- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

In the sphere of product manufacturing, where precision and efficiency are paramount, the Tincture Bottle Filling Machine emerges as a versatile solution. Seamlessly blending technological innovation with operational efficacy, this machine bridges the gap between manual labor and automated production, offering manufacturers a reliable tool for filling tincture bottles with accuracy and speed. Let's delve into its unique characteristics, diverse applications, and intricate mechanical principles, elucidating its role in revolutionizing production processes across industries.

Product Characteristics:

The Tincture Bottle Filling Machine showcases a plethora of exceptional features meticulously designed for precise and efficient filling operations. Crafted from durable materials, such as stainless steel, it ensures longevity and adherence to rigorous quality standards. Equipped with semi-automated dosing systems, customizable settings, and intuitive interfaces, this machine strikes a harmonious balance between automation and manual intervention. Its adaptable controls accommodate a spectrum of product viscosities, ensuring consistent and accurate fills for each tincture bottle. With anti-drip mechanisms and secure sealing, it preserves the integrity of formulations, delivering products of unparalleled quality and reliability.

Product Applications:

The applications of the Tincture Bottle Filling Machine cater to a wide range of industries and product formulations. Ideal for small to medium-scale production, it excels in filling specialized tinctures, extracts, and solutions where precision is critical. Manufacturers leverage its versatility for custom formulations, ensuring each tincture bottle receives a tailored fill. Whether dispensing herbal remedies, pharmaceutical solutions, or cosmetic serums, the Tincture Bottle Filling Machine serves as an indispensable tool for achieving production excellence with precision and efficiency.

Mechanical Principle:

At its core, the Tincture Bottle Filling Machine operates on advanced mechanical principles engineered for accuracy and adaptability. Utilizing semi-automated dosing pumps, conveyor systems, and precision filling nozzles, it precisely measures and dispenses predetermined quantities of liquid into individual bottles. Temperature controls maintain optimal product consistency, while integrated sensors and programmable logic controllers oversee the filling process with precision. This meticulous approach minimizes errors and maximizes efficiency, ensuring uniformity while streamlining production operations.

In conclusion, the Tincture Bottle Filling Machine stands as a testament to the synergy between technology and operational excellence in manufacturing. Its exceptional characteristics, diverse applications, and balanced mechanical principles make it an indispensable asset for producers seeking to elevate production precision and efficiency. As a cornerstone of modern production processes, it continues to redefine industry standards, ensuring each tincture bottle embodies the essence of precision, reliability, and operational excellence.

Negative pressure filling

1. It can keep your finished product level at the same level with very little error. If your product container is made transparent, it can have a better visual effect in sales

2.It can be filled without dripping When filling without dripping, the cosmetic industry also needs to achieve a high standard of hygiene, negative vacuum filling without dripping to avoid the risk of cross infection

3.It is also very suitable for the filling of liquid which is easy to bubble during the filling process. Because this machine will suck all the foam in the bottle mouth at the end. The sucked foam and liquid will enter the liquid storage tank and it will not be wasted.

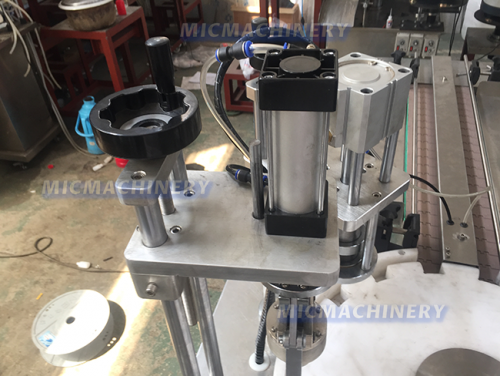

The machine’s chuck

The chuck is used to fix the filling container and drive the container to move to the filling、capping and other stations. The circular design can save space while setting up multiple positions, so that the filling process is time-saving and efficient and it is clear function and easy to clean.

We can customize the right tray for you for the size and shape of your packaging container

If you want to know more models of filling machine, you can refer to the table below:

|

Vial Filling Machine |

||||||||

|

model |

FC-30 |

FC-X40 |

FC-P35 |

FC-P40 |

FC-T30 |

FC-N25 |

FC-E35 |

FC-Z40 |

|

application |

cosmetics, daily chemical and pharmaceutical industries such as nail polish, e-liquid, eye drop,sauce,etc |

|||||||

|

Packing type |

various round and flat glass and plastic bottles,etc |

|||||||

|

speed |

25-30p/m |

30-50p/m |

30-40p/m |

25-30p/m |

20-30p/m |

15-25p/m |

30-40p/m |

30-50p/m |

|

Filling arrange |

50-250ML |

10-100ML |

10-100ML |

10-100ML |

30-120ML |

2-30ML |

10-100ML |

20-150ML |

|

power |

5kw |

2KW |

2KW |

5KW |

2KW |

2KW |

2KW |

2KW |

|

size |

2000*1000*1700mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

2000*1000*1500mm |

|

weight |

650KG |

550KG |

650KG |

650KW |

650KG |

650KG |

650KG |

600KG |

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.