- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

The MIC LL30 Semi Automatic Horizontal Silicone Filling Machine is designed to meet the growing demand for precision, efficiency, and consistency in silicone packaging. Built with advanced engineering, it ensures smooth production performance while maintaining high-quality standards.

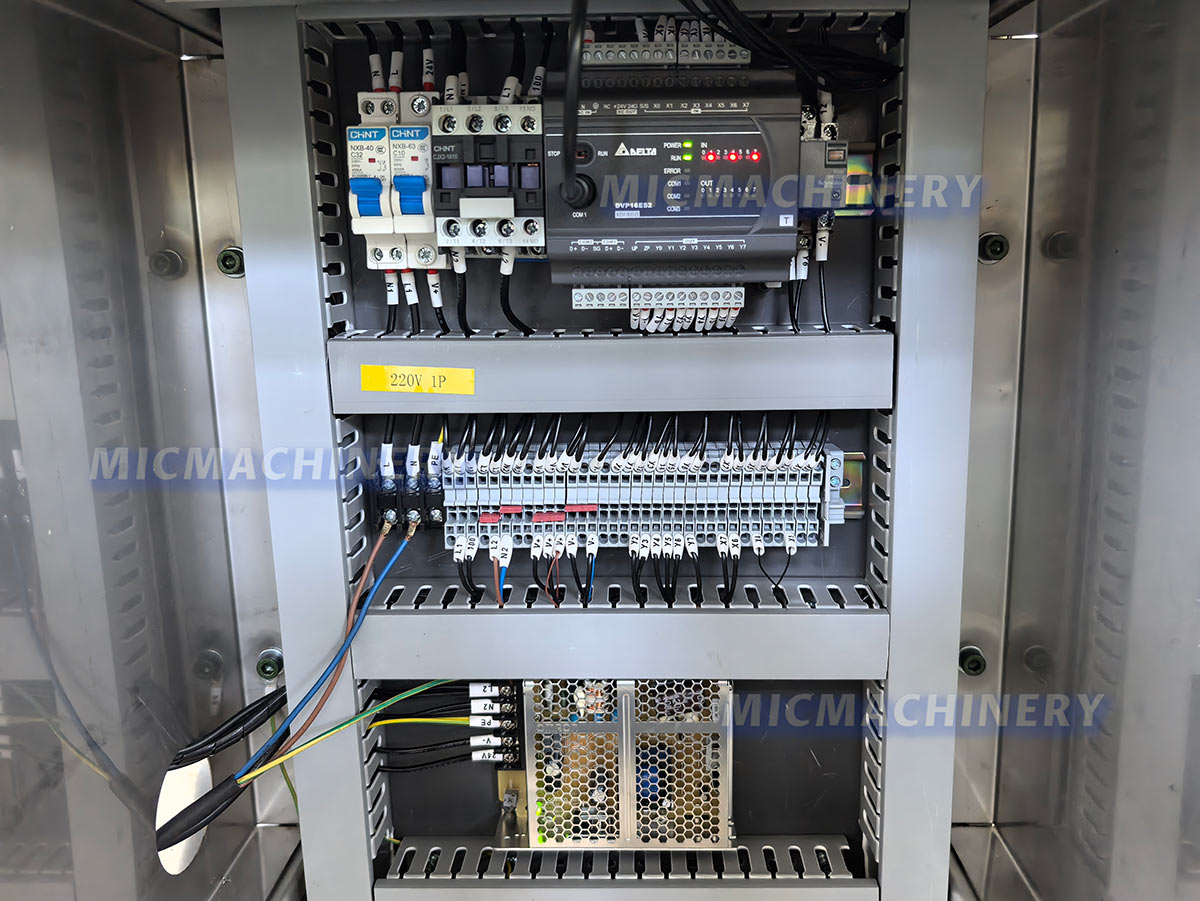

Circuit Board

The circuit board in a Silicone Filling Machine ensures precise control and stable operation by managing filling volume, speed, and automation functions. Designed for durability, it optimizes performance, minimizes errors, and guarantees consistent results in silicone cartridge production.

Touch Screen Display

The touch screen display in a Silicone Filling Machine provides an intuitive interface for operators, allowing easy adjustment of filling parameters, real-time monitoring, and quick troubleshooting. Its user-friendly design enhances efficiency, accuracy, and reliability in silicone cartridge production.

Tube Discharge Guide

The tube discharge guide in a Silicone Filling Machine directs filled cartridges smoothly from the machine to the collection area. Designed for precision and stability, it prevents spillage, reduces handling errors, and ensures efficient transfer, supporting seamless silicone cartridge production.

