- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

Product Characteristics:

The Automatic Detergent Filling Machine boasts a range of exceptional characteristics meticulously engineered for efficiency and precision. Crafted from durable materials, often stainless steel, these machines ensure longevity while maintaining the highest standards of quality and hygiene. Featuring automated container feeding, precise filling, and capping mechanisms, they epitomize the perfect blend of speed and accuracy in liquid product manufacturing. User-friendly interfaces with programmable controls accommodate various container sizes and formulations, ensuring each product receives a consistent and precise fill. Equipped with anti-spill features and precise dosing capabilities, these machines preserve the integrity of liquid detergent formulations, delivering products that resonate with both efficiency and the promise of optimal cleaning performance.

Product Applications:

The applications of the Automatic Detergent Filling Machine span the entire spectrum of cleaning product manufacturing, providing a comprehensive solution for efficient and automated filling of liquid detergents. Whether producing standard laundry detergents, dishwashing liquids, or specialized cleaning formulations, these machines ensure uniformity in dosage and presentation. The adaptability of the Automatic Detergent Filling Machine caters to the dynamic requirements of the cleaning product industry, where each liquid detergent requires a tailored approach to dispensing, capping, and preserving its unique formula.

Mechanical Principle:

At its core, the Automatic Detergent Filling Machine operates on advanced mechanical principles designed for speed, precision, and automation. Utilizing liquid feeding systems, dosing pumps, and filling nozzles, the machine accurately measures and dispenses the specified quantity of detergent into individual containers. Automated capping mechanisms secure the containers, preserving the freshness and effectiveness of the liquid detergent. Integrated sensors and programmable logic controllers (PLCs) oversee the entire process, ensuring uniformity, minimizing errors, and enhancing the overall efficiency of automatic detergent filling operations.

In conclusion, the Automatic Detergent Filling Machine stands as a symbol of manufacturing prowess in the cleaning product industry. Its exceptional product characteristics, diverse applications, and advanced mechanical principles make it an indispensable asset for manufacturers globally. Embracing cutting-edge technology, this machine not only ensures the speed and precision of detergent filling but also upholds the highest standards of presentation, consistency, and quality. As a fundamental component in various production workflows, it continues to shape the way liquid cleaning products are filled, ensuring each container embodies the essence of automation and the promise of optimal cleaning performance.

Filling head

The detergent is put into the material cylinder, and the piston to pump the detergent into the measuring cylinder. Then the piston moves up to send the detergent to the filling pipe. At the same time, when the bottle enters the filling machine through the conveyor belt, the filling head moves down to start filling. After filling, the conveyor belt will automatically send the bottle to the capping station.

(Filling process without drip leakage, the number of filling head can be customized according to your needs and diameter of filling head basis on the diameter of your barrel’s mouth)

The three-way valve and Measuring cylinder

The three-way valve is controlled by PLC system, The three-way valve rotates internally to adjust the connection between the material box and the measuring cylinder cylinder or the measuring cylinder cylinder and the filling pipe. Accordingly it controls the movement of materials from the material tank to the dosing cylinder and then to the filling pipe.

Measuring the effect of cylinder is primarily a quantitative filling, it allows you to have higher filling accuracy,

Main working process: downward movement of the piston to fill the material from the material cylinder to the measuring cylinder, and then controls the upward movement of the piston to send the material to the filling pipe and start filling.

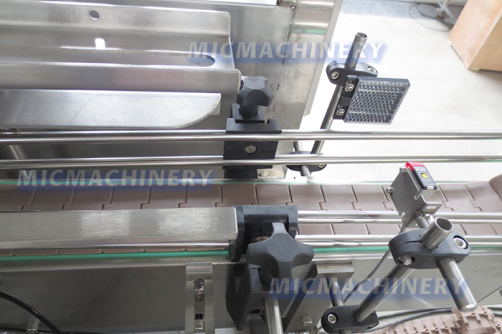

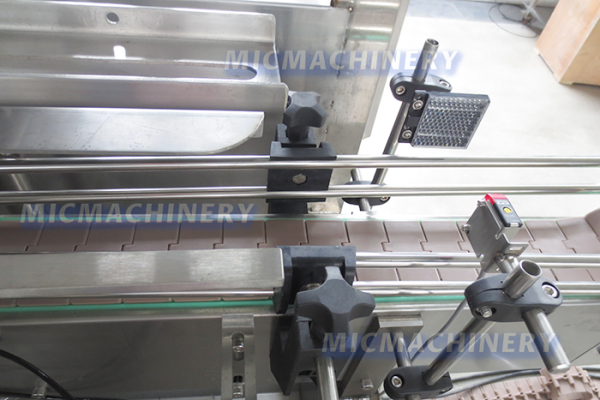

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of bottle,The width between the two pipes can be adjusted according to your container,ensure smooth bottle safely from the conveyor belt moved .On the side of the conveyor is equipped with sensors that can automatically identify when the bottle to go out or, in order to send signals to filling station of screw cap.

PLC programming control, with a touch screen and man-machine interface system;automatic bottle feeding, automatic filling, automatic bottle;the servo motor drive, double screw drive, the control piston rod movement to ensure the filling stability, filling accuracy higher.

It can be with the capping machine, labeling machine supporting the formation of water production line. It integrates light, machine, electricity and gas into one body. Is an easy to operate filling machine. With stable and reliable operation, high production efficiency, strong adaptability.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |