- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

This machine is suitable for filling in water and cream products, especially for high viscosity material (such as liquid soap , detergent , dishwashing liquid , oil , sauce etc.) the effect is obvious.

PLC programming control, with a touch screen and man-machine interface system;

automatic bottle feeding, automatic filling, automatic bottle;

the servo motor drive, double screw drive, the control piston rod movement to ensure the filling stability, filling accuracy higher.

It can be with the capping machine, labeling machine supporting the formation of water production line. It integrates light, machine, electricity and gas into one body. Is an easy to operate filling machine. With stable and reliable operation, high production efficiency, strong adaptability.

filling head

The detergent is put into the material cylinder, and the piston to pump the detergent into the measuring cylinder. Then the piston moves up to send the detergent to the filling pipe. At the same time, when the bottle enters the filling machine through the conveyor belt, the filling head moves down to start filling. After filling, the conveyor belt will automatically send the bottle to the capping station.

(Filling process without drip leakage, the number of filling head can be customized according to your needs and diameter of filling head basis on the diameter of your barrel’s mouth)

the three-way valve and Measuring cylinder

the three-way valve is controlled by PLC system, The three-way valve rotates internally to adjust the connection between the material box and the measuring cylinder cylinder or the measuring cylinder cylinder and the filling pipe. Accordingly it controls the movement of materials from the material tank to the dosing cylinder and then to the filling pipe.

Measuring the effect of cylinder is primarily a quantitative filling, it allows you to have higher filling accuracy,

Main working process: downward movement of the piston to fill the material from the material cylinder to the measuring cylinder, and then controls the upward movement of the piston to send the material to the filling pipe and start filling.

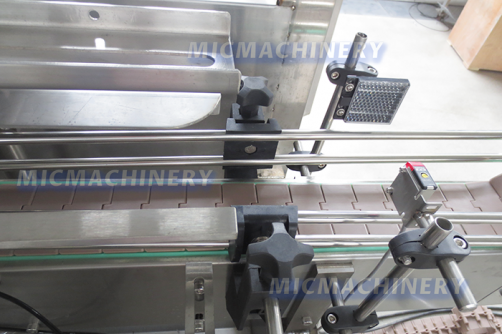

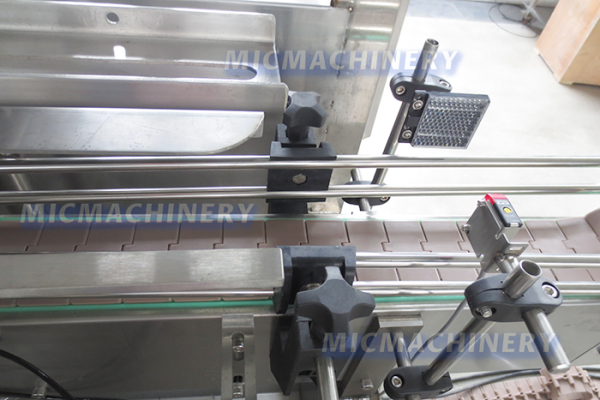

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of bottle,The width between the two pipes can be adjusted according to your container,ensure smooth bottle safely from the conveyor belt moved .

on the side of the conveyor is equipped with sensors that can automatically identify when the bottle to go out or, in order to send signals to filling station of screw cap.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

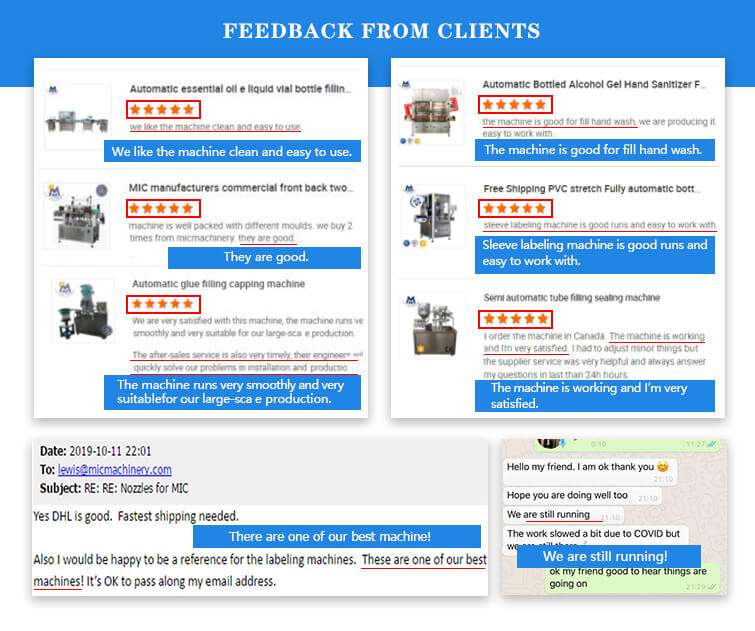

in short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Filling head |

20 heads |

|

Filling volume range |

200ml-2500ml |

|

Production speed |

≤4000 Bph basis on1L bottle |

|

Voltage |

220V/380V |

|

Power |

3.0Kw |

|

Suitable bottle’s diameter |

Ф40mm-Ф100mm |

|

Filling error |

≤±3‰ |

|

Work pressure |

0.55Mpa-0.65Mpa |

|

Size |

2800mm × 1400mm× 2500mm |

|

Weight |

1000 kg |

|

Touch screen |

Canada xinjie color |

|

PLC |

Schneider |

|

Solenoid valve |

Taiwan Airtac |

|

Optoelectronic system |

OPTEX |

|

Micro differential pressure switch |

Netherlands |

|

Servo motor |

Taiwan TECO |

|

Air source treatment |

Taiwan Airtac |

|

Button and low voltage electric appliance |

Schneider |

|

Ball screw |

Taiwan |

|

Reducer |

Taiwan VGM |

|

Switching power supply |

Taiwan meanwell |

|

Material |

Contact with the material parts of the 316 materials, and the rest of the 304 stainless steel |

- 502 glue filling capping machine ( MIC-M30 Bottle Glue Filling & Capping Machine)

- Chemical liquid filling machine (Such as pesticides, disinfectants, medical alcohol, etc.)

- Preservative anti-corrosive liquid filling machine (MIC-ZF12 Bleach anti-corrosive filling machine)

- Butter grease filling machine (MIC-ZF4 weighing filling machine)

- Detergent liquid filling machine(MIC-ZF20 20 heads piston filling and capping machine)

- Car lubricate oil filling machine (MIC-ZF8 piston oil filling capping machine)

- L45I super AB 502 glue filling sealing machine (MIC-L45I aluminum tube filling sealing machine)

- Glue silicone sealant tube dual cartridge filling machine

- Semi Automatic Silicone Filling Machine ( Speed 20-30 Cartridges per minute )