- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

1. The filled capsules go into the hopper by the lifting device (optional) or manual operation.

2. The capsule was unloaded one by one through the capsule unloading section, and the capsule was put down horizontally into the capsule rotating section.

3. Under the action of the capsule rotating section, the capsule is rotating.

Then, the capsule pushing section will accurately push the rotating capsule to the inspection area of the vision inspection system (the machine vision system will reflect the rotating capsule to the inspection system in an all-round way through multiple optical mirrors), and the last group of tested capsules will be sent to the discharge synchronously.

Finally, defective capsules are sent to the NG collector through the rejection system in the discharge mechanism, while qualified capsules are collected or go to next processes.

In the pharmaceutical industry, maintaining product quality and compliance with regulatory standards is critical. Automated visual inspection pharma systems have become essential tools for ensuring the safety, accuracy, and integrity of pharmaceutical products. These systems use cutting-edge imaging technologies, such as high-resolution cameras, sensors, and artificial intelligence (AI), to perform real-time inspections of pharmaceutical products. Automated visual inspection pharma is capable of detecting a wide range of defects including cracks, chips, contamination, or mislabeling, ensuring that only products meeting stringent quality standards reach the market. By automating the inspection process, these systems reduce human error, increase efficiency, and help pharmaceutical manufacturers maintain compliance with strict industry regulations.

One of the key applications of automated visual inspection pharma technology is in the inspection of capsules. The capsule vision inspection system is specifically designed to inspect pharmaceutical capsules for defects. Whether it's ensuring that capsules are properly filled, verifying the integrity of the capsule shell, or identifying any foreign particles inside, capsule vision inspection plays a vital role in ensuring product safety. Using specialized cameras and lighting techniques, capsule vision inspection systems can accurately identify even the smallest imperfections, helping manufacturers avoid costly recalls and maintain high-quality standards.

In a broader context, machine visual inspection is integral to many industries, especially in pharmaceutical manufacturing. Machine visual inspection systems utilize automated technologies to detect defects and inconsistencies across a wide range of products, from packaging to tablets, vials, and capsules. By automating the inspection process, machine visual inspection ensures that each product is meticulously checked for defects without slowing down production lines. These systems typically incorporate high-speed cameras, advanced lighting, and sophisticated image processing software to ensure reliable, fast, and accurate inspections, significantly improving the overall quality control process.

In this article, we will explore the performance and capabilities of automated visual inspection pharma, capsule vision inspection, and machine visual inspection systems. We will also highlight how these advanced inspection technologies help pharmaceutical manufacturers improve efficiency, reduce errors, and ensure that products meet rigorous safety and quality standards.

