- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

https://www.micmachinery.com/edible-oil-filling-machine

Embark on a seamless journey of precision and sophistication in edible oil packaging with the Glass Bottle Oil Filling Machine, a cutting-edge solution meticulously designed to redefine the standards of liquid filling in the food industry. This specialized equipment takes center stage in ensuring the accurate and automated filling of edible oils into glass bottles, catering to the unique needs of manufacturers. As we explore its distinctive product characteristics, versatile applications, and the intricate mechanical principles guiding its operation, we uncover the essence of excellence in glass bottle oil filling. From classic olive oils to gourmet blends, this machine guarantees each glass bottle is filled with precision, speed, and the promise of maintaining the purity of this culinary essential.

Product Characteristics:

The Glass Bottle Oil Filling Machine stands out with exceptional characteristics meticulously engineered for efficiency and accuracy. Crafted from high-quality materials, often stainless steel, it ensures durability while adhering to the highest standards of hygiene for food-grade applications. Featuring automated bottle feeding, precise filling, and capping mechanisms, the machine epitomizes a harmonious blend of speed and accuracy in glass bottle oil production. User-friendly interfaces equipped with programmable controls accommodate various glass bottle sizes and edible oil viscosities, ensuring each product receives a consistent and precise fill. Anti-drip features and customizable settings preserve the quality of edible oil formulations, delivering products that resonate with both efficiency and the promise of superior taste.

Product Applications:

The applications of the Glass Bottle Oil Filling Machine span the entire spectrum of edible oil manufacturing, providing a comprehensive solution for efficient and automated filling of glass bottles. Whether producing standard vegetable oils, premium olive oils, or artisanal blends, this machine ensures uniformity in dosage and presentation. Its adaptability caters to the dynamic requirements of the food industry, where each glass bottle of edible oil requires a tailored approach to dispensing, capping, and preserving its unique flavor profile.

Mechanical Principle:

At its core, the Glass Bottle Oil Filling Machine operates on advanced mechanical principles designed for precision, speed, and automation. Utilizing volumetric or gravimetric filling systems, filling nozzles, and capping mechanisms, the machine accurately measures and dispenses the specified quantity of edible oil into individual glass bottles. Automated capping ensures a secure seal, preserving the freshness and flavor of the oil. Integrated sensors and programmable logic controllers (PLCs) oversee the entire process, ensuring uniformity, minimizing errors, and enhancing the overall efficiency of glass bottle oil filling operations.

In conclusion, the Glass Bottle Oil Filling Machine symbolizes manufacturing excellence in the food industry. Its exceptional product characteristics, diverse applications, and advanced mechanical principles make it an indispensable asset for edible oil producers globally. Embracing cutting-edge technology, this machine not only ensures the precision and speed of glass bottle oil filling but also upholds the highest standards of presentation, consistency, and flavor preservation. As a fundamental component in various production workflows, it continues to shape the way glass-bottled edible oil products are filled, ensuring each bottle embodies the essence of automation and the promise of superior taste.

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of bottle,The width between the two pipes can be adjusted according to your container,ensure smooth bottle safely from the conveyor belt moved .

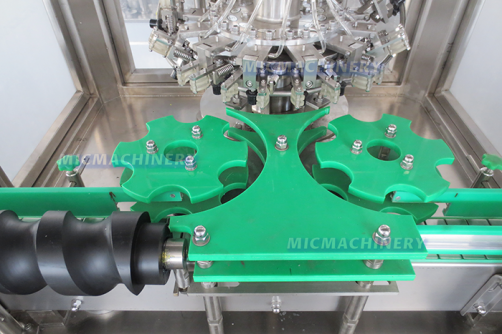

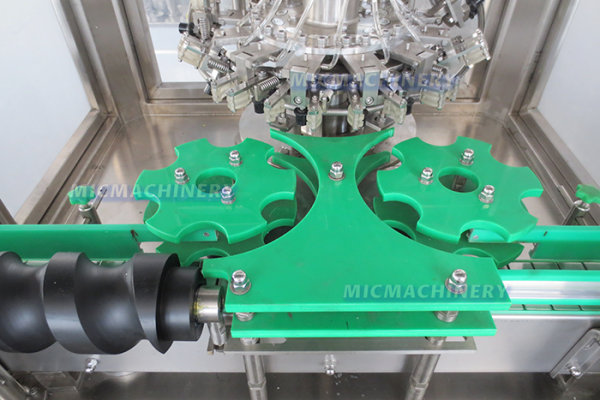

Glass bottle washing machine

The function of the bottle washing machine is to clean the bottle to be filled, to ensure that the inside of the bottle is clean, the machine adopts the rotating bottle washing machine, can better clean the bottom of the bottle and the bottle wall. There are two round chucks on the bottom,This effectively saves space.

