- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the dynamic landscape of manufacturing, the Laundry Detergent Filling Machine(Detergent Packing Machine) stands as a beacon of efficiency, seamlessly integrating technological innovation with the demands of the cleaning product industry. This advanced machine plays a pivotal role in ensuring the precise and rapid filling of laundry detergent, catering to the diverse needs of manufacturers. As we explore its distinctive product characteristics, varied applications, and the intricate mechanical principles guiding its operation, we embark on a journey to unveil the essence of excellence in laundry detergent filling. From liquid detergents to fabric softeners, this machine ensures each bottle is filled with accuracy, consistency, and the promise of optimal cleaning efficacy.

Product Characteristics:

The Laundry Detergent Filling Machine(Detergent Packing Machine) boasts an array of exceptional characteristics meticulously engineered for accuracy and efficiency. Crafted from durable materials, often stainless steel, these machines ensure longevity while maintaining the highest standards of quality and hygiene. Featuring automated bottle feeding, precise filling, and capping mechanisms, they strike a delicate balance between automation and the intricacies of liquid product manufacturing. User-friendly interfaces with adjustable controls accommodate various bottle sizes and formulations, ensuring each product receives a consistent and accurate fill. Equipped with anti-spill features and precise dosing capabilities, these machines preserve the integrity of liquid detergent formulations, delivering products that resonate with both quality and the promise of optimal cleaning performance.

Product Applications:

The applications of the Laundry Detergent Filling Machine span the entire spectrum of cleaning product manufacturing, providing a comprehensive solution for efficient and precise filling of liquid detergents. Whether producing standard laundry detergents, specialized fabric softeners, or stain removers, these machines ensure uniformity in dosage and presentation. The adaptability of the Laundry Detergent Filling Machine caters to the dynamic requirements of the cleaning product industry, where each liquid detergent requires a tailored approach to dispensing, capping, and preserving its unique formula.

Mechanical Principle:

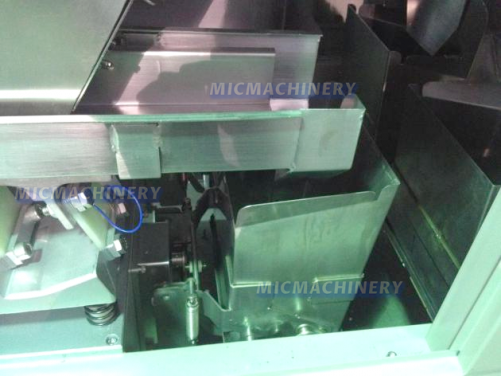

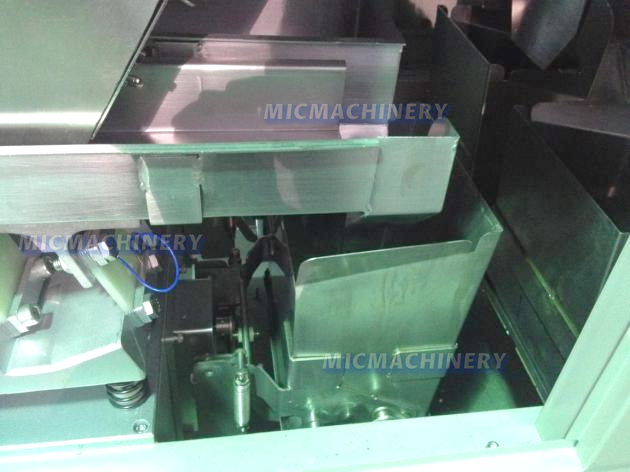

At its core, the Laundry Detergent Filling Machine operates on advanced mechanical principles designed for delicacy, speed, and precision. Utilizing liquid feeding systems, dosing pumps, and filling nozzles, the machine accurately measures and dispenses the specified quantity of detergent into individual containers. Capping mechanisms, often employing high-speed technology, secure the containers, preserving the freshness and effectiveness of the liquid detergent. Integrated sensors and programmable logic controllers (PLCs) oversee the entire process, ensuring uniformity, minimizing errors, and enhancing the overall efficiency of laundry detergent filling operations.

