- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the realm of pharmaceutical manufacturing, precision, efficiency, and reliability are paramount for ensuring the quality and safety of medicinal products. The Stand-Up Bag Pharmaceutical Packing Machine emerges as a crucial component in this process, offering advanced solutions for packaging pharmaceutical products in convenient and secure stand-up bags. Let's explore its performance, focusing on its role as a pharmaceutical filling machine, pharmaceutical packing machine, and pharmaceutical filling equipment.

Maximizing Performance with Stand-Up Bag Pharmaceutical Packing Machine

Precision Packaging: The Stand-Up Bag Pharmaceutical Packing Machine excels in delivering precise and consistent packaging for pharmaceutical products. Equipped with state-of-the-art technology and precise controls, it ensures accurate sealing, labeling, and packaging, critical for maintaining product integrity and compliance with regulatory standards.

Efficiency and Speed: As a high-speed pharmaceutical filling machine, this equipment boasts rapid packaging capabilities, significantly reducing production time and increasing throughput. Its efficient operation minimizes downtime and enhances productivity, enabling pharmaceutical manufacturers to meet demanding production schedules effectively.

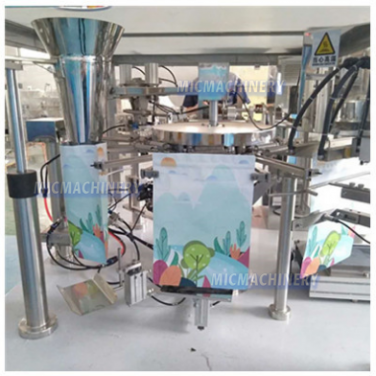

Versatility and Adaptability: Serving as pharmaceutical filling equipment, this machinery offers versatility in handling various packaging formats, including stand-up bags, pouches, sachets, and more. Whether packaging solid doses, liquids, or powders, it adapts seamlessly to diverse production requirements, accommodating different pharmaceutical products with ease.

Serving as a Pharmaceutical Filling Machine, Pharmaceutical Packing Machine, and Pharmaceutical Filling Equipment

Pharmaceutical Filling Machine: The Stand-Up Bag Pharmaceutical Packing Machine serves as a specialized solution for filling pharmaceutical products accurately and efficiently. Its robust construction and precise dosing mechanisms ensure consistent fills, minimizing product wastage and maximizing dosage accuracy for pharmaceutical formulations.

Pharmaceutical Packing Machine: Tailored specifically for stand-up bag packaging applications, this equipment excels in ensuring the quality and integrity of pharmaceutical products throughout the packaging process. From sealing and labeling to serialization and inspection, it upholds stringent standards, safeguarding the safety and efficacy of medicinal products.

Pharmaceutical Filling Equipment: As comprehensive pharmaceutical filling equipment, this machinery encompasses multiple components, including filling stations, sealing units, labeling systems, and inspection devices. Its modular design allows for seamless integration into existing production lines, providing a complete solution for pharmaceutical manufacturers to streamline their packaging processes.

Conclusion

The Stand-Up Bag Pharmaceutical Packing Machine plays a pivotal role in pharmaceutical manufacturing, offering precision, efficiency, and versatility in packaging pharmaceutical products in stand-up bags. Whether serving as a pharmaceutical filling machine, pharmaceutical packing machine, or complete filling equipment, it ensures the quality, integrity, and compliance of medicinal products throughout the packaging process. By investing in this advanced equipment, pharmaceutical manufacturers can enhance their production capabilities, meet regulatory requirements, and uphold their commitment to delivering safe and effective pharmaceutical products to consumers.

1.This machine uses frequency conversion speed regulation device, which can adjust the speed at will within the specified range.

2.Automatic detection function, if the bag is not opened or opened incompletely, no feeding, no heat sealing, the bag can be reused, no waste of materials, saving production costs for users.

3.The safety device will give an alarm when the working air pressure is abnormal or the heating pipe fails.

4.Equipped with plexiglass safety door to protect operators.

5.Oil-free vacuum pump is adopted to avoid pollution of the production environment.

Suitable for milk powder,coffee,flour,spices,additive,pesticide,chemical powder weighing filling packing for premade bag,zipper bag.

Adopting PLC control,it has the advantages of stable operation and high weighing accuracy.

The width of the bag is easy to adjust and can be controlled with just one button.

Comply with GMP requirements, environmental protection and pollution-free.

All contact parts are made of 304/316 stainless steel.

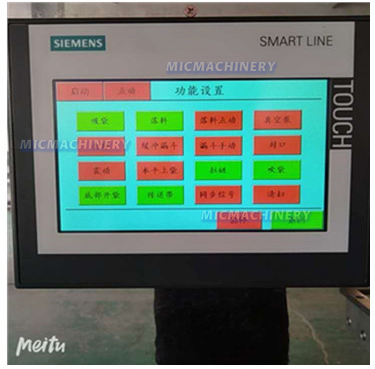

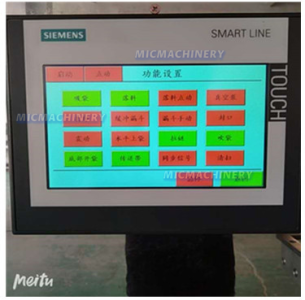

control panel

The control panel on the filling machine is the core of the machine,it consists of touch screen,power switch, emergency button You just need to press the corresponding button and the machine will follow the correct program.

An Alarm Screen will also be included on automatic filling equipment to notify packagers when there is an issue with the filling equipment or the packaging line in general. In addition to notification, the screen can assist with identifying the issue if the same is not immediately obvious.

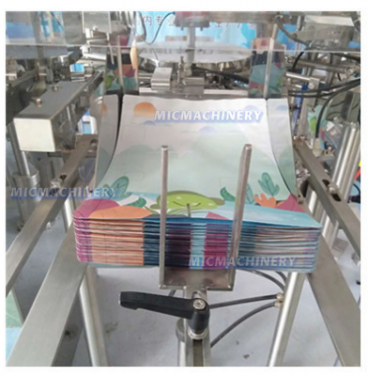

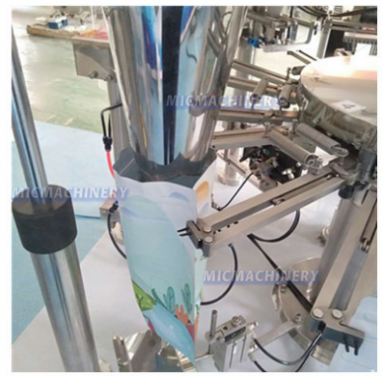

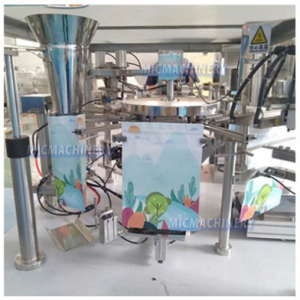

Automatic bag opening device

Its main function is to open the bag and prepare the filling material

Main work flow: suction cup will bring the bag to the main rotary plate, the main rotary plate holds the bag into the vacuum bag opening station. The bag is vacuumed by suction cups and assists in blowing air out. After the bag is opened, the filling begins, then the bag is sealed, and the final product is conveyed out of the filling machine through a conveyor belt

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback: