Whether you're producing small batches for niche brands or handling large-scale manufacturing for popular retailers, a nail polish filling and capping machine is an investment that can transform your operations. In this guide, we’ll explore the types, benefits, and features of these machines, helping you understand how they can revolutionize your business.

Types of Nail Polish Filling Machines

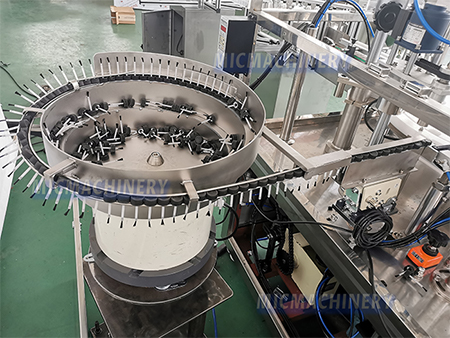

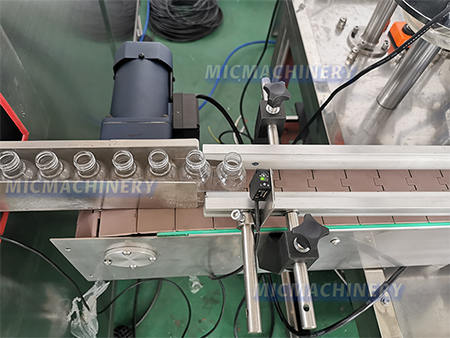

2.Automatic Nail Polish Filling Machines: These machines are designed for high-volume production and feature full automation, from filling to capping. They offer advanced control systems for precise volume measurement and often include touchscreens for easy adjustments. Automatic machines are ideal for businesses looking to scale up quickly.

3.Semi-Automatic Machines: For smaller operations, semi-automatic nail polish filling machines offer a more affordable solution while still improving efficiency over manual processes. These systems require some level of human input but still provide a significant boost in precision and speed.

The Benefits of Using an Automatic Nail Polish Filling Machine

◈ Increased Production Speed: Automated filling machines work much faster than manual processes, allowing businesses to meet higher demand without compromising quality.

◈ Consistent Quality: Precision filling ensures that each bottle contains the same amount of nail polish, reducing waste and improving customer satisfaction.

◈ Reduced Labor Costs: Automation minimizes the need for manual labor, allowing your workforce to focus on other tasks while the machine handles the filling and capping.◈ Enhanced Hygiene: With fewer human interactions, the risk of contamination is significantly reduced, ensuring that your product meets the highest hygiene standards.

◈ Cost Efficiency: While the initial investment in an automatic machine may be higher, the long-term savings in labor costs and increased production efficiency can make it a worthwhile investment.

Key Features of Nail Polish Filling Machines

☑ Precision Filling: Automatic machines can be calibrated to fill bottles with a high degree of accuracy, ensuring that the correct volume is dispensed every time.

☑ Versatility: Machines can be adjusted to accommodate different bottle sizes, making them ideal for companies that produce a range of nail polish products.

☑ Advanced Control Systems: Many machines come equipped with advanced software that allows users to monitor and adjust key parameters, such as fill levels, temperature, and speed, in real-time.

☑ Capping Mechanisms: The capping feature ensures that each bottle is sealed tightly, preventing leaks and ensuring product integrity during shipping.

☑ User-Friendly Interfaces: Many models come with intuitive touchscreen controls, making it easy for operators to set up and adjust the machine to meet production needs.

How to Choose the Right Nail Polish Filling Machine for Your Business

◈ Production Volume: High-volume operations will benefit from automatic systems, while smaller operations may find semi-automatic machines more suitable.

◈ Customization: Some machines offer custom configurations to accommodate unique bottle shapes or sizes, so be sure to check for compatibility with your packaging.

◈ Budget: While automatic machines offer the most efficiency, semi-automatic machines are a more affordable option for smaller businesses or those with lower production volumes.

◈ Maintenance and Support: Opt for machines from reputable manufacturers that offer robust after-sales support and easy access to spare parts.

The Role of Technology in Nail Polish Filling Machines

· Touchscreen Controls: These intuitive interfaces make it easy for operators to monitor and adjust the filling process, increasing flexibility and efficiency.

· Automation Integration: Some machines can be integrated with other parts of the production line, such as labeling or packaging systems, further streamlining the process.

· Real-Time Monitoring: Advanced machines offer real-time data on performance metrics, such as fill volume and production speed, helping businesses optimize their processes.

Common Applications of Nail Polish Filling Machines

Nail polish filling machines are used in various applications, including:

◈ Mass Production: Large factories producing thousands of bottles per day rely on automated systems to keep up with demand and maintain consistency.

◈ Small Batch Manufacturing: For smaller companies or artisan nail polish brands, filling machines allow for faster production without compromising on quality.◈ Private Labeling: Manufacturers who produce nail polish for other brands can use filling machines to create customized products with ease.

Maintenance and Troubleshooting for Nail Polish Filling Machines

◈ Routine Cleaning: Regular cleaning helps prevent the buildup of residue and ensures the machine continues to function properly.

◈ Lubrication: Periodic lubrication of moving parts helps reduce wear and tear and ensures smooth operation.

◈ Troubleshooting: Common issues include clogging, under-filling, or misalignment. These can often be resolved by adjusting the settings or contacting the manufacturer for support.

◈ Regular Servicing: Schedule professional servicing at regular intervals to keep the machine in optimal condition.

Future Trends in Nail Polish Filling Technology

◈ Smarter Automation: Even more sophisticated machines with artificial intelligence (AI) capabilities that can learn and adapt to changing production conditions.

◈ Sustainability: More eco-friendly machines and packaging options, in line with the growing demand for sustainable products in the beauty industry.

◈ Faster Production Speeds: As technology evolves, filling machines will become even faster and more efficient, meeting the increasing demands of the nail polish market.

More Model And Speed Click

|

Model |

||

|

Filling Volume Range |

5-20ml |

10ml-5000ml |

|

Production Speed |

20-30 bottles/min |

1-50 bottles/min |

|

Power |

2.5Kw |

220W |

|

Air Pressure |

0.6-0.8Mpa |

0.4-0.6MPa |

|

Weight |

500kg |

60 kg |

|

Dimension (L×W×H) |

2000×1000×1800mm |

500×580×1380mm |

|

Applications |

Nail Polish |

Sauce, Water,Nail Polish,etc. |