- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Mic Machinery is proud to introduce the Automatic Single Head Horizontal Silicone Filling Machine, designed to streamline production processes for manufacturers in various industries. This machine offers efficient and precise filling capabilities for a variety of silicone-based products, including sealants, adhesives, and lubricants. With years of expertise in automation technology, we provide solutions that maximize productivity while maintaining the highest standards of quality.

Key Features and Advantages

Our Silicone Filling Machine is engineered for optimal performance, offering several key features:

√ High Precision: The machine ensures consistent and accurate filling of silicone materials, reducing waste and improving product consistency.

√ User-Friendly Interface: Equipped with an intuitive control panel, operators can easily adjust the filling volume, speed, and timing to suit different production needs.√ Horizontal Design: The horizontal structure allows for easy integration into existing production lines, saving space and improving workflow efficiency.

√ Versatility: Capable of handling various viscosities, the machine adapts to different types of silicone materials, such as adhesives, sealants, and lubricants.

√ Automatic Operation: This machine automates the entire filling process, reducing manual labor and increasing production speed.

These features combine to enhance efficiency, minimize errors, and ensure high-quality output for a wide range of applications.

Reliable Silicone Tube Filling Machine

The Silicone Tube Filling Machine is designed to fill silicone materials into tubes with precision and ease. Ideal for manufacturing silicone-based products like sealants, adhesives, and lubricants, it ensures uniform filling across all tubes, enhancing product reliability. The machine is equipped with advanced technology that ensures tight seals and prevents leakage, making it ideal for products that require airtight packaging. Its automated process significantly reduces human error and increases production speed.

Efficiency and Flexibility for Sealant Cartridge Production

Our machine is also perfectly suited for sealant cartridge filling machine applications. With the ability to handle various viscosities of silicone, it ensures that the correct amount of material is dispensed into each cartridge. The automatic nature of the machine reduces the need for manual intervention, allowing for consistent, high-quality output with minimal labor. It is ideal for industries that require bulk filling of sealant cartridges for use in construction, automotive, or DIY applications.

Customization and Versatility for Various Applications

Mic Machinery’s Automatic Single Head Horizontal Silicone Filling Machine is designed with customization in mind. Depending on the specific needs of your production line, we offer several options:

● Adjustable filling speeds for different production capacities;

● Customizable nozzles for varying tube and cartridge sizes;● Ability to handle different silicone formulations, including high-viscosity materials.

These customizable features allow manufacturers to fine-tune their operations for greater flexibility and higher production efficiency. Our machine can seamlessly adapt to the unique needs of your business, ensuring optimal performance in any setting.

Quality and Precision from Mic Machinery

At Mic Machinery, we prioritize both innovation and quality. Our Silicone Filling Machine is built with high-grade materials, ensuring long-lasting durability and reliable performance. With an emphasis on precision, this machine guarantees that every unit is filled accurately, enhancing product consistency and reducing material waste. The robust design ensures that the Silicone Tube Filling Machine and sealant cartridge filling machine operate efficiently for years, making it a smart investment for any manufacturing line.

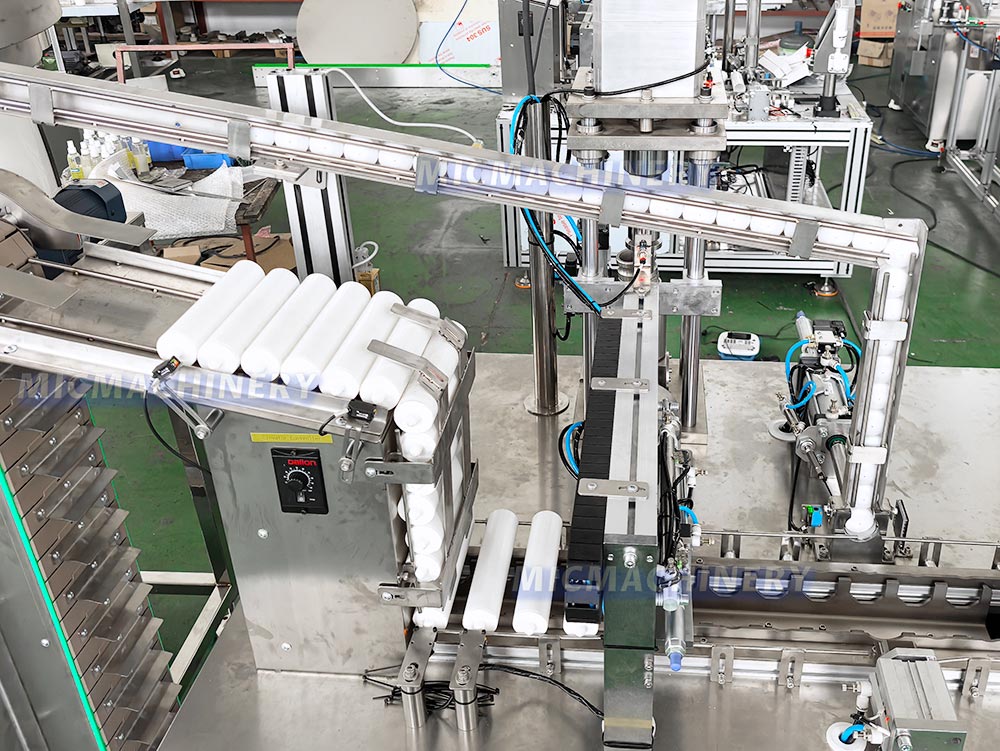

Conveyer Belt

The conveyer belt in the Silicone Filling Machine ensures smooth and continuous movement of tubes or cartridges during the filling process. Designed for stability and precision, it synchronizes perfectly with the filler, improving efficiency, reducing handling time, and minimizing production errors.

