Advanced Perfume Filling Machines for Modern Brands

2025-05-09

Advanced Perfume Filling Machines for Modern Brands

Meeting the Rising Demand for Precision in Perfume Production

As global demand for luxury and niche perfumes continues to rise, fragrance manufacturers are under pressure to deliver both quality and volume efficiently. Consumers expect consistency in scent and packaging—every single time.

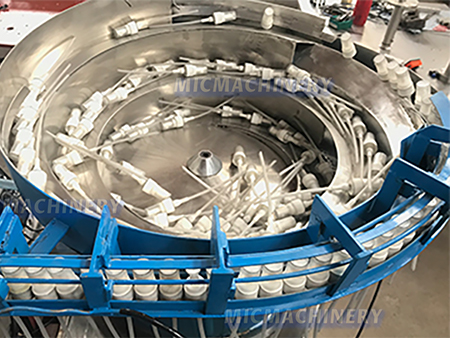

This demand has led to widespread adoption of the liquid filling machine for perfume. These machines are engineered to deliver high-precision dosing while minimizing product waste, making them essential for both sustainability and profitability.

This demand has led to widespread adoption of the liquid filling machine for perfume. These machines are engineered to deliver high-precision dosing while minimizing product waste, making them essential for both sustainability and profitability.

Small-scale artisan producers benefit from semi-automatic machines that allow flexibility and control. In contrast, large corporations invest in fully automated systems to handle mass production with unmatched accuracy and speed.

Innovation in Filling Technology: Smart, Sleek, and Scalable

Today’s liquid filling machine for perfume isn’t just about functionality—it’s about adaptability. With modular setups and touchscreen interfaces, these machines allow quick format changes and easy operation, even for less-experienced technicians.

One standout feature is IoT connectivity. Machines equipped with smart diagnostics can detect faults in real-time, schedule maintenance alerts, and optimize performance data—keeping downtime to a minimum.

Flexibility is key in the beauty industry. Modern systems can easily switch between 30ml tester bottles and 100ml signature editions. Whether you’re working with glass or recyclable PET, these machines deliver consistency without needing separate lines.

This scalability means you can expand your product line without investing in entirely new machinery—a crucial advantage in today’s fast-moving market.

One standout feature is IoT connectivity. Machines equipped with smart diagnostics can detect faults in real-time, schedule maintenance alerts, and optimize performance data—keeping downtime to a minimum.

Flexibility is key in the beauty industry. Modern systems can easily switch between 30ml tester bottles and 100ml signature editions. Whether you’re working with glass or recyclable PET, these machines deliver consistency without needing separate lines.

This scalability means you can expand your product line without investing in entirely new machinery—a crucial advantage in today’s fast-moving market.

