- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

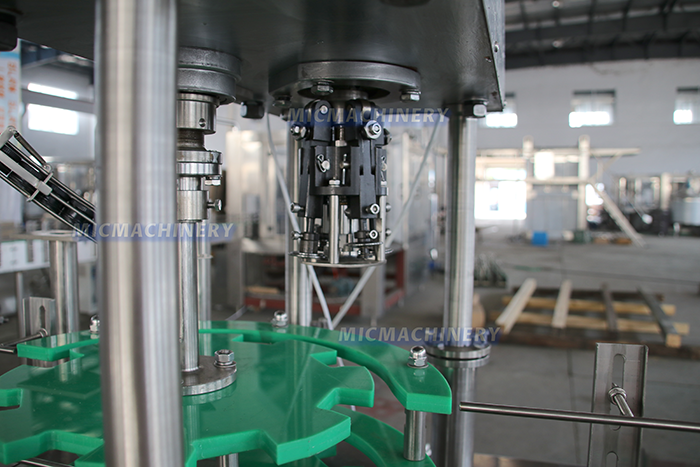

inline filling systems capper: Versatile Solutions for Various Aluminum Cap Sizes

A inline filling systems capper provides versatile and efficient solutions suitable for sealing aluminum caps of various sizes. These machines are essential for industries such as carbonated water, alcohol, fruit juice, health drinks, soy sauce, vinegar, and brewing. The machine’s advanced technology ensures seamless and reliable cap sealing, contributing to the overall product quality and safety.

Key Features and Benefits

Versatility: Designed to accommodate aluminum caps of different sizes, making it a flexible choice for various production needs.

Wide Application: Used in diverse industries including carbonated beverages, alcoholic drinks, fruit juices, health drinks, and condiments like soy sauce and vinegar.

Automation: The machine can automatically convey bottles, align caps, and press them securely, enhancing efficiency and reducing manual labor.

Reliable Performance: Equipped with excellent and reliable pressing technology, ensuring consistent and secure sealing of caps.

Applications

Carbonated Water: Ensures a tight seal to maintain carbonation and prevent leaks.

Alcohol: Provides a secure cap to preserve the integrity and quality of alcoholic beverages.

Fruit Juice: Ensures a hygienic and secure seal, maintaining freshness and preventing contamination.

Health Drinks: Guarantees the safety and quality of health drinks through reliable sealing.

Soy Sauce & Vinegar: Protects the product from spoilage and contamination, ensuring a long shelf life.

Brewing Industry: Ensures the freshness and quality of brewed products through secure sealing.

Advantages

Efficiency: Automating the capping process saves time and labor, increasing overall production efficiency.

Consistency: Reliable pressing technology ensures each cap is sealed uniformly, maintaining product quality.

Safety: Secure sealing prevents contamination and spoilage, ensuring product safety and compliance with industry standards.

By choosing a reputable cap sealing machine supplier, businesses can enhance their production capabilities, ensuring high-quality sealing for a wide range of products. This investment not only improves efficiency but also ensures the safety and integrity of the products, meeting consumer expectations and industry standards.

A inline filling systems capper provides versatile and efficient solutions suitable for sealing aluminum caps of various sizes. These machines are essential for industries such as carbonated water, alcohol, fruit juice, health drinks, soy sauce, vinegar, and brewing. The machine’s advanced technology ensures seamless and reliable cap sealing, contributing to the overall product quality and safety.

Key Features and Benefits

Versatility: Designed to accommodate aluminum caps of different sizes, making it a flexible choice for various production needs.

Wide Application: Used in diverse industries including carbonated beverages, alcoholic drinks, fruit juices, health drinks, and condiments like soy sauce and vinegar.

Automation: The machine can automatically convey bottles, align caps, and press them securely, enhancing efficiency and reducing manual labor.

Reliable Performance: Equipped with excellent and reliable pressing technology, ensuring consistent and secure sealing of caps.

Applications

Carbonated Water: Ensures a tight seal to maintain carbonation and prevent leaks.

Alcohol: Provides a secure cap to preserve the integrity and quality of alcoholic beverages.

Fruit Juice: Ensures a hygienic and secure seal, maintaining freshness and preventing contamination.

Health Drinks: Guarantees the safety and quality of health drinks through reliable sealing.

Soy Sauce & Vinegar: Protects the product from spoilage and contamination, ensuring a long shelf life.

Brewing Industry: Ensures the freshness and quality of brewed products through secure sealing.

Advantages

Efficiency: Automating the capping process saves time and labor, increasing overall production efficiency.

Consistency: Reliable pressing technology ensures each cap is sealed uniformly, maintaining product quality.

Safety: Secure sealing prevents contamination and spoilage, ensuring product safety and compliance with industry standards.

By choosing a reputable cap sealing machine supplier, businesses can enhance their production capabilities, ensuring high-quality sealing for a wide range of products. This investment not only improves efficiency but also ensures the safety and integrity of the products, meeting consumer expectations and industry standards.