- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Semi-Automatic Inline Capping Machine

Mic Machinery proudly presents our semi-automatic Inline Capping Machine, designed for precision, efficiency, and reliability. Ideal for a wide range of industries, this machine ensures consistent capping quality while maintaining operational simplicity, reflecting our commitment to professional manufacturing standards.

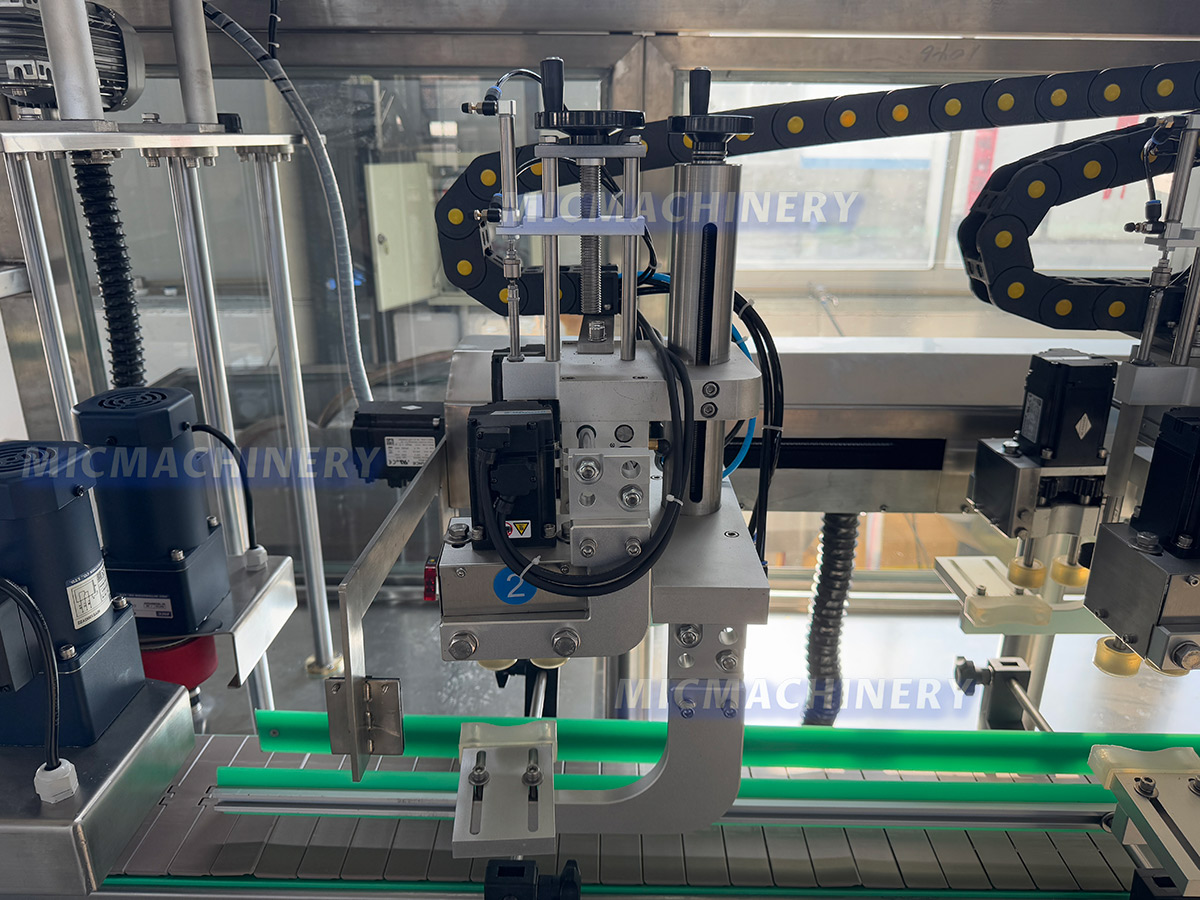

Barometer

The barometer in an Inline Capping Machine monitors the air pressure within the pneumatic system, ensuring consistent torque and stable operation. By providing real-time pressure readings, it helps prevent under- or over-tightening of caps, enhances production accuracy, and maintains smooth, reliable capping performance.

