- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

In the realm of candle crafting and wax-based creations, the Wax Filling Machine emerges as a cornerstone of precision and efficiency, bringing a seamless blend of technology and artistry to the world of wax filling. This innovative machine seamlessly transforms raw wax into beautifully crafted candles, providing artisans and manufacturers alike with a powerful tool for enhancing production processes. By delving into its unique product characteristics, versatile applications, and the intricate mechanical principles guiding its operation, we unravel the essence of wax filling excellence. From candle-making workshops to industrial-scale production, the Wax Filling Machine ensures each creation embodies the warmth and precision synonymous with quality wax products.

Product Characteristics:

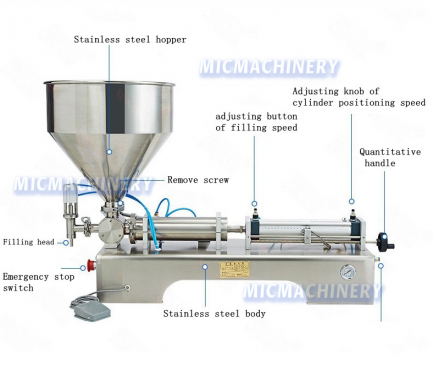

The Wax Filling Machine showcases an array of exceptional characteristics meticulously engineered for precision and ease of use. Crafted from durable materials such as stainless steel, these machines guarantee longevity while maintaining the highest standards of quality. Featuring adjustable wax dosing systems and precision nozzles, they accommodate various candle sizes and shapes, ensuring consistent and accurate filling. Advanced temperature controls and user-friendly interfaces enhance operational efficiency, allowing artisans to achieve the desired texture and finish for their candles. Equipped with anti-drip mechanisms and secure sealing, these machines preserve the integrity of the wax, delivering a product that captivates with its smooth finish and even burn.

Product Applications:

The applications of the Wax Filling Machine span the entire spectrum of candle production, from small artisanal workshops to large-scale manufacturing facilities. Candle makers benefit from the precision of these machines, enabling them to efficiently produce batches of consistent and high-quality candles. Industrial-scale manufacturers utilize Wax Filling Machines for bulk production, ensuring uniformity in size and shape across their product lines. Whether crafting traditional pillar candles, elegant taper candles, or intricate molded designs, these machines cater to the diverse needs of the candle industry, ensuring each creation is a testament to the art of wax filling.

Mechanical Principle:

At its core, the Wax Filling Machine operates on advanced mechanical principles designed for precision and reliability. Utilizing a dosing pump, conveyor systems, and filling nozzles, the machine accurately measures and dispenses the specified quantity of molten wax into individual molds. Temperature controls ensure the wax remains in its optimal state for filling, while integrated sensors and programmable logic controllers (PLCs) oversee the entire process. The precision of the machine guarantees even distribution, minimizing errors and enhancing the overall efficiency of the filling operation.

In conclusion, the Wax Filling Machine stands as a symbol of craftsmanship and efficiency in the world of candle production. Its exceptional product characteristics, versatile applications, and advanced mechanical principles make it an indispensable asset for candle makers and manufacturers globally. Embracing cutting-edge technology, this machine not only ensures the precision of wax filling but also upholds the highest standards of quality and consistency. As a fundamental component in the creation of candles, it continues to shape the way wax products are crafted, ensuring each candle is a masterpiece of warmth, beauty, and precision.

Filling Head

When the bottle comes under the filling head, cylinder head began to move down the drive filling, filling process without dripping, do not waste material, also can ensure the bottle clean and tidy.

The size of the filling head can be customized according to the caliber of the bottle, ensuring that this machine is absolutely suitable for your product

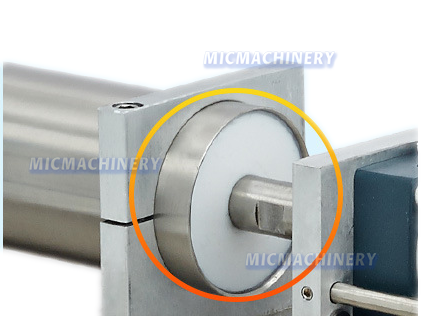

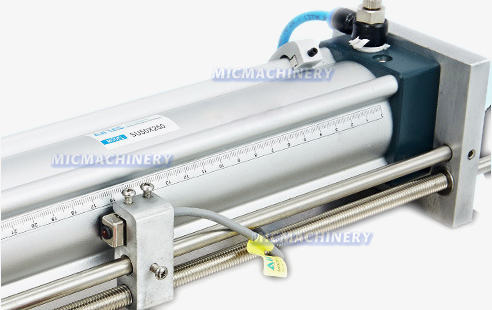

Air Cylinder

The cylinder is through the internal pumping system, the material out from the material cylinder, and then in the filling. Driven by electricity and air compressor.The machine is all made of SUS304. Corrosion-resistant, compact structure, easy to operate, beautiful appearance, in line with GMP standards.

1. Filling with piston pump. Driven by electricity and air compressor.

2. Filling volume can be easily adjusted.

3. The machine is all made of SUS304. Corrosion-resistant, compact structure, easy to operate, beautiful appearance, in line with GMP standards.

4. It can work automatically or controlled by a operation pedal.

5. Has single head, double heads and full pneumatic model. Our machine support special customization.

6. It is suitable for filling liquid and paste materials such as water, juice, oil, sauce, toothpaste, cosmetic cream, hand cream, honey, peanut butter etc. lt is widely used in chemical industry, food, cosmetic, medicine, etc.

if you want to know more models of filling machine, you can refer to the table below

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

in short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Model |

MIC V01 |

|

Voltage |

220V/380V 50/60HZ |

|

Power |

30W |

|

Air Pressure |

0.4-0.6MPa |

|

Filling Speed |

5-25 bottles/min |

|

Filling Accuracy |

±1% |

|

Dimension(L*W*H) |

1000*480*700mm |

|

Filling Range |

10-20ML. 25-250ML. 50-500ML.100-1000ML.250-2500ML. 1000-5000ML |

|

Weight |

35 Kg |

|

Filling Material |

Juice, Oil, Water, Sauce, Toothpaste, Cosmetic Cream, Hand Cream, Honey and etc |

|

Note: If you need special customization. please feel free contact me. |

|