- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Precision and Efficiency: The Role of Vape Pen Filling Machines in E-Liquid Production

In the realm of e-liquid manufacturing, the demand for precision and efficiency has never been higher, especially in the burgeoning vape pen market. Vape Pen Filling Machines have emerged as essential tools, offering unparalleled performance tailored to the exacting standards of the industry. Let's explore the significance of these machines, focusing on their role as E-Liquid Filling Machines, vape pen filling machines, and automatic e-liquid filling machines.

Maximizing Performance with Vape Pen Filling Machines

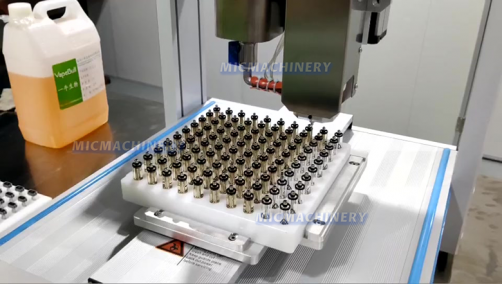

Precision E-Liquid Filling: Vape Pen Filling Machines are engineered to deliver precise fills into vape pen cartridges with unmatched accuracy. Equipped with advanced dosing mechanisms and controls, they ensure consistent fills, maintaining product quality and customer satisfaction. From standard vape pen cartridges to specialized formulations, these machines cater to a diverse range of e-liquid products.

Efficiency in Production: Designed for high-speed production, Vape Pen Filling Machines optimize throughput while minimizing downtime. Their automated features streamline the filling process, enabling rapid and reliable fills across production runs. By reducing manual labor and optimizing workflow efficiency, these machines enhance overall productivity in vape pen manufacturing operations.

Versatility and Adaptability: Serving as versatile solutions, Vape Pen Filling Machines accommodate various vape pen cartridge sizes and styles commonly used in the industry. Whether filling standard 510 cartridges, disposable pods, or proprietary designs, they adapt seamlessly to different packaging formats, providing flexibility in production setups.

Serving as E-Liquid Filling Machines, Vape Pen Filling Machines, and Automatic E-Liquid Filling Machines

E-Liquid Filling Machines: These machines serve as dedicated e-liquid filling solutions, excelling in precision and efficiency to meet the stringent requirements of the vape pen industry. Their customizable features and intuitive controls make them indispensable for manufacturers seeking consistent quality in their e-liquid formulations.

Vape Pen Filling Machines: Specifically tailored for filling vape pen cartridges, these machines optimize the filling process for different cartridge styles and formulations. Their robust construction and user-friendly interface simplify operation, facilitating seamless integration into vape pen production lines.

Automatic E-Liquid Filling Machines: With automated capabilities, these machines revolutionize vape pen production workflows, minimizing human intervention and ensuring uniform fills across batches. Their programmable settings enable precise control over dosing and filling parameters, guaranteeing reliable and high-quality e-liquid products with every fill.

Conclusion

Vape Pen Filling Machines play a pivotal role in the success of e-liquid manufacturers, offering precision, efficiency, and versatility in vape pen production. Whether serving as E-Liquid Filling Machines, vape pen filling machines, or automatic e-liquid filling machines, their performance optimizes production processes, upholds product integrity, and satisfies consumer demand. By investing in these cutting-edge solutions, manufacturers can streamline their vape pen production, meet market demands, and remain competitive in the rapidly evolving vape industry.

In the realm of e-liquid manufacturing, the demand for precision and efficiency has never been higher, especially in the burgeoning vape pen market. Vape Pen Filling Machines have emerged as essential tools, offering unparalleled performance tailored to the exacting standards of the industry. Let's explore the significance of these machines, focusing on their role as E-Liquid Filling Machines, vape pen filling machines, and automatic e-liquid filling machines.

Maximizing Performance with Vape Pen Filling Machines

Precision E-Liquid Filling: Vape Pen Filling Machines are engineered to deliver precise fills into vape pen cartridges with unmatched accuracy. Equipped with advanced dosing mechanisms and controls, they ensure consistent fills, maintaining product quality and customer satisfaction. From standard vape pen cartridges to specialized formulations, these machines cater to a diverse range of e-liquid products.

Efficiency in Production: Designed for high-speed production, Vape Pen Filling Machines optimize throughput while minimizing downtime. Their automated features streamline the filling process, enabling rapid and reliable fills across production runs. By reducing manual labor and optimizing workflow efficiency, these machines enhance overall productivity in vape pen manufacturing operations.

Versatility and Adaptability: Serving as versatile solutions, Vape Pen Filling Machines accommodate various vape pen cartridge sizes and styles commonly used in the industry. Whether filling standard 510 cartridges, disposable pods, or proprietary designs, they adapt seamlessly to different packaging formats, providing flexibility in production setups.

Serving as E-Liquid Filling Machines, Vape Pen Filling Machines, and Automatic E-Liquid Filling Machines

E-Liquid Filling Machines: These machines serve as dedicated e-liquid filling solutions, excelling in precision and efficiency to meet the stringent requirements of the vape pen industry. Their customizable features and intuitive controls make them indispensable for manufacturers seeking consistent quality in their e-liquid formulations.

Vape Pen Filling Machines: Specifically tailored for filling vape pen cartridges, these machines optimize the filling process for different cartridge styles and formulations. Their robust construction and user-friendly interface simplify operation, facilitating seamless integration into vape pen production lines.

Automatic E-Liquid Filling Machines: With automated capabilities, these machines revolutionize vape pen production workflows, minimizing human intervention and ensuring uniform fills across batches. Their programmable settings enable precise control over dosing and filling parameters, guaranteeing reliable and high-quality e-liquid products with every fill.

Conclusion

Vape Pen Filling Machines play a pivotal role in the success of e-liquid manufacturers, offering precision, efficiency, and versatility in vape pen production. Whether serving as E-Liquid Filling Machines, vape pen filling machines, or automatic e-liquid filling machines, their performance optimizes production processes, upholds product integrity, and satisfies consumer demand. By investing in these cutting-edge solutions, manufacturers can streamline their vape pen production, meet market demands, and remain competitive in the rapidly evolving vape industry.