- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

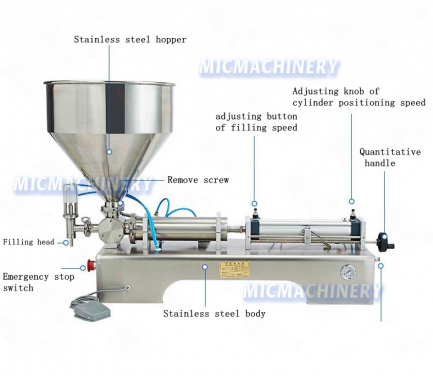

In the heart of culinary craftsmanship, where recipes are perfected and flavors are celebrated, the Manual Sauce Filling Machine(Sauce Filling Equipment) stands as a symbol of precision and tradition. This innovative device seamlessly merges the artistry of sauce creation with hands-on efficiency, transforming how sauces are filled and brought to tables worldwide. By exploring its unique product characteristics, versatile applications, and the fundamental mechanical principles guiding its operation, one can truly appreciate its pivotal role in the food industry. From small-scale artisanal kitchens to specialty food stores and catering services, this manual machine ensures that every bottle and jar is filled with the authentic essence of sauces, enhancing culinary experiences with every dollop.

Product Characteristics:

The Manual Sauce Filling Machine(Sauce Filling Equipment) boasts distinctive product characteristics tailored for accuracy and ease of use. Crafted from durable, food-grade materials, these machines are compact and user-friendly, making them ideal for small-scale producers and culinary enthusiasts. Featuring adjustable filling nozzles and precision dosing mechanisms, they ensure consistent filling, minimizing spillage and optimizing resource utilization. The machines are easy to clean and maintain, promising longevity and reliability, coupled with customizable settings to accommodate various sauce viscosities, from thin marinades to thick gravies.

Product Applications:

The applications of the Manual Sauce Filling Machine are diverse and indispensable within the culinary world. Artisanal sauce makers and small-scale producers rely on these machines to maintain the authenticity and quality of their sauces, ensuring accurate portions and preserving the homemade essence. Gourmet restaurants and catering services benefit from the precision of these machines, enhancing the presentation and portion control of their signature dishes, meeting the high standards of chefs and diners. Additionally, specialty food stores and farmers' markets utilize these machines to offer unique, handcrafted sauces, catering to discerning customers appreciative of the artisanal touch.

Mechanical Principle:

At its core, the Manual Sauce Filling Machine operates on fundamental mechanical principles designed for simplicity and accuracy. Utilizing a manual filling nozzle and gravity-based flow control, producers fill sauces into individual bottles or jars with precision, ensuring consistent portions. The machines feature hand-operated levers or valves, allowing producers to regulate the sauce flow accurately. The containers are manually placed and removed, ensuring a hands-on approach to the filling process. Although manual, these machines offer a level of control and customization prized by artisanal producers, preserving the individual character of their sauces.

In conclusion, the Manual Sauce Filling Machine embodies the essence of hands-on craftsmanship in the culinary industry. Its unique product characteristics, tailored applications, and fundamental mechanical principles make it an invaluable tool for small-scale sauce artisans, culinary enthusiasts, and local producers. Embracing the charm of traditional methods while incorporating modern convenience, this machine not only fills sauce bottles but also preserves the artistry and authenticity of homemade culinary creations. As an essential companion for those passionate about crafting exceptional sauces, it continues to shape the way sauces are presented, purchased, and enjoyed, making it a vital element in the ever-evolving world of gastronomy and culinary arts.

Filling Head

When the bottle comes under the filling head, cylinder head began to move down the drive filling, filling process without dripping, do not waste material, also can ensure the bottle clean and tidy.

