Syrup Filling Machines: Innovations and Trends in 2025

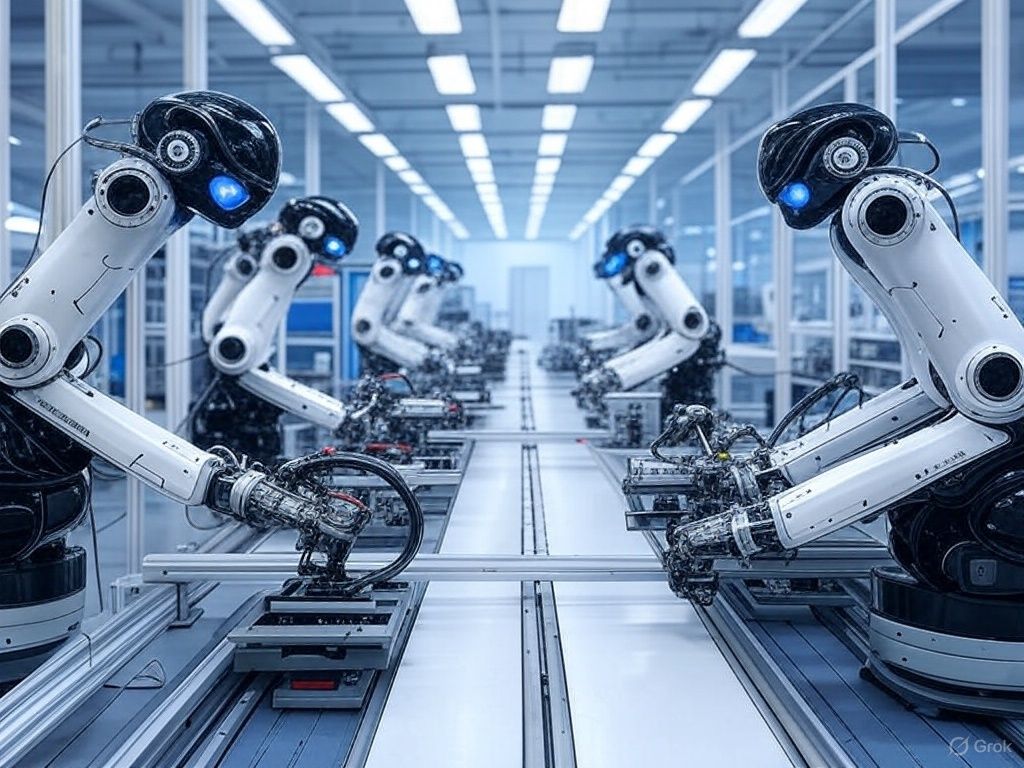

Automation Drives Efficiency and Precision

☑ Precision: Automated systems guarantee uniform fill levels, critical for syrup products that often require strict dosing.

☑ Speed: High-speed filling can reach hundreds or even thousands of bottles per hour, meeting mass production demands.

☑ Reduced Human Error: Automated processes minimize manual intervention, reducing contamination risks and inconsistent filling.

Modern automatic filling machines also come equipped with self-cleaning features and modular designs, allowing easier maintenance and quicker format changes, important for companies running multiple syrup varieties or bottle sizes.

Adaptability to Diverse Syrup Types and Packaging

Syrups vary greatly in viscosity and ingredient composition—from thin, watery syrups to thick, highly viscous formulations like molasses or medicinal syrups. The versatility of the liquid syrup filling machine in handling such diversity is crucial for producers who wish to expand their product lines without investing in separate filling equipment.

Advanced machines use precision pumps such as peristaltic or piston pumps that adapt filling pressure and speed to different syrup types, preventing foam formation or overflow. Additionally, nozzles are designed to minimize dripping and splashing, maintaining clean production environments.

● Glass bottles

● Plastic bottles (PET, HDPE)

This flexibility is particularly valuable for contract packagers and co-manufacturers who handle multiple client requirements, reducing downtime and setup costs.

Integration with Smart Factory Technologies

The concept of the “smart factory” is increasingly realized in syrup filling operations. Integration of automatic syrup filling machines with Internet of Things (IoT) platforms enables real-time monitoring of machine performance and product quality.

