- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

1.This machine adopt PLC control system combine with weight system to control all machine.

2.Use fixed flow pipeline to set parameter.

3. Adopt large flow quality to control to reach approaching numerical( the set flow quality,such as set 20L, it will flow large quality to approaching 20L)

4.Then through small flow quality to supplement remain quality, in order to reach set quality filling, promise the filling quality is accuracy, and do not waste the material.

5.Filling volume range can adjust between 5L-25L.

6.This machine meeting GMP standard.

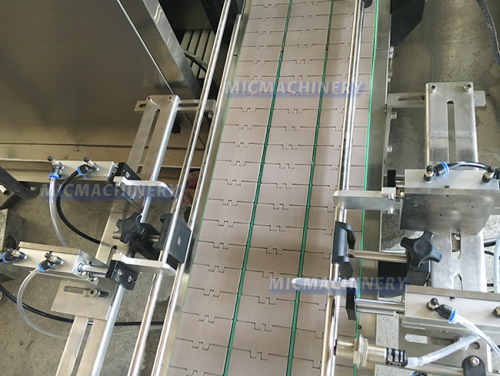

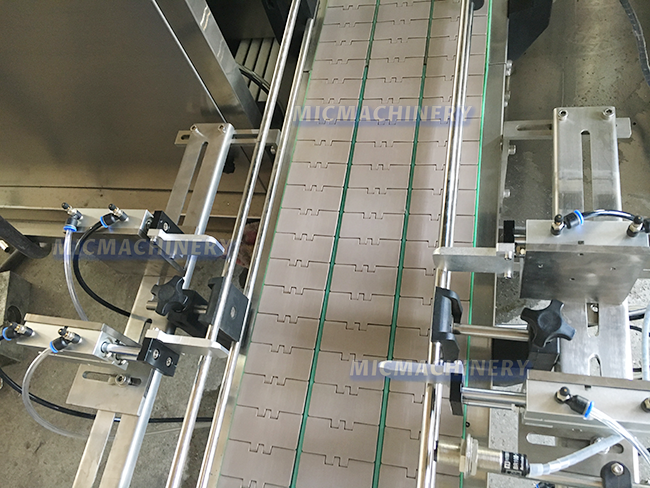

Conveyor belt

When the barrel is placed on it, the conveyor belt takes the barrel into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of barrel,The width between the two pipes can be adjusted according to your container,ensure smooth barrel safely from the conveyor belt moved .

on the side of the conveyor is equipped with sensors that can automatically identify when the barrel to go out or, in order to send signals to filling station of screw cap.

A roller with a weighing device

This device is specially designed for the filling of large volume barrel products, with a weighing system below, during the filling process, the barrel is placed on the top, when the weight of the barrel reaches the specified amount, the machine automatically stops filling. To achieve precise filling, efficient work.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

pesticides,chemical,cosmetic and other corrosive,High Viscosity Materials, Liquid soap , oil product ,Lotion And So On |

|||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

|||||

|

Speed (basis on 50-500ml) |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

|||||

|

Power |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

Filling head

4 heads

Filling volume range

5L-25L

Production speed

192-220 b/h (25L for example)

Voltage

380V three-phase four-wire

Power

3.0Kw

Long barrels

180mm-300mm

Wide application barrels

120mm-250mm

Apply high barrel

280mm-450mm

Filling error

≤±3‰

Air consumption

0.6m3/min

Work pressure

0.55Mpa-0.65Mpa

Size

2500mm × 1600mm× 2500mm

Weight

700 kg

|

Touch screen |

Canada xinjie color |

|

PLC |

Schneider |

|

Solenoid valve |

Taiwan Airtac |

|

Optoelectronic system |

OPTEX |

|

Micro differential pressure switch |

Netherlands |

|

Servo motor |

Taiwan TECO |

|

Air source treatment |

Taiwan Airtac |

|

Button and low voltage electric appliance |

Schneider |

|

Ball screw |

Taiwan |

|

Reducer |

Taiwan VGM |

|

Switching power supply |

Taiwan meanwell |

|

Material |

Contact with the material parts of the 316 materials, and the rest of the 304 stainless steel |

- 502 glue filling capping machine ( MIC-M30 Bottle Glue Filling & Capping Machine)

- Chemical liquid filling machine (Such as pesticides, disinfectants, medical alcohol, etc.)

- Preservative anti-corrosive liquid filling machine (MIC-ZF12 Bleach anti-corrosive filling machine)

- Butter grease filling machine (MIC-ZF4 weighing filling machine)

- Detergent liquid filling machine(MIC-ZF20 20 heads piston filling and capping machine)

- Car lubricate oil filling machine (MIC-ZF8 piston oil filling capping machine)

- L45I super AB 502 glue filling sealing machine (MIC-L45I aluminum tube filling sealing machine)

- Glue silicone sealant tube dual cartridge filling machine

- Semi Automatic Silicone Filling Machine ( Speed 20-30 Cartridges per minute )