Electric width control

The electric width control in an Inline Capping Machine allows precise adjustment of the conveyor to accommodate different bottle sizes. This feature ensures smooth bottle alignment, reduces jams, and enhances production efficiency by enabling quick, accurate changes without manual intervention.

Lower cover slide rail

The lower cover slide rail in an Inline Capping Machine provides stable guidance for caps during the capping process. It ensures smooth movement, accurate positioning, and consistent alignment, reducing misfeeds or jams while improving overall capping efficiency and maintaining high production quality.

High-Quality Inline Capping Performance

Our Inline Capping Machine is engineered to handle various bottle shapes and sizes with ease. Key features include:

● Adjustable capping heads for different cap types, ensuring secure sealing every time.

● Smooth and stable conveyor integration, reducing bottle tilt or misalignment.

● Durable construction with stainless steel frames for long-term reliability.

This ensures that your production line runs efficiently with minimal downtime, enhancing overall productivity.

Efficient Semi-Automatic Operation

The semi-automatic Inline Capping Machine offers a perfect balance between automation and manual control. Operators can quickly load bottles and monitor the process via the intuitive control panel. Advantages include:

● Easy setup and operation, reducing the learning curve for new staff.

● Customizable capping torque settings to suit different products and cap materials.

This design philosophy emphasizes both precision and flexibility, aligning with Mic Machinery’s professional approach to machinery development.

Versatility and Application

Our Inline Filling Capper is suitable for various industries, including beverages, chemicals, and pharmaceuticals. It supports:

● Bottles made from PET, glass, or HDPE materials.

● Wide-ranging cap designs such as screw caps, flip-top caps, and safety seals.

By accommodating different container and cap specifications, this machine helps businesses expand production capabilities without extensive equipment changes.

Technical Excellence and Reliability

Mic Machinery ensures every Inline Capping Machine meets stringent quality standards. Highlights include:

● High-quality PLC control systems and touch screens for easy monitoring.

● Robust servo-driven capping mechanisms for consistent torque and speed.

● Integrated safety features and sensors to prevent misfeeds or jams.

This focus on technical precision demonstrates our professional dedication to delivering reliable and durable solutions for our clients.

Professional Support and Customization

The semi-automatic Inline Capping Machine and Inline Filling Capper are designed with the user in mind. Mic Machinery offers:

● Customizable configurations based on production line requirements.

● Comprehensive after-sales support including installation guidance and maintenance training.

● Scalable solutions that grow with your business needs.

By combining innovative design, high-quality components, and professional support, Mic Machinery ensures that every capping line achieves maximum efficiency and product safety.

|

Item |

Specification |

|

Number of Capping Heads |

2 heads |

|

Production Speed |

≤6000 bottles/hour (based on 500ml bottles; actual speed depends on cap and bottle type as well as manual cap feeding speed) |

|

Applicable Bottle Size |

Customizable according to bottle samples |

|

Applicable Cap Size |

Customizable according to cap samples |

|

Power Supply |

220V / 380V |

|

Total Power |

4.5 KW |

|

Working Air Pressure |

0.55 Mpa – 0.65 Mpa |

|

Machine Dimensions |

2000 mm × 1100 mm × 1900 mm |

|

Machine Weight |

600 kg |

|

Component |

Brand / Origin |

|

Touch Screen |

Siemens (Germany) |

|

PLC Controller |

Siemens (Germany) |

|

Pneumatic Components |

Airtac (Taiwan) |

|

Frequency Converter |

Schneider (France) |

|

Solenoid Valve |

Airtac (Taiwan) |

|

Air Source Processor |

Airtac (Taiwan) |

|

Servo Motor |

Inovance |

|

Servo Driver |

Inovance |

|

Bottle Detection Photoelectric Sensor |

Optex (Japan) |

|

AC Contactor |

Schneider (France) |

|

Circuit Breaker |

Schneider (France) |

- Semi-Automatic Inline Capping Machine

- inline filling systems capper

- inline chuck capper

- inline capping machine

- inline capper

- in line capper

- inline capping machines

- cap lining machine manufacturer

- automatic inline capping machine

- inline capper machine

- inline filling capper

- inline capping machine factory

- inline capping machine price

- inline capper factory

- inline capper price