- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

In the realm of skincare manufacturing, where precision and craftsmanship converge, the Tincture Filling Machine emerges as a versatile solution, seamlessly blending technological innovation with the human touch in the creation of beauty essentials. This cutting-edge machine bridges the gap between manual artistry and automated efficiency, offering skincare manufacturers a reliable tool for nuanced applications. By unraveling its unique product characteristics, diverse applications, and the intricate mechanical principles guiding its operation, we explore the essence of excellence in tincture filling. From bespoke formulations to specialized serums, this machine ensures each skincare product is dispensed with a harmonious balance of precision and artisanal care.

Product Characteristics:

The Tincture Filling Machine showcases an array of exceptional characteristics meticulously engineered for precision and efficiency. Crafted from durable materials, often stainless steel, these machines ensure longevity while adhering to the highest standards of quality. Featuring automated dosing systems, filling nozzles, and customizable settings, they offer a delicate balance between automation and the human touch. Designed with user-friendly interfaces and adjustable controls, these machines accommodate a spectrum of tincture viscosities, ensuring each product receives a consistent and accurate fill. Equipped with anti-drip mechanisms and secure sealing, these machines preserve the integrity of tincture formulations, delivering products that resonate with both quality and the personal touch of craftsmanship.

Product Applications:

The applications of the Tincture Filling Machine cater to the nuanced demands of skincare formulations. Ideal for small to medium-scale production, these machines are favored for crafting specialized tinctures, oils, and serums where precision and attention to detail are paramount. Skincare manufacturers embrace the versatility of these machines for custom formulations, ensuring each product receives a personalized touch. Whether infusing herbal remedies or formulating therapeutic blends, the Tincture Filling Machine stands as a reliable partner in the pursuit of skincare excellence.

Mechanical Principle:

At its core, the Tincture Filling Machine operates on advanced mechanical principles designed for precision, flexibility, and a seamless blend of automation with manual intervention. Utilizing automated dosing pumps, conveyor systems, and filling nozzles, the machine accurately measures and dispenses the specified quantity of tinctures into individual containers. Temperature controls ensure the formulations remain at optimal consistency, while integrated sensors and programmable logic controllers (PLCs) oversee the entire automated process. The precision of the machine guarantees uniformity, minimizing errors and enhancing the overall efficiency of tincture filling operations while leaving room for the human touch in the formulation process.

In conclusion, the Tincture Filling Machine stands as a symbol of harmonious synergy between technology and artisanal craftsmanship in the skincare manufacturing realm. Its exceptional product characteristics, diverse applications, and balanced mechanical principles make it an indispensable asset for skincare manufacturers seeking the ideal blend of precision and personalized care. As a fundamental component in the creation of bespoke skincare essentials, it continues to shape the way skincare products are filled, ensuring each product embodies the essence of precision, efficiency, and the artisanal touch that defines the beauty industry.

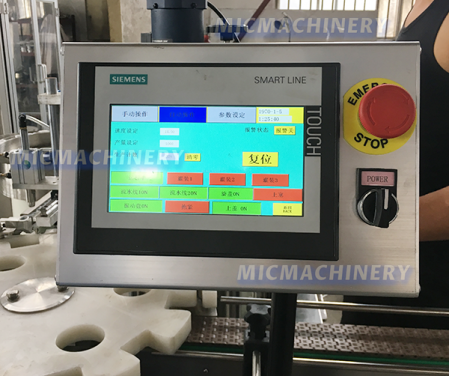

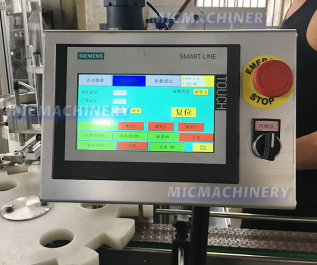

Control panel by Siemens touch screen

The control panel on the filling machine is the core of the machine,it consists of touch screen,power switch, emergency button You just need to press the corresponding button and the machine will follow the correct program.

An Alarm Screen will also be included on automatic filling equipment to notify packagers when there is an issue with the filling equipment or the packaging line in general. In addition to notification, the screen can assist with identifying the issue if the same is not immediately obvious.

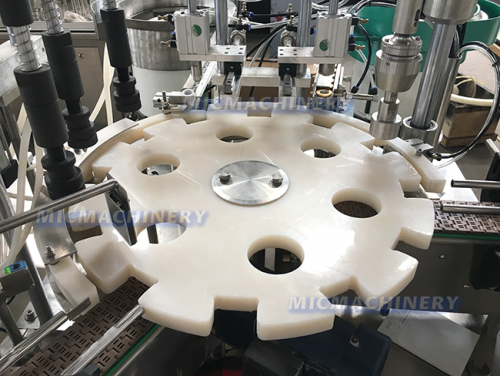

The main platform

The picture includes chuck, negative vacuum filling head,and automatic lid feeding and lid tightening stations.They are clear function and easy to clean.

Among them, the chuck is used to fix the filling container and drive the container to move to the filling capping and other stations. The circular design can save space while setting up multiple positions, so that the filling process is time-saving and efficient

We can customize this turntable, filling head, screw cap and so on.

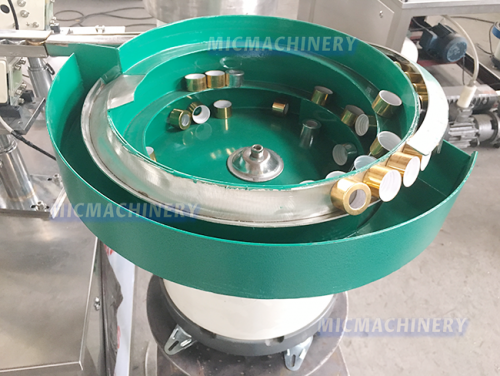

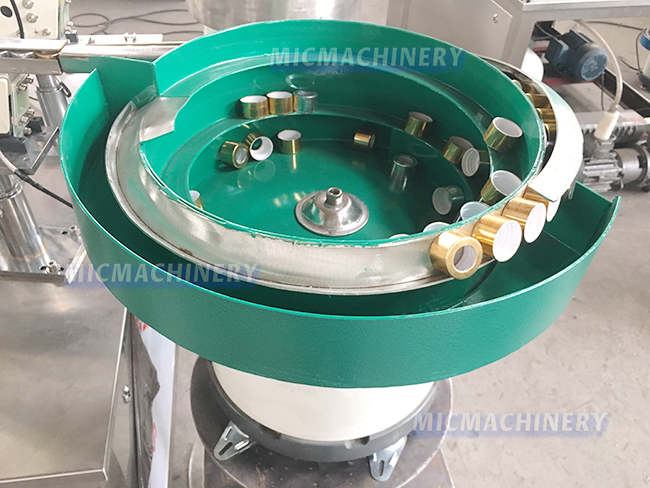

Cap loading automatically

Cap feeding cage with vibrating piate is connected to a pipe that carries the cap ,They automatically arranges the cap and deliver the cap.

In this way, the bottle is covered in a consistent process, reducing the manual contact with the bottle process, and ensuring better hygiene,At the same time, labor costs are reduced.

If you want to know more models of filling machine, you can refer to the table below:

|

Vial Filling Machine |

||||||||

|

model |

FC-30 |

FC-X40 |

FC-P35 |

FC-P40 |

FC-T30 |

FC-N25 |

FC-E35 |

FC-Z40 |

|

application |

cosmetics, daily chemical and pharmaceutical industries such as nail polish, e-liquid, eye drop,etc |

|||||||

|

Packing type |

various round and flat glass and plastic bottles,etc |

|||||||

|

speed |

23-30 pcs/min |

30-50 pcs/min |

30-40 pcs/min |

25-30 pcs/min |

20-30 pcs/min |

15-25 pcs/min |

30-40 pcs/min |

30-50 pcs/min |

|

Filling arrange |

50-250ML |

10-100 ML |

10-100 ML |

10-100 ML |

30-120 ML |

2-30 ML |

10-100 ML |

20-150 ML |

|

power |

5kw |

2KW |

2KW |

5KW |

2KW |

2KW |

2KW |

2KW |

|

size |

2000*1000*1700mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

2000*1000*1500mm |

|

weight |

650KG |

550KG |

650KG |

650KW |

650KG |

650KG |

650KG |

600KG |

In addition to,we have tincture bottle filling machine,tincture filling machine,tincture bottle filler,tincture bottling machine,automatic tincture filling machine,If you are more than interested in the machine ,you can contact us at market@micmachinery.com