Mic Machinery is committed to providing reliable equipment for industries working with adhesives, sealants, and construction materials. The LL30 model offers professional-grade performance, making it suitable for manufacturers looking to enhance productivity. Whether referred to as a Silicone Filling Machine, Silicone Sealant Filling Machine, or Silicone Cartridge Filling Machine, this equipment integrates versatility with durability, covering a wide range of packaging requirements.

Key Features of the MIC LL30

The MIC LL30 has been engineered with thoughtful details to ensure safe and efficient operation. Some of its main features include:

● Horizontal structure for stable and continuous filling of silicone products.

● Adjustable filling volume to meet different cartridge and container sizes.● User-friendly control panel that simplifies setup and operation.

● Stainless steel contact parts to ensure product purity and easy cleaning.

● Compact design for integration into small to medium-sized production lines.

With these features, the LL30 stands out as a dependable solution for businesses requiring a professional Silicone Filling Machine.

Advantages for Manufacturers

Choosing the MIC LL30 provides significant benefits for both large and small-scale producers. These include:

1.Precision Filling – Ensures uniformity in every cartridge, which is crucial for silicone sealant applications.

2.Operational Efficiency – Reduces manual labor while speeding up filling tasks.

3.Cost-Effectiveness – Offers reliable performance at a reasonable investment.

4.Flexible Applications – Adaptable to various formulations of silicone and sealants.

5.Consistent Output – Minimizes product waste and ensures long-term reliability.

These advantages make the machine an ideal Silicone Sealant Filling Machine for industrial and commercial use.

Applications Across Industries

The MIC LL30 is widely used in sectors where silicone products are indispensable. Industries that benefit from this model include:

● Construction materials: For sealing, bonding, and insulation applications.

● Automotive sector: For adhesives and specialty silicone uses.

● Household products: For producing sealant cartridges used in DIY and repair.

● Industrial adhesives: For specialized manufacturing environments.

This versatility ensures that the MIC LL30 is recognized as a highly adaptable Silicone Cartridge Filling Machine.

MIC Machinery’s Commitment to Quality

As a trusted manufacturer, Mic Machinery continues to uphold its reputation for precision engineering and customer-focused solutions. The MIC LL30 is not just a machine—it represents the company’s dedication to combining innovation with practicality. Designed to serve global clients, it meets strict international standards and supports long-term productivity. For businesses seeking a dependable Silicone Filling Machine, the LL30 reflects both technical expertise and a professional spirit that ensures success in silicone packaging operations.

|

Weight |

500KG |

Dimension |

1100* 800*1 600mm |

|

Application |

100-400ml cartridge |

Power |

1. 5Kw |

|

Air pressure |

0.6 Mpa compressed air |

Production Speed |

0-20 pcs per min |

|

Filling material |

PU glue, silicone sealant |

Filling method |

Piston filling connect drum press |

- MIC Single Head Horizontal Silicone Filling Machine

- MIC Semi Automatic Silicone Tube Filling Machine

- MIC Silicone Pre-Made Pouch Filling Machine

- MIC Semi Automatic Horizontal Cartridge Silicone Filling Machine ( 10-20 Bottles/Min )

- MIC SF1 Semi Automatic Vertical Silicone Cartridge Filling Machine

- MIC LL30 Semi Automatic Horizontal Silicone Filling Machine

- MIC Automatic Vertical Cartridge Silicone Filling Machine

- MIC Semi Automatic Vertical Silicone Tube Filling Machine

- MIC Automatic Single Head Horizontal Silicone Filling Machine

- MIC Dual Cartridge Silicone Filling Machine ( 15-23 Cartridges/Min)

- MIC Dual Cartridge Silicone Sealant Filling Machine (15-23 Cartridges/Min)

- MIC-L45I Silicone Tube Filling Machine ( 40-45 Tubes/min )

- MIC-L60 Automatic Silicone Tube Filling Machine ( 30-75 Tubes/min )

- MIC Automatic Silicone Filling Machine ( 40-60 Cartridges/min )

- MIC Silicone Sealant Filling Machine ( 10-25 Pieces/min )

- MIC Silicone Filling Machine ( 10-30 Bottles/min )

- MIC Silicone Cartridge Filling Machine ( 10-30 Bottles/min )

- MIC Semi Automatic Silicone Cartridge Filling Machine ( 20-30 Cartridges/min )