling machine offers a balance between manual and automated operations. Unlike fully automatic machines, semi-automatic pouch filling machines require some level of human intervention, which can be advantageous for small to medium-sized businesses. These machines are typically more affordable than their fully automatic counterparts and provide greater flexibility in handling different pouch sizes and product types.

Key Features of Semi-Automatic Spout Pouch Filling Machines

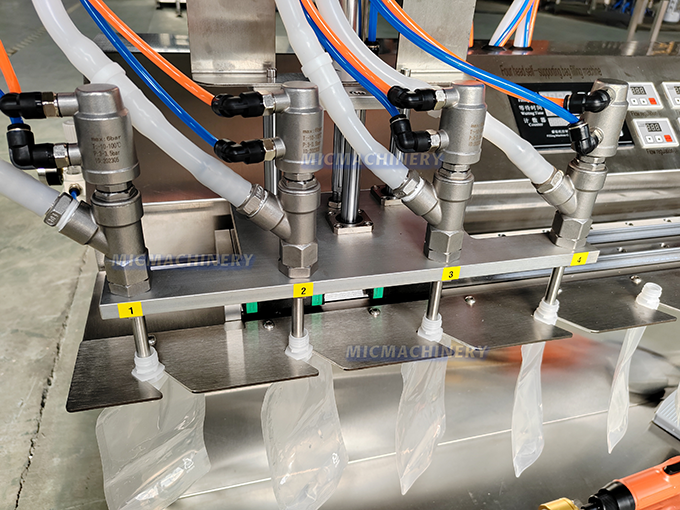

Versatility: Semi-automatic spout pouch filling machines can handle a wide range of products, including liquids, pastes, and gels. This versatility makes them suitable for various industries, from food and beverages to pharmaceuticals and cosmetics.

Ease of Use: These machines are designed with user-friendly interfaces, making them easy to operate even for operators with minimal technical expertise. The semi-automatic nature allows for manual adjustments, ensuring precise filling and reducing the risk of product waste.

Cost-Effectiveness: For businesses with budget constraints, semi-automatic spout pouch filling machines provide a cost-effective solution without compromising on quality. They require a lower initial investment compared to fully automatic machines and have lower maintenance costs.

Flexibility: The semi-automatic spout pouch filling machine offers flexibility in terms of production volume. Businesses can scale their operations up or down based on demand without significant changes to the machine setup.

Precision and Hygiene: These machines are equipped with precise filling mechanisms that ensure accurate product quantities in each pouch. They are also designed to meet stringent hygiene standards, making them suitable for food and pharmaceutical applications.

In conclusion, the semi-automatic spout pouch filling machine is an invaluable asset for businesses looking to improve their packaging processes. Its combination of versatility, cost-effectiveness, and ease of use makes it a preferred choice for many industries. By focusing on these keywords, you not only provide valuable information to your readers but also optimize your content for better search engine visibility.

In the rapidly evolving packaging industry, pouch filling machines have become essential for businesses aiming to efficiently package liquid and semi-liquid products. Among the various types of pouch filling machines, the semi-automatic spout pouch filling machine stands out for its versatility and efficiency. This article delves into the specifics of semi-automatic spout pouch filling machines, exploring their features, benefits, and performance, while highlighting the importance of keywords such as pouch filling machine, automatic pouch filling machine, and semi-automatic pouch filling machine.

Understanding Spout Pouch Filling Machine

A pouch filling machine is designed to fill pouches with products such as liquids, pastes, or granules. These machines are crucial in industries like food and beverage, pharmaceuticals, and cosmetics, where precise and hygienic packaging is paramount. Pouch filling machines offer several advantages, including reduced material waste, increased filling accuracy, and improved product shelf life.

The Role of Automatic Spout Pouch Filling Machines

An automatic pouch filling machine automates the entire filling process, from feeding the pouches to sealing them after filling. This automation enhances production efficiency, minimizes human error, and ensures consistent product quality. Automatic pouch filling machines are ideal for large-scale production environments where high speed and precision are required. They are equipped with advanced features such as touch screen interfaces, automatic sealing mechanisms, and integrated quality control systems.

Advantages of Semi-Automatic Spout Pouch Filling Machines

The semi-automatic pouch filling machine offers a balance between manual and automated operations. Unlike fully automatic machines, semi-automatic pouch filling machines require some level of human intervention, which can be advantageous for small to medium-sized businesses. These machines are typically more affordable than their fully automatic counterparts and provide greater flexibility in handling different pouch sizes and product types.

Key Features of Semi-Automatic Spout Pouch Filling Machines

Versatility: Semi-automatic spout pouch filling machines can handle a wide range of products, including liquids, pastes, and gels. This versatility makes them suitable for various industries, from food and beverages to pharmaceuticals and cosmetics.

Ease of Use: These machines are designed with user-friendly interfaces, making them easy to operate even for operators with minimal technical expertise. The semi-automatic nature allows for manual adjustments, ensuring precise filling and reducing the risk of product waste.

Cost-Effectiveness: For businesses with budget constraints, semi-automatic spout pouch filling machines provide a cost-effective solution without compromising on quality. They require a lower initial investment compared to fully automatic machines and have lower maintenance costs.

Flexibility: The semi-automatic spout pouch filling machine offers flexibility in terms of production volume. Businesses can scale their operations up or down based on demand without significant changes to the machine setup.

Precision and Hygiene: These machines are equipped with precise filling mechanisms that ensure accurate product quantities in each pouch. They are also designed to meet stringent hygiene standards, making them suitable for food and pharmaceutical applications.

In conclusion, the semi-automatic spout pouch filling machine is an invaluable asset for businesses looking to improve their packaging processes. Its combination of versatility, cost-effectiveness, and ease of use makes it a preferred choice for many industries. By focusing on these keywords, you not only provide valuable information to your readers but also optimize your content for better search engine visibility.