- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

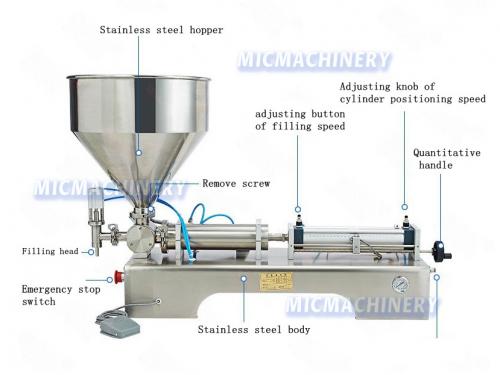

1. Filling with piston pump. Driven by electricity and air compressor.

2. Filling volume can be easily adjusted.

3. The machine is all made of SUS304. Corrosion-resistant, compact structure, easy to operate, beautiful appearance, in line with GMP standards.

4. It can work automatically or controlled by a operation pedal.

5. Has single head, double heads and full pneumatic model. Our machine support special customization.

6. It is suitable for filling liquid and paste materials such as water, juice, oil, sauce, toothpaste, cosmetic cream, hand cream, honey, peanut butter etc. lt is widely used in chemical industry, food, cosmetic, medicine, etc.

Introduction:

In the realm of food packaging, the quest for precision and versatility has led to the evolution of specialized equipment, and at the forefront of this innovation are the hummus bottling machine, hummus filling machine, and hummus packaging machine. Engineered with distinct product characteristics, expansive applications, and a manual mechanical principle, these machines redefine the manual bottling experience for sauces, hummus, and honey, meeting the diverse needs of small-scale producers and artisans in the culinary world.

Product Characteristics:

The manual hummus bottling machine, hummus filling machine, and hummus packaging machine exhibit unique characteristics tailored to the demands of small-scale production. These machines, crafted for ease of use, allow operators to have hands-on control throughout the bottling process. Compact and portable designs make them suitable for limited space, while robust construction ensures durability. Adjustable settings accommodate a variety of bottle sizes, enabling the manual bottling of sauces, hummus, and honey with precision. Additionally, these machines prioritize simplicity, making them accessible to artisanal producers seeking an efficient and manual solution for their bottling needs.

Product Application:

The applications of manual hummus bottling machines extend beyond the singular focus on hummus to encompass a range of liquid delicacies such as sauces and honey. Designed with small-scale producers in mind, these machines offer a flexible solution for bottling various products, facilitating the artisanal touch in packaging. Ideal for farmers' markets, boutique producers, or specialty food establishments, the manual approach allows producers to carefully control the bottling process, ensuring the quality and integrity of their sauces, hummus, and honey in each bottle.

Mechanical Principle:

The manual operation of these machines embodies a straightforward mechanical principle, providing operators with hands-on control. Typically featuring a lever or hand-crank mechanism, these machines enable the manual filling of bottles with sauces, hummus, and honey. The simplicity of the mechanical design ensures ease of operation, making it accessible for small-scale producers without the need for complex automation. The manual control allows producers to adjust filling speeds and volumes according to their preferences, emphasizing the artisanal craftsmanship in the bottling process.

In conclusion, the manual hummus bottling machine, hummus filling machine, and hummus packaging machine redefine the manual bottling experience for small-scale producers, offering a balance of simplicity and precision. With their distinctive product characteristics, versatile applications, and hands-on mechanical principles, these machines empower artisans in the food industry to manually and meticulously fill bottles with the finest sauces, hummus, and honey, adding a personal touch to their craft

if you want to know more models of filling machine, you can refer to the table below

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

in short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Model |

MIC V01 |

|

Voltage |

220V/380V 50/60HZ |

|

Power |

30W |

|

Air Pressure |

0.4-0.6MPa |

|

Filling Speed |

5-25 bottles/min |

|

Filling Accuracy |

±1% |

|

Dimension(L*W*H) |

1000*480*700mm |

|

Filling Range |

10-20ML. 25-250ML. 50-500ML.100-1000ML.250-2500ML. 1000-5000ML |

|

Weight |

35 Kg |

|

Filling Material |

Juice, Oil, Water, Sauce, Toothpaste, Cosmetic Cream, Hand Cream, Honey and etc |

|

Note: If you need special customization. please feel free contact me. |

|

- MIC Hummus Filling Machine ( Mayonnaise, Sauce, Yogurt, 30-35 Cups/Min )

- MIC-ZF20 Hummus Packaging Machine ( Sauce, Oil, Honey, 4000 Bottles/H )

- MIC Tracking Type Hummus Filling Machine ( Chili Sauce, Oil, Paste, 3000-3600 Bottles/H )

- MIC-V01 Hummus Bottling Machine ( Honey, Liquid, Ketchup, 1500 Bottles/H )