- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

This filling machine is suitable for:

pesticides, chemicals, bottled agent type liquid dispensing, bottle filling, Applicable to a variety of different types of containers.

This machine function is:

1. This machine combines optical, mechanical, electrical, gas in one machine.

2. Adopt through control filling time to reach different volume filling.

3. Filling time can be precisely controlled to a hundredth of a second.

4. The filling process is completed under the PLC program control on the touch screen.

5. Having a stable and reliable operation, high efficiency, adaptability, the filling volume of measurement specification can be changed within a few minutes.

6. Filling valve use imported brands, advanced technology, sophisticated, non-drip filling phenomenon.

7. All parts frame, conveyor ,valve ,filling nozzle use anti-corrosion material.

8. Can customize vacuum or diving filling avoid have foma when filling.

This machine is our MIC automatic inline straight line normal pressure filling machine, can Prevent corrosion.

It can be used with capping machine, labeling machine supporting the formation of the production line.

This machine is guaranteed for one year and you can extent your guarantee easily by discuss with our sales.

Which you might be interested, under guaranteed, machine parts got broken by daily use, we will replace it once we are informed by free DHL.

filling head

This machine is specially designed for filling corrosive liquids. All parts in contact with the liquid are made of antiseptic materials.

Main work process: When the bottle is under the filling head, the internal system controls the anti-corrosion filling head to move down, precise filling, no bottle no filling, special design can achieve no bubble filling.

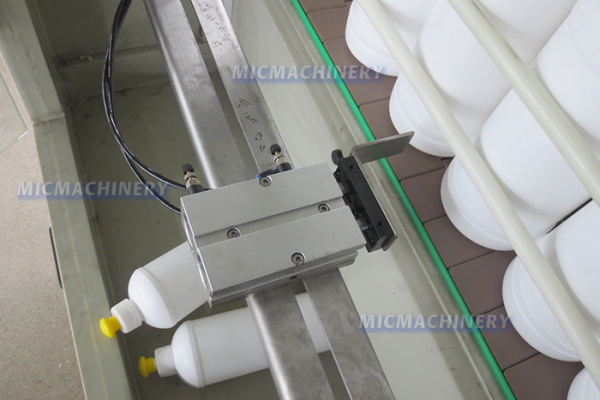

Bottle block air cylinder

When the bottle can reach a certain number, there is a special infrared sensor on the bottle track to receive the induction, and then automatically stuck behind the bottle, in front of the bottle after the bottle filling, and then let the behind the bottle to fill the vacancy, so as to achieve no bottle no filling

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of bottle,The width between the two pipes can be adjusted according to your container,ensure smooth bottle safely from the conveyor belt moved .

on the side of the conveyor is equipped with sensors that can automatically identify when the bottle to go out or, in order to send signals to filling station of screw cap

in short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Filling Heads |

12 heads |

|

Min Filling Volume |

500ml-5000ml |

|

Production Speed |

2000 Bph(basis on 5L bottle) 3000-5000Bph (basis on 1L) |

|

Voltage |

220V/380V |

|

Power |

1 kw |

|

Application Bottle Type |

1-5L different shape bottles |

|

Filling Error |

≤±0.5% |

|

Work Pressure |

0.55Mpa-0.65Mpa |

|

Size |

2000mm × 1000mm× 2200mm |

|

Weight |

700 kg |

|

Name |

Brand |

|

Touch Screen |

Canada Xinjie |

|

PLC |

Schneider France |

|

Frequency Conversion |

Schneider France |

|

Pneumatic Valve |

UAA USA |

|

The Electromagnetic Valve |

AirTac Taiwan |

|

Air Cylinder |

AirTac Taiwan |

|

Air Source |

AirTac Taiwan |

|

Photovoltaic Systems |

OPTEX Japan |

|

Differential Pressure Switch |

Johnson USA |

|

Switching Power Supply |

Mean Well Taiwan |

|

Machine Frame Material |

Use PVC Polypropylene material make, the material of our machine’s tank is Acid and alkali corrosion resistant material can resistant Acid and alkali and corrosion. |

- 502 glue filling capping machine ( MIC-M30 Bottle Glue Filling & Capping Machine)

- Chemical liquid filling machine (Such as pesticides, disinfectants, medical alcohol, etc.)

- Preservative anti-corrosive liquid filling machine (MIC-ZF12 Bleach anti-corrosive filling machine)

- Butter grease filling machine (MIC-ZF4 weighing filling machine)

- Detergent liquid filling machine(MIC-ZF20 20 heads piston filling and capping machine)

- Car lubricate oil filling machine (MIC-ZF8 piston oil filling capping machine)

- L45I super AB 502 glue filling sealing machine (MIC-L45I aluminum tube filling sealing machine)

- Glue silicone sealant tube dual cartridge filling machine

- Semi Automatic Silicone Filling Machine ( Speed 20-30 Cartridges per minute )