- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Application:

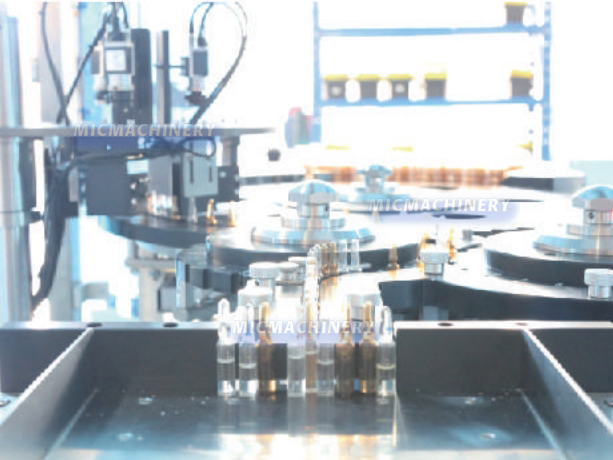

Mainly used for ampoule injection visible foreign bodies (including glass chips, fibers, hair, white pieces, white spots,etc.), liquid level and leakage (micro-holes, cracks)detection; it is also suitable for the detection of oral liquid and vial bottle water injection.

Working principle:

The machine adopts the principle of machine vision for the detection of visible foreign bodies. The tested product stops after high-speed rotation, and the industrial camera continuously takes pictures to obtain images. After computer system analysis, the tested product is judged whether it is qualified. The leakage detection is based onthe principle of high voltage discharge. And automatically separate qualified products and unqualified products.

In the pharmaceutical and packaging industries, the need for precise quality control is paramount, especially when dealing with sensitive products like ampoules. To meet this demand, machine visual inspection has become an essential tool for ensuring that each ampoule is free from defects, contamination, or damage. These advanced systems use high-resolution cameras and specialized sensors to perform real-time visual analysis of products, allowing for the rapid identification of issues such as cracks, particles, or other inconsistencies that could compromise product quality and safety.

One of the leading solutions in this field is the China ampoule visual inspection machine, a cutting-edge technology that has gained popularity for its accuracy and efficiency. Made with precision engineering, these machines are designed to handle the unique challenges of inspecting glass ampoules, such as detecting tiny fractures or air bubbles, which are critical for the integrity of pharmaceutical packaging. The China ampoule visual inspection machine leverages high-speed cameras, sophisticated image processing software, and artificial intelligence (AI) to detect even the most subtle defects, ensuring that only high-quality products are released into the market.

Additionally, the ampoule visual inspection machine is essential in pharmaceutical production lines where speed and precision are required. These machines are capable of inspecting hundreds or even thousands of ampoules per minute without compromising on inspection quality. By utilizing automated inspection processes, manufacturers can significantly reduce human error and increase production efficiency. The ampoule visual inspection machine ensures that each ampoule meets stringent regulatory standards and safety requirements, making it an invaluable asset in ensuring patient safety and maintaining brand reputation.

In this article, we will delve deeper into the performance of machine visual inspection, China ampoule visual inspection machine, and ampoule visual inspection machine, highlighting how these innovative systems are transforming quality control in the pharmaceutical industry.

1. The whole machine adopts full servo drive and a number of patented technology design, with complete independent intellectual property rights.

2. The detection of visible foreign bodies complies with Knapp rules accepted by European Pharmacopoeia and USFDA.

3. Leakage detection can detect ultra-fine holes and cracks that cannot be detected by tradi-tional methods.

4. The key parts using CNC precision machining. The main purchased parts are international famous brands, and the equipment runs stably and reliably.

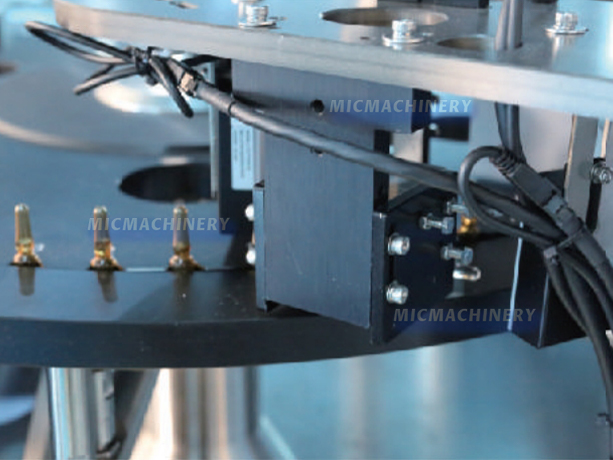

5. Rotary bottle servo system and detection device are set on the panel, effectively prevent the drug liquid and cleaning liquid to the equipment transmission and electrical damage, easy maintenance.

6. All specifications adopt fast loading and unloading mode, the large plate adopts servo automatic lifting, and there placement will be simple and fast.

7. The use of unequal distance screw into the bottle, can meet the single machine production, but also applicable to the front and back line of the linkage use.

8. The use of needle electrode, the use of tip discharge

principle, good detection effect.

9. To achieve a full range of products, full quantity of online testing.

10. Self-developed high frequency and high voltage power supply loaded on the product of low energy, short time, small current, will not cause secondary damage to the drug.

11. With fault alarm and fault display function. lt has the function of opening and stopping, ozone catalysis and electromagnetic protection.

12. All test data can be stored, uploaded and printed.

|

Aapplication |

1-20ml ampoule bottles |

|

Inspection |

Ampoule injection visible foreign bodies (including glass chips, fibers, hair, white pieces, white spots, etc.) |

|

Speed |

600 bottles/mins (based on 2ml); 500 bottles/mins (based on 10 ml) |

|

Resolution |

Light inspection zone≥40μm; leak testing zone ≥0.2-0.3um |

|

Power |

9KW (actual use 5KW) |

|

Power supply |

AC380V50Hz |

|

Weight |

5500KG |

|

Oversize |

5515*2020*2300mm(L*W*H)) |

|

Work table height |

950mm |

- MIC Automatic Tablet Capsule Vision Inspection Machine

- MIC Automatic BFS Visual Inspection Machine

- MIC Automatic Ampoule Machine Visual Inspection (Visual Inspection and High Voltage Leak Detection Combi Machine)

- MIC Rotary Automatic Visual Inspection Machine (400bpm)

- MIC Rotary Auto Visual Inspection Machine (600bpm)

- MIC Liner Automated Visual Inspection Equipment

- MIC Hard Capsule Vision Inspection Equipment (Hard Capsule & Softgel Gelatin)

- MIC Softgel Gelatin Automated Visual Inspection Pharma

- MIC Lyophilized Pharmaceutical Visual Inspection Machine

- MIC Oral Liquid Semi Automatic Visual Inspection Machine

- MIC Vial Washing Machine (Exterior Wall Cleaning And Drying Machine)

- MIC High Voltage Leak Detection (HVLD)