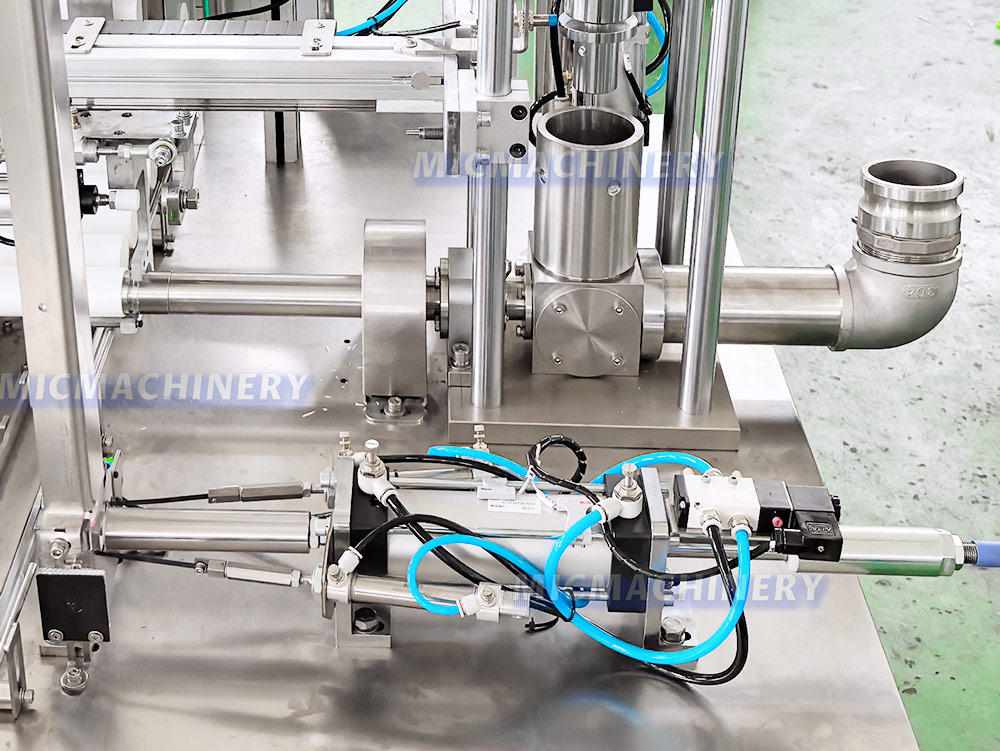

Filling head

The filling head in a silicone filling machine is a critical component designed to accurately dispense silicone sealants or other viscous fluids. It ensures precise, controlled filling with minimal waste, contributing to improved efficiency and product consistency in manufacturing processes.

Control Panel

The control panel of the Silicone Filling Machine features a user-friendly touchscreen interface, allowing operators to easily adjust filling volume, speed, and timing. With real-time monitoring and intuitive settings, it enhances efficiency, accuracy, and process stability during operation.

|

Power Supply

|

380V/50H

|

|

Air Supply

|

0.5MPa

|

|

Air Consume

|

<0.3m 3 /min

|

|

Filling Volume

|

MAX 310m

|

|

Volume Precision

|

≤±0.5℅ |

|

Productivity

|

20~35pcs/min

|

|

Tube Diameters

|

50mm*300ML

|

|

Dimension L*W*H

|

4200*1450*2200

|

|

Weight

|

850KG

|

- MIC Single Head Horizontal Silicone Filling Machine

- MIC Semi Automatic Silicone Tube Filling Machine

- MIC Silicone Pre-Made Pouch Filling Machine

- MIC Semi Automatic Horizontal Cartridge Silicone Filling Machine ( 10-20 Bottles/Min )

- MIC SF1 Semi Automatic Vertical Silicone Cartridge Filling Machine

- MIC LL30 Semi Automatic Horizontal Silicone Filling Machine

- MIC Automatic Vertical Cartridge Silicone Filling Machine

- MIC Semi Automatic Vertical Silicone Tube Filling Machine

- MIC Automatic Single Head Horizontal Silicone Filling Machine

- MIC Dual Cartridge Silicone Filling Machine ( 15-23 Cartridges/Min)

- MIC Dual Cartridge Silicone Sealant Filling Machine (15-23 Cartridges/Min)

- MIC-L45I Silicone Tube Filling Machine ( 40-45 Tubes/min )

- MIC-L60 Automatic Silicone Tube Filling Machine ( 30-75 Tubes/min )

- MIC Automatic Silicone Filling Machine ( 40-60 Cartridges/min )

- MIC Silicone Sealant Filling Machine ( 10-25 Pieces/min )

- MIC Silicone Filling Machine ( 10-30 Bottles/min )

- MIC Silicone Cartridge Filling Machine ( 10-30 Bottles/min )

- MIC Semi Automatic Silicone Cartridge Filling Machine ( 20-30 Cartridges/min )