Main working process: the bottle enters the first chuck through the conveyor belt,screw and dial wheel, then the bottle washer washes the bottle carefully in all directions, and finally the cleaned bottle is sent to the conveyor belt.

Features:

1.Volumetric type quantitative filling can ensure high precision filling, do not waste materials. To make the filling process is stable and high efficient.2.The structural design of each part fully considers the health requirements, the filling cylinder,filling valve and parts in contact with the material are made of stainless steel 304, with good corrosion resistance.

3.This machine is equipped with a set of adjustment device, so that customers can fill 500ml~2000ml bottles without changing the measuring cup, only adjust the measuring cup capacity. No bottle no filling function.

4.The position turning block of the filling valve turns the position and opens the valve under the action of another cylinder. Cylinder backblowing anti-drip device.

5.It is mainly used for oil bottle filling and capping. Its structure is advanced, stable, reliable, safe operation, convenient maintenance, the use of frequency conversion speed control, high production efficiency, is the ideal equipment for big and medium sized food and oil factory.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC 18-4 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF12 |

MIC-ZF20 |

|||

|

Application |

vegetable oil , cooking oil , olive oil, edible oil, sunflower oil, peanut oil etc liquid like oil products, Sauce, Ketchup, Syrup, Detergent, Honey, Shampoo, Lotion, Lubricant oil, etc. |

|||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle ,Plastic Bottle Etc |

|||||||

|

Speed (basis on 50-5000ml) |

1800-2200B/H |

2000-6000B/H |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML,0.5-2L.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

|||||||

|

Power |

1.5Kw |

3Kw |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

2570*2300*2650 mm |

2400*1400*2500 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

5000Kg |

2500kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

In addition to,we have oil filling machine,edible oil filling machine,olive oil filling machine,cooking oil filling machine,vegetable oil filling machine,olive oil bottling machine,sunflower oil filling machine,

If you are more than interested in the machine ,you can contact us at market@micmachinery.com

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Power |

3Kw |

|

Filling heads |

18piece |

|

Sealing heads |

6piece |

|

Filling volume range |

0.5-2L |

|

Production capacity |

3000-6000CPH based on 500ml |

|

Filling temperature |

Room temperature |

|

Bottle diameter range |

Ф60-120MM |

|

Bottle height |

180-380MM |

|

Air pressure |

0.6-0.8Mpa |

|

Air consumption |

0.8-1.0m³/min |

|

Dimension |

2400×1400×2500mmm |

|

Weight |

2500Kg |

|

Name |

Brand |

|

Touch screen |

Siemens (Germany) |

|

Buttons |

Schneider (France) |

|

AC Contactor |

Schneider (France) |

|

PLC |

Mitsubishi (Japan) / Siemens (Germany) |

|

Frequency changer |

Schneider (France) |

|

Breaker |

Schneider (France) |

|

Air cylinder |

AirTAC (China) / FESTO (Optional) |

|

Solenoid valve |

AirTAC (China) / FESTO (Optional) |

|

Relay |

Omron (Japan) / Schneider (France) |

|

photoelectric sensor |

Autonics (Korea) / Omron (Optional) |

|

Proximity switch |

Autonics / Omron (Optional) |

- MIC Edible Oil Piston Filling Machine

- MIC Food Oil Gravity Filling Machine

- MIC Edible Oil Gravity Filling Machine

- MIC-ZF4 Bean Oil Filling Machine ( Oil, Detergent, Paint, 190-220 Barrels/h )

- MIC Tracking Type Edible Oil Filling Machine ( Olive Oil, Cooking Oil, 3000-3600 Bottles/h )

- MIC-ZF6 Olive Oil Bottling Machine ( Oil, Butter, Honey, 1300-1500 Bottles/h )

- MIC-ZF8 Sunflower Oil Filling Machine ( Oil, Sauce, Cream, 1800 Bottles/h )

- MIC-ZF8 Cooking Oil Filling Machine ( Oil, Honey, Sauce, 1800 Bottles/h )

- MIC-ZF12 Oil Bottle Filling Machine ( Oil, Paste, Cream, 3000 Bottles/h )

- MIC-ZF16 Olive Oil Filling Machine ( Oil, Sauce, Syrup, 3200 Bottles/h )

- MIC-ZF20 Vegetable Oil Filling Machine ( Oil, Cream, Honey, 4000 Bottles/h )

- MIC 18-4 Oil Filling Machine ( Oil, Paste, Honey, 1800-2200 Bottles/h )

- MIC 18-6 Edible Oil Filling Machine ( Olive Oil, Cooking Oil, 3000-6000 Bottles/h )

- MIC Glass Bottle Oil Filling Machine ( Olive Oil, Edible Oil, 3000-6000 Bottles/h )

- MIC-V01 Semi Automatic Oil Filling Machine ( Peanut Butter, Oil, Honey, 5-25 Bottles/h )