Seamless Integration with Advanced Bottle Capping

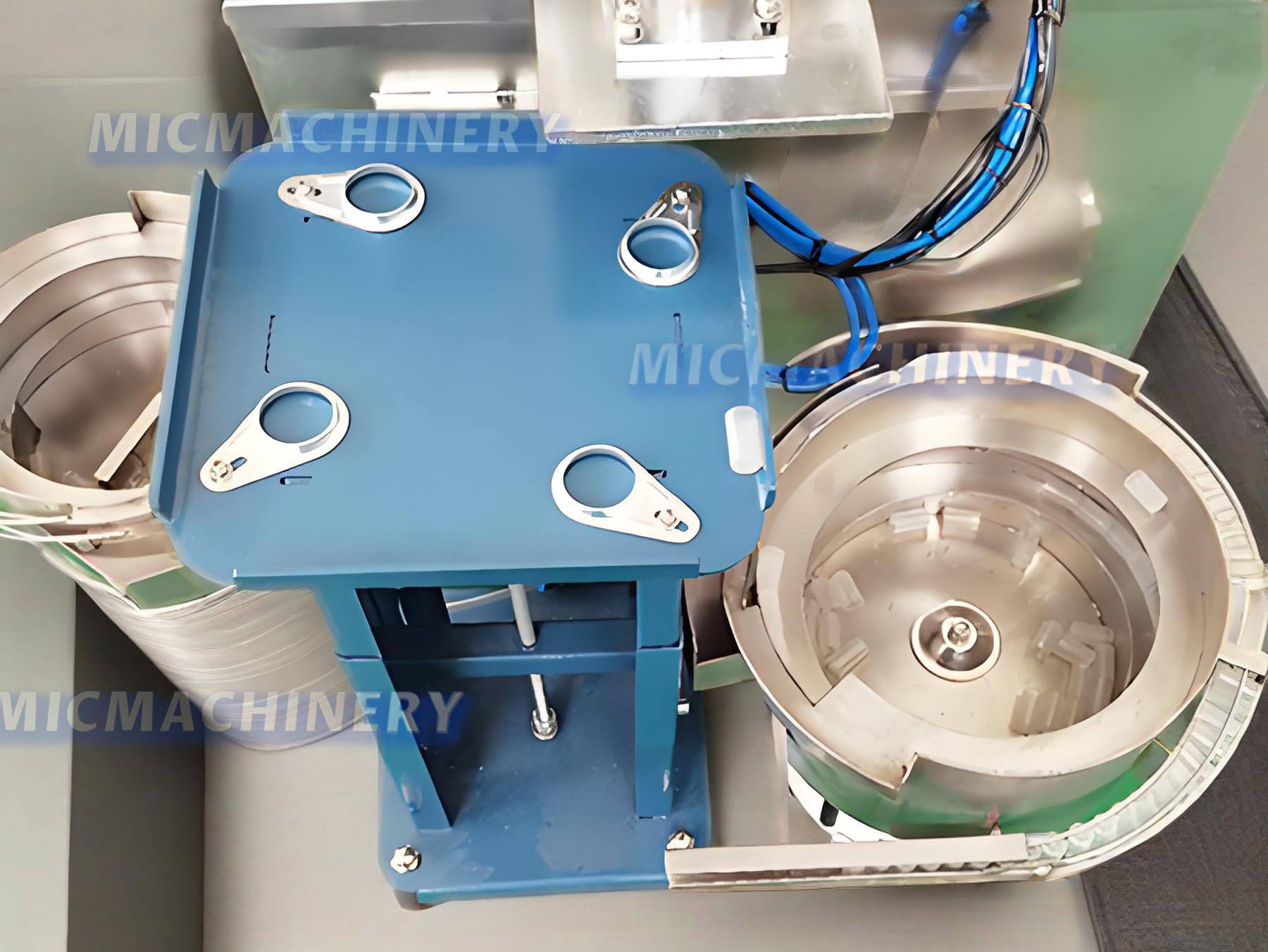

Once a bottle is filled with precision, the next step is secure sealing. A high-performance perfume bottle capping machine ensures that every bottle is closed tightly—preserving scent integrity and enhancing shelf appeal.

These machines handle a variety of cap styles: crimp caps for traditional looks, screw caps for modern packaging, and snap-ons for refillable containers. With adjustable torque and automated alignment, capping becomes a flawless process.

Integration with the filling machine ensures perfect synchronization. Bottles are filled and capped in a single streamlined flow, eliminating manual errors and significantly increasing throughput.

These machines handle a variety of cap styles: crimp caps for traditional looks, screw caps for modern packaging, and snap-ons for refillable containers. With adjustable torque and automated alignment, capping becomes a flawless process.

Integration with the filling machine ensures perfect synchronization. Bottles are filled and capped in a single streamlined flow, eliminating manual errors and significantly increasing throughput.

Choosing the Right Perfume Filling Machine Manufacturer

Your choice of supplier can directly influence your productivity, operational safety, and brand consistency.

An experienced manufacturer will understand the unique needs of perfume bottling—from viscosity variance to the importance of aesthetic presentation. They’ll provide machines tailored to specific bottle shapes, volumes, and closure mechanisms.

In addition, top-tier manufacturers assist in GMP compliance, CE certifications, and environmental audits—so your machinery isn’t just high-performing, but also globally compliant and future-ready.

An experienced manufacturer will understand the unique needs of perfume bottling—from viscosity variance to the importance of aesthetic presentation. They’ll provide machines tailored to specific bottle shapes, volumes, and closure mechanisms.

In addition, top-tier manufacturers assist in GMP compliance, CE certifications, and environmental audits—so your machinery isn’t just high-performing, but also globally compliant and future-ready.

Aligning with Global Trends in Beauty Manufacturing

The rise of clean beauty and ethical branding has changed how perfumes are manufactured and packaged. Automation now plays a key role in aligning production with environmental and social expectations.

Using a liquid filling machine for perfume reduces spillage and overfilling, helping minimize fragrance waste and cut material usage. These small gains can significantly impact sustainability scores for eco-conscious brands.

Consumer expectations have also shifted toward visual perfection. The perfume bottle capping machine ensures not only a tight seal but also perfect cap orientation and presentation—vital for luxury shelf impact.

Automation supports all these goals by enabling consistency, reducing labor needs, and ensuring traceability at every stage of production.

Using a liquid filling machine for perfume reduces spillage and overfilling, helping minimize fragrance waste and cut material usage. These small gains can significantly impact sustainability scores for eco-conscious brands.

Consumer expectations have also shifted toward visual perfection. The perfume bottle capping machine ensures not only a tight seal but also perfect cap orientation and presentation—vital for luxury shelf impact.

Automation supports all these goals by enabling consistency, reducing labor needs, and ensuring traceability at every stage of production.

Why Invest Now: Long-Term Value and Brand Growth

A perfume filling machine is more than just a production tool—it's a brand investment. As trends shift faster than ever, having adaptable, reliable, and tech-ready equipment is essential.

By choosing a trusted perfume filling machine manufacturer, you secure a partner that evolves with your business—offering upgrades, modular expansions, and tailored solutions.

By choosing a trusted perfume filling machine manufacturer, you secure a partner that evolves with your business—offering upgrades, modular expansions, and tailored solutions.

Our equipment range includes the latest liquid filling machine for perfume and perfume bottle capping machine systems. With advanced automation and a focus on precision, we help clients around the world streamline operations and grow their fragrance lines with confidence.

Whether you're launching a new line or scaling up production, now is the time to adopt filling and capping solutions that combine speed, flexibility, and industry-leading precision.

Whether you're launching a new line or scaling up production, now is the time to adopt filling and capping solutions that combine speed, flexibility, and industry-leading precision.

Ready to upgrade your filling line?

Interested in learning more? Contact our team today and discover how our perfume filling and capping systems can transform your production.