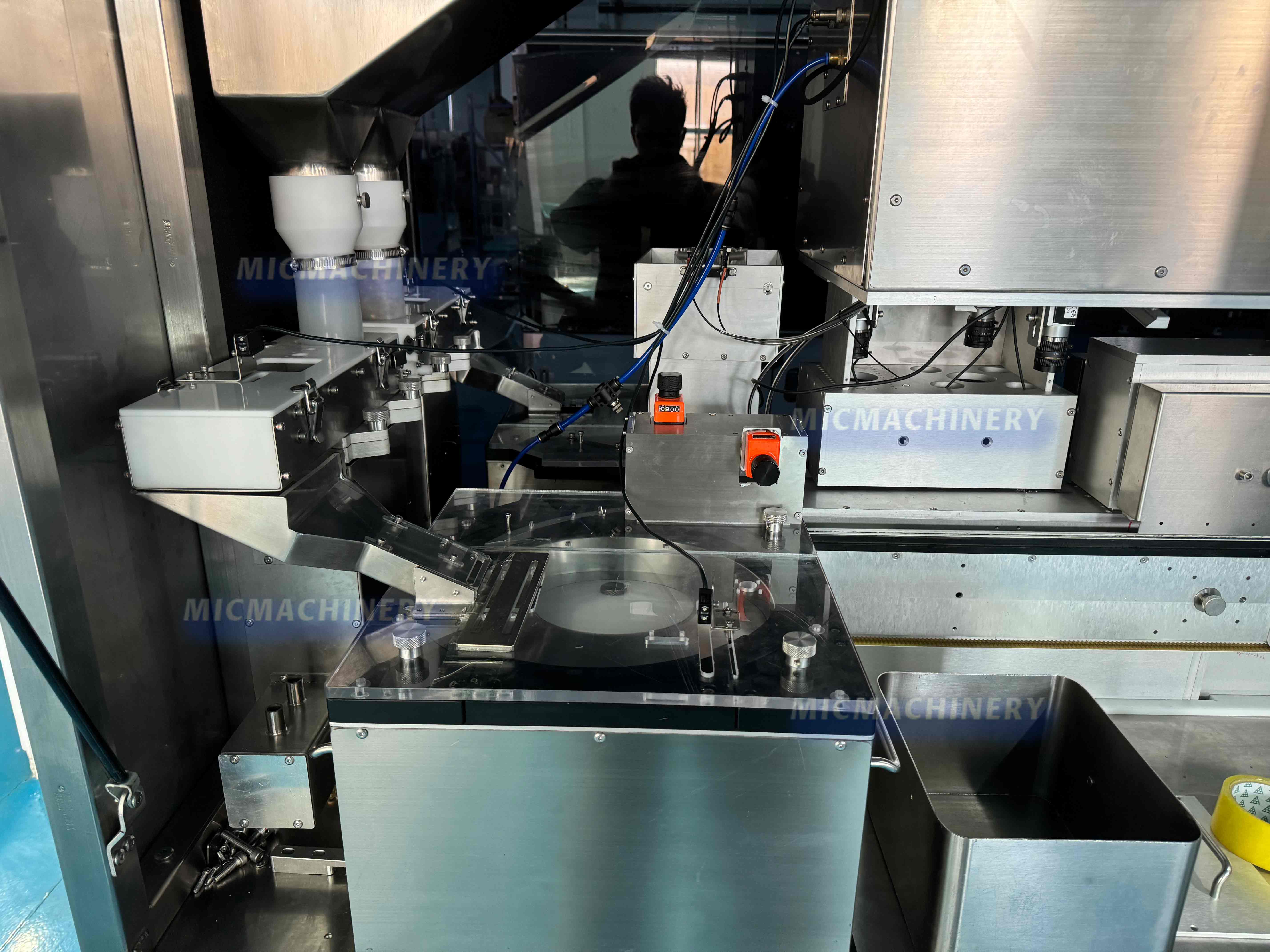

Sorting section

The sorting mechanism is composed of loading hopper, sorting fork, CAM, CAM motor and unloading mechanism.

Hopper in 316 SS , automatic lifting loading optional.

The stable CAM structure drives the sorting fork to reciprocating up and down, and Arrange the capsules in sequence on the unloading slide.

The ingenious unloading mechanism pushes the first capsule in the unloading chute down, and pushes a capsule position forward, while blocking the second capsule in the chute from falling, and the reciprocating movement realizes the capsule falling down and pushing down one by one.

The capsule unscrambling mechanism adopts vertical sorting mechanism similar to that sortingfork and shift fork of capsule filling machine.

Since most of the operators of pharmaceutical companies are very familiar with the similar unscrambling structure, there is no need for too much training in mechanical operation, and replacement and cleaning are also very simple.

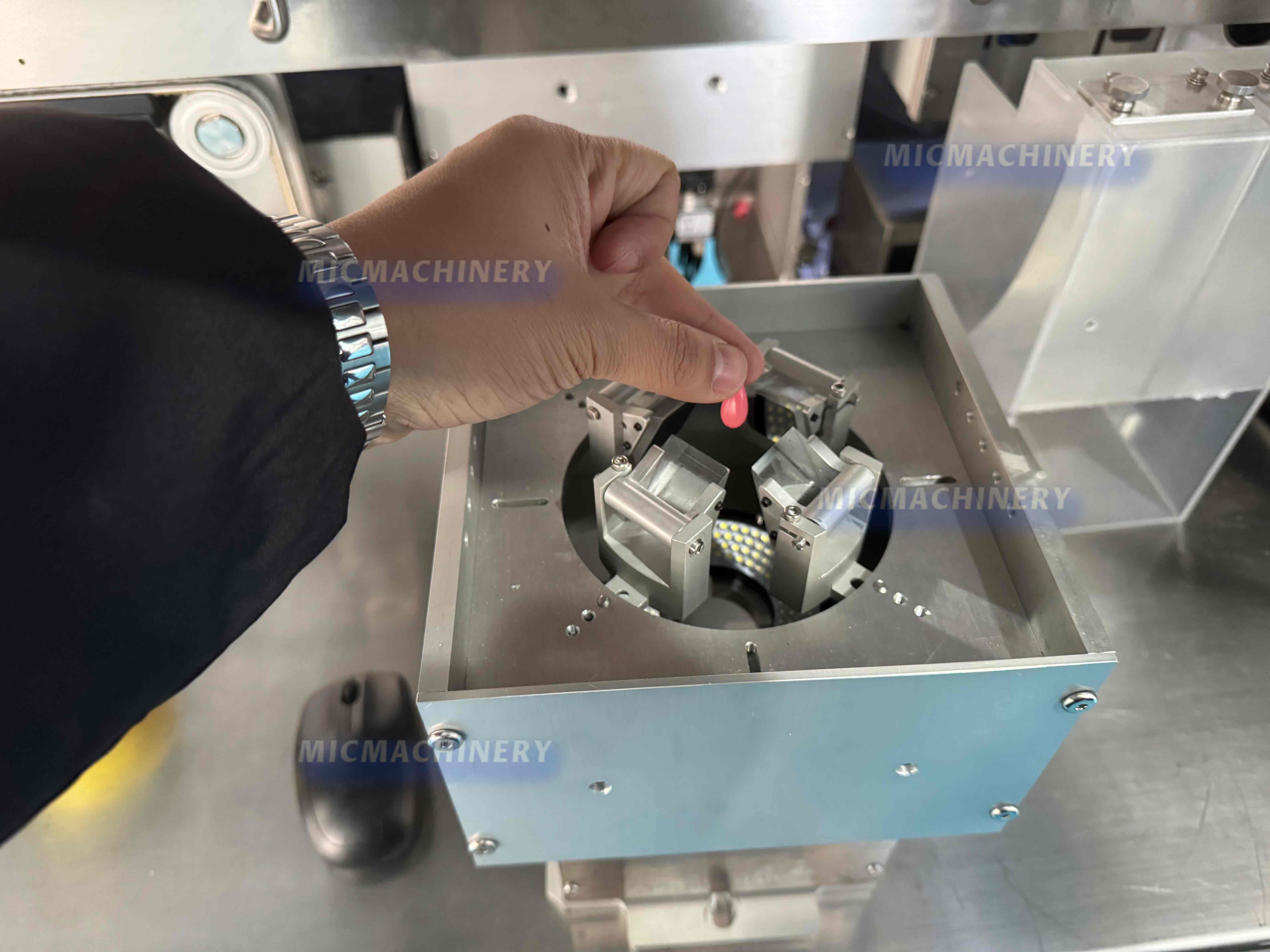

Capsule rotating mechanism

The stepper motor is used to drive CAM rotation and realize roller rotation. The capsule rotation is driven by the rotating friction of the roller.

Capsule pushing mechanism

Composed of sliding module driven by servo motor, front push bag plate, back push bag plate, push bag plate up and down action cylinder, front push bag plate back and forth action cylinder, etc. Its main function is to orderly transport the capsule toppled by the capsule organizing mechanism to the capsule to be checked, capsule detection and capsule exit position. Push-back capsule plate size can adapt to 00#, 0#, 0# lengthen, 1#, 2#, 3#, 4# and 5# commonly used capsules in pharmaceutical companies.

|

Channel |

30 chutes 、60 chutes |

|

Application |

00#-5# |

|

Defects |

Half top concave, defect, damage, foreign body, black spot, hair, different color, irregular , half section, fracture, deflated shell, split, split, broken, wrong insertion, abnormal length (long body, short body, long cap, short cap, long sac, short sac) stains, cracks/notches, dents, holes, missing printing, no printing, different specifications, double cap, empty capsule, etc. |

|

Inspection scope |

360°all round |

|

N.W |

400/800 |

|

Cameras |

Basler |

- MIC Automatic Tablet Capsule Vision Inspection Machine

- MIC Automatic BFS Visual Inspection Machine

- MIC Automatic Ampoule Machine Visual Inspection (Visual Inspection and High Voltage Leak Detection Combi Machine)

- MIC Rotary Automatic Visual Inspection Machine (400bpm)

- MIC Rotary Auto Visual Inspection Machine (600bpm)

- MIC Liner Automated Visual Inspection Equipment

- MIC Hard Capsule Vision Inspection Equipment (Hard Capsule & Softgel Gelatin)

- MIC Softgel Gelatin Automated Visual Inspection Pharma

- MIC Lyophilized Pharmaceutical Visual Inspection Machine

- MIC Oral Liquid Semi Automatic Visual Inspection Machine

- MIC Vial Washing Machine (Exterior Wall Cleaning And Drying Machine)

- MIC High Voltage Leak Detection (HVLD)