Key advantages include:

● Predictive Maintenance: IoT sensors detect wear or irregularities early, preventing unexpected breakdowns and costly downtime.

● Data Analytics: Production data on fill accuracy, cycle times, and reject rates can be analyzed to optimize processes continuously.

● Remote Monitoring: Supervisors can oversee multiple filling lines across facilities from a centralized dashboard, improving responsiveness.

Such digital integration aligns with Industry 4.0 principles and empowers manufacturers to achieve higher productivity, traceability, and compliance.

Watch the Syrup Filling Machine in Action

Sustainability and Environmental Considerations

Sustainability is no longer optional but a core focus in the packaging industry, including syrup filling. Manufacturers are adopting machines that reduce product waste and minimize energy consumption. Features such as accurate dosing eliminate overfills, cutting raw material waste.

Moreover, many syrup filling machines are designed to be compatible with eco-friendly packaging materials, such as biodegradable bottles or recyclable plastics, supporting circular economy goals. Energy-efficient motors and pneumatic systems also reduce the carbon footprint of filling operations.

Our company prioritizes these sustainability initiatives to help clients meet environmental regulations and consumer expectations for greener products.

Customized Solutions for Specialty Syrups

Manufacturers can now order tailored liquid syrup filling machines equipped with features like:

● Temperature control to preserve ingredient integrity

● Low-shear pumps to prevent damage to delicate components

● Multi-head filling for small batch sizes or varied fill volumes

This customization supports the trend toward personalized nutrition and premium products, enabling businesses to differentiate in crowded markets.

Mic Machinery has been at the forefront of providing such bespoke solutions, ensuring our clients can meet these growing demands with cutting-edge technology.

Future Outlook: Embracing Innovation in Syrup Filling

Moreover, modular filling systems will become more popular, letting manufacturers scale capacity easily and adapt to new packaging trends. The combination of sustainability, digitalization, and customization will drive the industry to meet consumer expectations and regulatory demands.

In summary, syrup filling machines are no longer simple dispensers—they are intelligent, adaptable components of sophisticated production ecosystems that power today’s and tomorrow’s beverage and liquid product markets. Our company remains committed to delivering these advanced solutions to support manufacturers worldwide.

Mic Machinery Technical Specifications of the Syrup Filling Machine

|

Model |

|||||||||

|

Capacity |

30-50 Bottles/min |

30-80 vials/min |

30-450 Bottles/min |

10,000 bottles/hour |

60-80 bottles/min |

200 Bottles/min |

30-50BPM |

12000bph |

20-40 Bottles/min |

|

Power |

30.0KW |

2.0KW |

2.5KW |

2.5KW |

1.5Kw |

3.0KW |

2.0 kw |

0.37KW |

2.0Kw |

|

Dimensions (mm) |

10500×1500×2000 |

2000x1000x2400 |

6000x1000x1700 |

3200×1200×1850 |

2800×1200×1850 |

3300×1200×1750 |

2000×1000×1500 |

600×800×2800 |

2100×1200×1500 |

|

Filling Speed |

30-50 Bottles/min |

30-80 vials/min |

30-450 Bottles/min |

10,000 bottles/hour |

60-80 bottles/min |

200 Bottles/min |

30-50BPM |

12000bph |

20-40 Bottles/min |

|

Filling Heads |

- |

4 |

4, 12, 16 |

12 |

6 |

- |

- |

- |

4 |

|

Weight (kg) |

- |

650kg |

- |

- |

- |

1500Kg |

600 kg |

200KG |

650 kg |

|

Other Specifications |

Sterile Syrup Filling |

Peristaltic pump, 4 nozzles |

Cap screwing rate ≥99% |

8 capping heads, cap sealing qualification rate ≥99.9% |

Sealing rate ≥99.5% |

Filling pass rate 99.9%, upper cover rate 99.9% |

Rotation (rolling) Cover pass rate ≥99% |

Compressed air consumption 1m³/min (0.6MPa) |

4 Filling Heads, bottle type: glass or plastic, cap type: plastic or aluminum |