In conclusion, the Laundry Detergent Filling Machine stands as a symbol of precision in the cleaning product industry. Its exceptional product characteristics, diverse applications, and advanced mechanical principles make it an indispensable asset for manufacturers globally. Embracing cutting-edge technology, this machine not only ensures the accuracy of laundry detergent filling but also upholds the highest standards of presentation, consistency, and quality. As a fundamental component in various production workflows, it continues to shape the way liquid cleaning products are filled, ensuring each bottle embodies the essence of precision and the promise of optimal cleaning performance.

Four-heads electronic weighing machine

The mechanical structure of the electronic weighing machine is composed of the bin, feeder, vibrator, weighing hopper, motor bucket opening mechanism, reset switch and other structures. The weighing hopper is equipped with a load sensor, and the vibrator drives the feeder to feed the weighing hopper. When the feeding amount reaches the preset weight, the feeder stops feeding and the weighing hopper opens the door to put the material into the bag.

Weighing hopper

The plate spring blade made of imported carbon fiber composite material is stable and reliable, with low power consumption of 40W coil and IP32 waterproof grade, which can effectively guarantee the accuracy of weighing process.

Feeder

The angular design of the feeder can effectively solve the influence of the change of the material layer on the vibrating feeder and ensure the stability of the weighing in the continuous production.

Vibrating feeder

Weighing hopper and sensor integration to improve the equipment level of dust, scale for fighting with self-locking doumen, stepping motor drive, cancelled the rocker mechanism, weighing hopper more convenient removal, scale bucket volume on the basis of the original equipment increased 1 l, measurement according to observe the door to the removable type, without a hinge, organic glass tempered glass instead.

ZH-100 model packing machine is a new product developed by our company, which has the advantages of small volume, light weight, wide application range and high production efficiency. At the same time, the machine can be used in line with the production line of vertical bag-making and packing machine to achieve the best effect and meet the requirements of the national food and drug production quality management standard -- "GMP".

二、Characteristics and Applications

1、ZH-100 Box Packing Machine Can reliably pack all kinds of granule, powder and other materials and some packaging bags into the carton with specific specifications, and seal the carton and send it out. Is suitable for all kinds of food packaging, chemical packaging, pet food packaging and the packing of the agricultural products, using a wide range, according to the different requirements of users at the same time, can change the packing products on a regular basis, and the mold production cycle is short, easy assembly and debugging, which is applicable to the production of large quantities of single variety, at the same time can satisfy users of different types of small batch production。

This machine has these features as below:

1.Electronic packaging speed control system;

2.Package weight or volume can be adjusted automatically;The package size is adjustable;

3.Special mechanism with dust removal tube, vibration for some packaging materials;

4.Electronically controlled dispensing glue system。Top and bottom spray guns, each spray gun has several nozzle;

5.Reliable fault protection system。

二、Main machine mechanism and working principle (See attached photo1)

1. This machine adopts a series of complex transmission, mimicking human action to automatically complete the box taking, opening, folding, filling, sealing and other procedures of the machine's work flow is as follows。

2. The vacuum used in this machine is produced by vacuum pump。

3. The cartons are placed manually in a box library with a capacity of 800-1000 cartons. The paper box detection photoelectric sensor S0 sends signals to the PLC, which controls the feeding cylinder solenoid valve and drives the cylinder to ensure the box supply. Under the joint action of compressed air and vacuum, the cartridge sucker is taken to absorb the carton and sent to the mold box of the main frame by the transmission mechanism. At this time, the cartridge sucker is taken to loosen the carton, and the carton plate is tapped into the mold box to unfold and shape。

4. The carton enters the subsequent packaging process. The photoelectric sensor S1 detects the box signal, and the hot melt adhesive machine is prepared. When the box mouth does not enter the box mouth guide groove correctly, the photoelectric sensor S2 and S3 send signals to PLC, and THE PLC interrupts the operation of the host machine. After the lower box mouth is folded, the hot melt adhesive machine is sprayed to seal the box, and the roller compacting the seal. The photoelectric sensor S4 on the host frame detects a box signal, and PLC will send the signal to the weighing scale, which will make the cutting preparation。

5. When the paper box enters the cutting station, the rotating bin opens under the action of CAM and puts the material into the paper box. At the bottom of the rotating bin, a vibrating platform is installed to vibrate the material when the paper box containing the material passes by。

6. After vibration, the packaging process is the same as that of the lower box mouth. The upper box mouth is folded, the box is sprayed with glue and sealed, and the packing is compacted and sealed. After completion, the finished product is pushed to the conveyor by the pushing box mechanism. This completes all the packaging processes。

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback: