- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

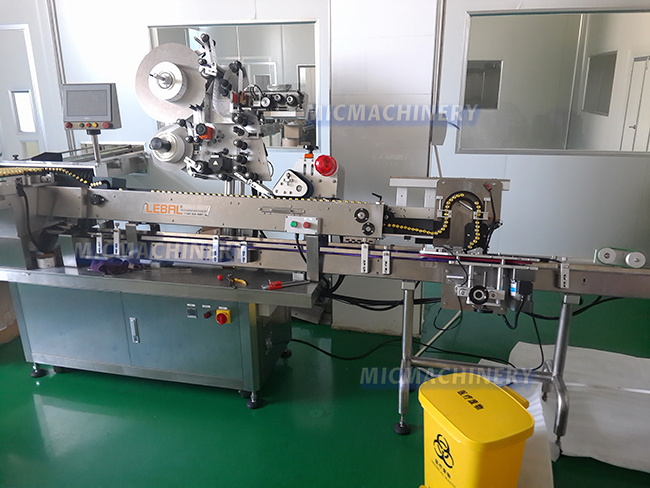

Round bottles with different specifications by the transformation mechanism into the labeling machine conveyor belt, the conveyor belt to drive into the bottle labeling area, detected by the electric eye vision after the bottle, the transmission of photoelectric signal to the PLC, the PLC processing after the transmission of the output signal to the servo motor, marked out by the servo motor, by rolling the label on the bottle, labeling of the bottle by labeling machine conveyor belt into the next process or container.

Ii. Motor system:

Omron servo labeling system, omron PLC and function module, omron servo main motor marking, omron frequency adjustment: high stability and synchronization, the fastest reaction time up to 1200 times/minute, and strong torque, never out of step.

Iii. Omron computer control system in Japan:

Real FUZZY(intelligent) no setting, no adjustment, as long as the boot, the system has completed all labeling calculus and preparation, press the start button to paste the perfect product.

Iv. Operation mode:

A. The imported touch-control man-machine interface is adopted, and the display is all in Chinese. As long as the operation is conducted according to the instructions on the display screen, no experience is required, it can be easily put online, greatly reducing the training time of personnel;Through the man-machine interface, the production speed can be set at will, and the production speed can be adjusted automatically.B. If there is any abnormal fault: if the label is used up, the band is broken or tension is missed, the counting setting arrives, the machine is abnormal and so on, it will automatically stop the machine and give an alarm.

V. mechanical design:

1. Super wear-resistant label rolling mechanism, using special teflon material, durable without wear.2. Accurate differential bottling mechanism, the bottling accuracy is as high as ±5mm, it is unnecessary to change accessories for bottles of different specifications, saving cost, easy to adjust, and better than other brands.

3. The stable and durable frame and various parts adopt standardized modular design with complete interchangeability and operate 24 hours a day to ensure safety and stability.

4. The case, made of stainless steel SUS304 and T6 aluminum alloy, never rusts and complies with GMP standard.

· the printing head adopts the solenoid valve to control the cylinder for reciprocating movement. Compared with the movement mode of crank connecting rod, the reaction speed and printing speed are greatly improved.

· the printable manufacturing date, production batch number and expiry date can be completed at the same time, and the printing direction can be adjusted according to user needs.The writing is clear and clean.

Omron Servo Labeling System

Omron servo labeling system, omron PLC and function module, omron servo main motor marking, omron frequency adjustment: high stability and synchronization, the fastest reaction time up to 1200 times/minute, and strong torque, never out of step.

Working Principle

Round bottles with different specifications by the transformation mechanism into the labeling machine conveyor belt, the conveyor belt to drive into the bottle labeling area, detected by the electric eye vision after the bottle, the transmission of photoelectric signal to the PLC, the PLC processing after the transmission of the output signal to the servo motor, marked out by the servo motor, by rolling the label on the bottle, labeling of the bottle by labeling machine conveyor belt into the next process or container.

In addition to,If you're looking for tube labeling machine,vial labeling machine,vial sticker labeling machine,horizontal labeling machine,syringe labeling machine,Please feel free to visit our website.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Voltage specification |

220V 50/60hz |

|

Air pressure supply |

5KG |

|

Power consumption |

2.5KW |

|

Printer air source |

5Kg/cm2 |

|

Labeling speed |

400 bottles/min (speed adjustable, depending on bottle size and label length) |

|

Labeling accuracy |

±0.5mm |

|

Container range |

outside diameter 10mm ~ 22mm, height 20mm ~ 120mm |

|

Label specification |

height 10mm ~ 90mm length 10mm ~ 80mm |

|

Paper roll diameter |

ф 76 mm, outside the paper roll roll: ф 350 mm (maximum) |

|

Label clearance |

3mm, label roll clockwise |

|

Weight |

N.W, G.W 350 kg/T: 450 kg |

|

External dimensions |

2500mm×1650mm×1300mm |

|

Part name |

label |

place of origin |

|

Labeled motor |

omron |

Japan |

|

Labeled motor drive |

omron |

Japan |

|

Conveyor belt motor |

A battery |

shanghai |

|

Conveyor belt motor gear box |

shanghai |

|

|

Paper horse |

lapping |

Germany |

|

Paper horse up to gear box |

||

|

Wheel attached motor |

||

|

Wheel attached motor gear box |

||

|

Separating motor |

||

|

Separating motor gear box |

||

|

Frequency converter |

omron |

Japan |

|

Label eye |

keyence |

Japan |

|

Label detected electric eye |

keyence |

Japan |

|

Receiving stop proximity switch |

omron |

Japan |

|

Programmable controller (PLC) |

omron |

Japan |

|

Electromagnetic relay |

omron |

Japan |

|

Electromagnetic valve |

Japan |

|

|

Thermostat |

omron |

Japan |

|

Proximity switch |

omron |

Japan |

|

Marking machine |

pneumatic |

Japan |

|

Cylinder |

SMC |

Japan |