- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the vibrant world of culinary creations, precision meets flavor with the Sauce Bottle Filler, a marvel of innovation reshaping the way sauces are bottled and enjoyed. This cutting-edge equipment seamlessly blends the essence of sauces with advanced automation, ensuring consistency and quality in every pour. By exploring its distinct product characteristics, diverse applications, and the intricate mechanical principles guiding its operation, we delve into the essence of culinary excellence. From artisanal sauce artisans to large-scale manufacturers and commercial kitchens, the Sauce Bottle Filler revolutionizes the bottling process, promising not just sauces, but experiences.

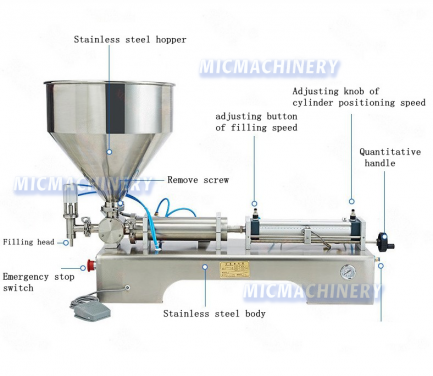

Product Characteristics:

The Sauce Bottle Filler boasts exceptional product characteristics designed for precision and efficiency. Crafted from high-grade stainless steel and compliant with stringent food safety standards, these fillers guarantee durability and hygiene. Featuring specialized dosing systems and adjustable filling heads, they accommodate a variety of sauce viscosities, from thin dressings to thick marinades, ensuring uniformity in every bottle. Enhanced with advanced sensors and intuitive control interfaces, these fillers minimize spillage, optimize resource utilization, and maintain cleanliness. Equipped with anti-leak features and tamper-evident seals, the packaging integrity is preserved, delivering a premium product to consumers.

Product Applications:

The applications of the Sauce Bottle Filler are as diverse as the sauces it encapsulates. Artisanal sauce makers rely on these machines to preserve homemade flavors and maintain authenticity, ensuring precise portions in each bottle. Large-scale manufacturers utilize this equipment for efficient bulk production, meeting the demands of retail, hospitality, and food service sectors with consistent quality. Restaurants, fast-food chains, and gourmet kitchens benefit from the precision of these fillers, ensuring uniformity in recipes and enhancing the presentation of signature dishes. Moreover, specialty stores and online retailers leverage this technology to offer customers a range of sauces, from classic to exotic, enhancing culinary adventures with every taste.

Mechanical Principle:

At its core, the Sauce Bottle Filler operates on advanced mechanical principles for speed, accuracy, and reliability. Utilizing precision dosing pumps, conveyor systems, and filling nozzles, the filler accurately measures and dispenses the specified quantity of sauce into individual bottles. Sealing mechanisms, employing high-speed capping or sealing technology, secure the packaging, preserving freshness and flavor. Integrated sensors and programmable logic controllers (PLCs) oversee the process, ensuring uniformity, minimizing errors, and enhancing overall efficiency in the filling and sealing operations.

In conclusion, the Sauce Bottle Filler is a testament to culinary precision, enhancing the sauce bottling process to match the creativity of chefs and the expectations of consumers. Its exceptional characteristics, diverse applications, and advanced mechanical principles make it indispensable for the culinary industry, shaping the way sauces are bottled, served, and savored. As an essential tool for both artisanal creators and commercial enterprises, it continues to elevate culinary experiences, ensuring that each sauce, each pour, embodies the essence of flavor and quality.

Filling Head

when the bottle comes under the filling head, cylinder head began to move down the drive filling, filling process without dripping, do not waste material, also can ensure the bottle clean and tidy.

The size of the filling head can be customized according to the caliber of the bottle, ensuring that this machine is absolutely suitable for your product

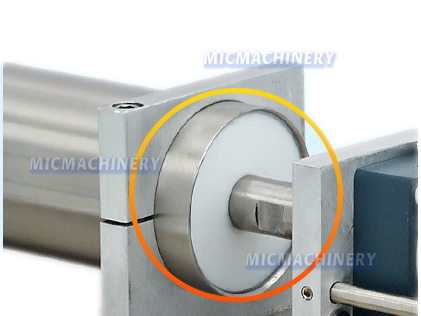

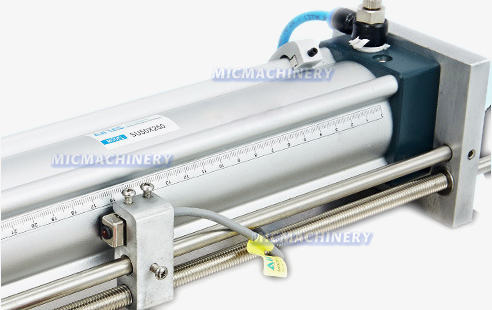

Air Cylinder

The cylinder is through the internal pumping system, the material out from the material cylinder, and then in the filling. Driven by electricity and air compressor.The machine is all made of SUS304. Corrosion-resistant, compact structure, easy to operate, beautiful appearance, in line with GMP standards.

2. Filling volume can be easily adjusted.

3. The machine is all made of SUS304. Corrosion-resistant, compact structure, easy to operate, beautiful appearance, in line with GMP standards.

4. It can work automatically or controlled by a operation pedal.

5. Has single head, double heads and full pneumatic model. Our machine support special customization.

6. It is suitable for filling liquid and paste materials such as water, juice, oil, sauce, toothpaste, cosmetic cream, hand cream, honey, peanut butter etc. lt is widely used in chemical industry, food, cosmetic, medicine, etc.

if you want to know more models of filling machine, you can refer to the table below

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

In addition to,we have hot sauce bottle filler,sauce bottle filler,bbq sauce bottle filler. If you are more than interested in the machine ,you can contact us at market@micmachinery.com

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback:

- MIC Mayonnaise Filling Machine ( Mayonnaise, Sauce, Yogurt, 30-35 Cups/min )

- MIC-ZF20 Hot Sauce Bottle Filler ( Sauce, Oil, Honey, 4000 Bottles/h )

- MIC-ZF8 Mayonnaise Bottle Filling Machine ( Oil, Sauce, Cream, 1800 Bottles/h )

- MIC Tracking Type Mayonnaise Filling Machine ( Chili Sauce, Oil, Paste, 3000-3600 Bottles/H )

- MIC Mayonnaise Packing Machine ( Sauce, Ketchup, Honey, 20-40 Sachet/min )

- MIC-V01 Sauce Bottle Filler ( Honey, Liquid, Ketchup, 1500 Bottles/h )