The size of the filling head can be customized according to the caliber of the bottle, ensuring that this machine is absolutely suitable for your product

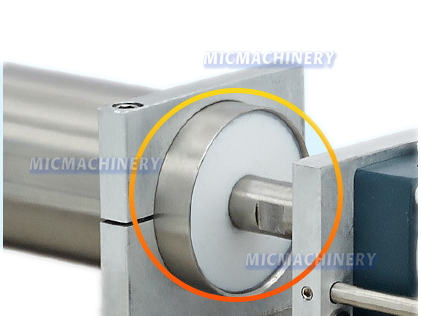

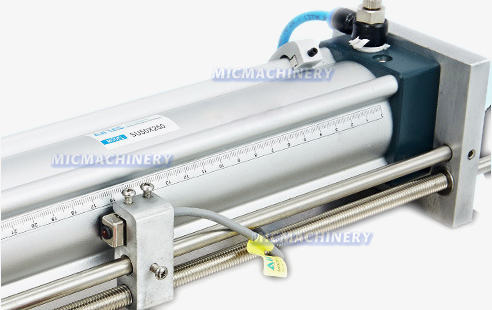

Air Cylinder

The cylinder is through the internal pumping system, the material out from the material cylinder, and then in the filling. Driven by electricity and air compressor.The machine is all made of SUS304. Corrosion-resistant, compact structure, easy to operate, beautiful appearance, in line with GMP standards.

if you want to know more models of filling machine, you can refer to the table below

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed |

5-25 B/M |

192-220 B/h (basis on 25L) |

1300-1500 B/h (basis on100ml bottle) |

≤1800 B/h ( basis on 1000ml bottle) |

3000B/h (basis on 350ml) |

3200 B /h |

≤4000 B/h (basis on1L bottle) |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.0Kw |

2.8kw |

3kw |

2.8kw |

2Kw |

3.0Kw |

|

Size |

1000*480*700 mm |

2500*1600*2500 mm |

1840*1400*2500 mm |

2000*1400*2500 mm |

1600*1400*2300 mm

|

2440*1240*2350 mm |

2800 *1400*2500 mm |

|

Weight |

35 Kg |

700 kg |

600kg |

1000kg |

3000Kg |

700 kg |

1000 kg |

2. Filling volume can be easily adjusted.

3. The machine is all made of SUS304. Corrosion-resistant, compact structure, easy to operate, beautiful appearance, in line with GMP standards.

4. It can work automatically or controlled by a operation pedal.

5. Has single head, double heads and full pneumatic model. Our machine support special customization.

6. It is suitable for filling liquid and paste materials such as water, juice, oil, sauce, toothpaste, cosmetic cream, hand cream, honey, peanut butter etc. lt is widely used in chemical industry, food, cosmetic, medicine, etc.

In addition to,If you're looking for sauce packaging machine,sauce filling equipment,sauce packing machine,chili sauce packing machine,mayonnaise packing machine,sauce packing machine price,it is a pleasure for you to visit our website anytime.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback:

|

Model |

MIC V01 |

|

Voltage |

220V/380V 50/60HZ |

|

Power |

30W |

|

Air Pressure |

0.4-0.6MPa |

|

Filling Speed |

5-25 bottles/min |

|

Filling Accuracy |

±1% |

|

Dimension(L*W*H) |

1000*480*700mm |

|

Filling Range |

10-20ML. 25-250ML. 50-500ML.100-1000ML.250-2500ML. 1000-5000ML |

|

Weight |

35 Kg |

|

Filling Material |

Juice, Oil, Water, Sauce, Toothpaste, Cosmetic Cream, Hand Cream, Honey and etc |

|

Note: If you need special customization. please feel free contact me. |

|

- MIC Sauce Piston Filling Equipment

- MIC Sauce Gravity Bottle Filling Equipment

- MIC Sauce Gravity Filling Equipment

- MIC-ZF20 Sauce Packaging Machine ( Sauce, Paste, Oil, 4000 Bottles/h )

- MIC Hot Sauce Packing Machine ( Paste, Yogurt, Sauce, 30-35 Cups/min )

- MIC Sauce Packing Machine ( Honey, Oil, Sauce, 12000 Bottles/h )

- MIC Mayonnaise Packing Machine ( Mayonnaise, Paste, Honey, 10-50 Bags/min )

- MIC ZG-1 Sauce Filling Equipment ( Paste, Liquid, Cosmetic, 1-50 Bottles/min )

- MIC Chili Sauce Packing Machine ( Honey, Ketchup, Sauce, 20-40 Bags/min )

- MIC-V01 Manual Sauce Filling Machine ( Cosmetic, Lip balm, 5-25 Bottles/min )