- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

The 8 heads mayonnaise bottle filling machine represents a leap forward in food packaging technology, specifically designed to meet the high standards required for mayonnaise production. This machine's performance is distinguished by its efficiency, precision, and adaptability, making it an invaluable tool for manufacturers aiming to optimize their mayonnaise bottling process.

Performance and Efficiency

The mayonnaise bottle filling machine is engineered to handle high-volume production with remarkable efficiency. Its eight filling heads operate simultaneously, significantly increasing the throughput and reducing bottling time. This level of automation minimizes manual intervention, streamlining the entire production line and ensuring a smooth, continuous operation.

Precision and Accuracy

Accuracy is paramount in the food industry, and the mayonnaise filling machine excels in delivering precise fill volumes for each bottle. It utilizes advanced volumetric or gravimetric filling technologies to ensure that each bottle contains the exact amount of mayonnaise, reducing product waste and ensuring consistency across all bottles. This high level of precision not only maintains product quality but also enhances customer satisfaction.

Versatility and Adaptability

The mayonnaise packing machine is highly versatile, capable of accommodating various bottle sizes and shapes. It can be easily adjusted to handle different production requirements, making it suitable for a range of mayonnaise packaging needs. Whether dealing with small condiment bottles or larger bulk containers, this machine offers the flexibility needed to meet diverse market demands.

Key Features

High-Speed Operation: The eight filling heads work in unison to fill multiple bottles simultaneously, greatly enhancing production speed.

Precision Filling: Advanced technology ensures accurate fill levels, maintaining consistency and quality in every bottle.

User-Friendly Interface: Intuitive controls allow operators to easily set parameters and monitor the filling process, reducing the learning curve and operational complexity.

Durable Construction: Built with high-quality materials, the machine is designed for durability and reliable performance under continuous use.

Easy Maintenance: The machine's design facilitates straightforward cleaning and maintenance, minimizing downtime and operational costs.

The 8 heads mayonnaise bottle filling machine is ideal for filling various types of mayonnaise, including:

Traditional mayonnaise

Flavored mayonnaise variants

Low-fat and diet mayonnaise

Investing in an 8 heads mayonnaise bottle filling machine can transform the bottling process for mayonnaise manufacturers, offering enhanced efficiency, precision, and versatility. By ensuring consistent and accurate filling, this machine helps maintain product quality, achieve production targets, and ultimately, satisfy customer demands. Whether you are looking to improve small-scale mayonnaise bottling operations or enhance a large production line, the mayonnaise bottle filling machine is an essential tool for modern food packaging.

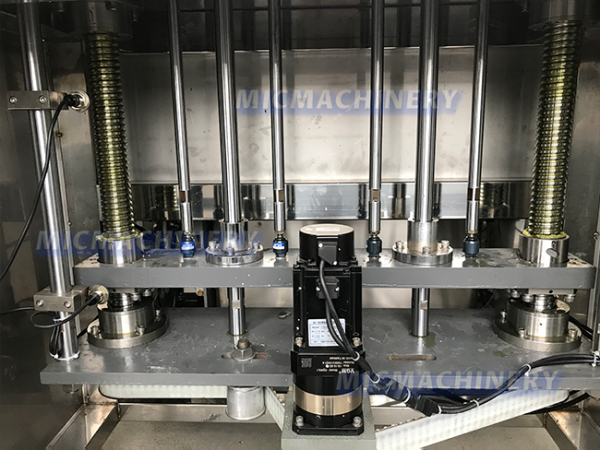

Filling head

The oil is put into the material cylinder, the piston to pump the oil into the measuring cylinder. Then the piston moves up to send the oil to the filling pipe. At the same time, when the bottle enters the filling machine through the conveyor belt, the filling head moves down to start filling. After filling, the conveyor belt will automatically send the bottle to the capping station.

(Filling process without drip leakage, the number of filling head can be customized according to your needs and diameter of filling head basis on the diameter of your barrel’s mouth)

Servo motor

This filling machine adopts servo motor drive, servo motor high efficiency, small volume and relatively high power, can drive the machine more stable, smooth filling.

In addition, the servo motor operation noise is small, will not cause too much noise burden to the workshop.

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of bottle,The width between the two pipes can be adjusted according to your container,ensure smooth bottle safely from the conveyor belt moved .

On the side of the conveyor is equipped with sensors that can automatically identify when the bottle to go out or, in order to send signals to filling station of screw cap.

1. Adopt PLC programmable control system with touch screen interface.

2. Automatic bottle feeding, automatic filling, automatic bottle.

3. Adopt servo motor drive, double screw-rod drive, Control the movement of the piston rod to ensure the stability of the filling.

4. Adopt double-ball screw rod filling the filling nozzle dive

5. It can be used with capping machine, labeling machine supporting the formation of the production line

6. It combines optical, mechanical, electrical, gas in one. It is easy to operate a filling machine.

7. Having a stable and reliable operation, high production efficiency, strong adaptability.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

Mic 18-4 |

MIC-18-6 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

vegetable oil , cooking oil , olive oil, edible oil, sunflower oil, peanut oil etc liquid like oil products, Sauce, Ketchup, Syrup, Detergent, Honey, Shampoo, Lotion, Lubricant oil, etc. |

|||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle ,Plastic Bottle Etc |

|||||||

|

Speed (basis on 50-5000ml) |

1800-2200B/H |

2000-6000B/H |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML,0.5-2L.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

|||||||

|

Power |

1.5Kw |

3Kw |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

2570*2300*2650 mm |

2400*1400*2500 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

5000Kg |

2500kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

In addition to,we have oil filling machine,edible oil filling machine,olive oil filling machine,cooking oil filling machine,vegetable oil filling machine,olive oil bottling machine,sunflower oil filling machine.

If you are more than interested in the machine ,you can contact us at market@micmachinery.com

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

Filling head

8 heads

Filling volume range

50-1000ml(Use 1000ml piston cylinder)

Production speed

≤1800 Bph basis on 1000ml bottle

Voltage

220v/380v

Power

3kw

Suitable bottle’s diameter

Ф40mm-Ф100mm

Filling error

≤±1

Work pressure

0.55Mpa-0.65Mpa

Size

2000mm × 1400mm× 2500mm

Weight

1000kg

|

Touch screen |

Canada xinjie color |

|

PLC |

Schneider |

|

Solenoid valve |

Taiwan Airtac |

|

Optoelectronic system |

OPTEX |

|

Micro differential pressure switch |

Netherlands |

|

Servo motor |

Taiwan TECO |

|

Air source treatment |

Taiwan Airtac |

|

Button and low voltage electric appliance |

Schneider |

|

Ball screw |

Taiwan |

|

Reducer |

Taiwan VGM |

|

Switching power supply |

Taiwan meanwell |

|

Material |

Contact with the material parts of the 316 materials, and the rest of the 304 stainless steel |

- MIC Mayonnaise Filling Machine ( Mayonnaise, Sauce, Yogurt, 30-35 Cups/min )

- MIC-ZF20 Hot Sauce Bottle Filler ( Sauce, Oil, Honey, 4000 Bottles/h )

- MIC-ZF8 Mayonnaise Bottle Filling Machine ( Oil, Sauce, Cream, 1800 Bottles/h )

- MIC Tracking Type Mayonnaise Filling Machine ( Chili Sauce, Oil, Paste, 3000-3600 Bottles/H )

- MIC Mayonnaise Packing Machine ( Sauce, Ketchup, Honey, 20-40 Sachet/min )

- MIC-V01 Sauce Bottle Filler ( Honey, Liquid, Ketchup, 1500 Bottles/h )