- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

BFS automatic visual inspection machine works for the comprehensive inspection (≥40μm foreign particles ) of pharmaceutical BFS packaging . The various kinds of unqualified products are distinguished through comparing the images taken.

Defects , which can affect the quality of the final product ,can be reliably detected during a gap-free inspection, which covers all surfaces of each individual container from the top to the bottom edge.

Technical advantages:

NO any damage to the packing, that is, non-destructive inspection.

All products are inspected, that is ,inspection online.

It has enough sensitivity to detect tiny black and white spots. (>40um foreign matters)

BFS light inspection machine is mainly for the characteristics of the row products,all-round detection, detection parts including head, tail, front and back. (2 groups ofworking stations, 6 cameras)

Can eliminate the interference of external factors or human factors.

Can be verified

In the fast-evolving world of manufacturing, ensuring product quality is paramount. Visual inspection machine are key players in maintaining high standards, providing manufacturers with a reliable and efficient way to identify defects and inconsistencies in products. These machines use high-resolution cameras, sensors, and sophisticated algorithms to visually analyze items in real time, detecting any discrepancies with precision.

The development of the auto visual inspection machine has significantly enhanced inspection capabilities. These machines are designed to operate automatically, reducing the need for manual intervention while increasing production speed. By integrating automated inspection processes, these machines can quickly detect defects such as cracks, chips, or misalignments in products, helping manufacturers minimize errors and waste. The auto visual inspection machine is particularly effective in industries where high throughput and consistent product quality are essential.

Another critical advancement in visual inspection technology is the automatic visual inspection machine principle, which relies on machine learning and AI-driven algorithms to continuously improve inspection accuracy. The principle behind these systems involves the use of cameras to capture detailed images of products as they move along the production line. The data is then processed and analyzed to detect any deviations from the desired specifications. With built-in adaptive learning capabilities, the machine can even identify new defects over time, making it a highly flexible and scalable solution for modern manufacturing environments.

In this article, we will explore the working principles and performance of visual inspection machine, auto visual inspection machine, and the automatic visual inspection machine principle, highlighting how these advanced systems are transforming quality control processes across industries.

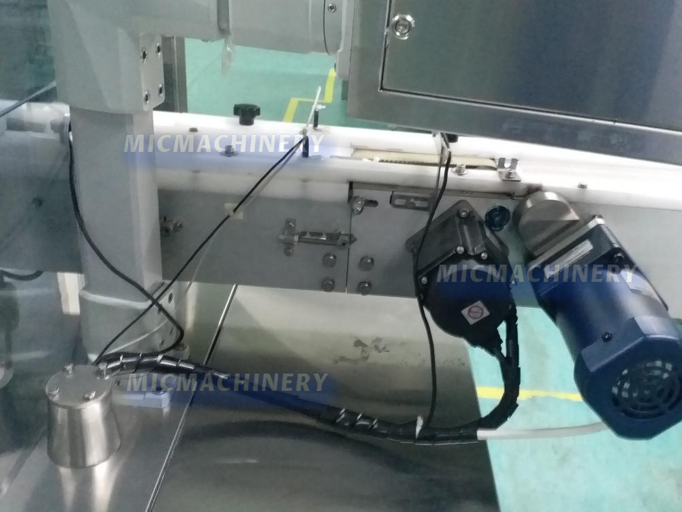

Feeding device

In the actual testing process of ampoule bottle, the liquid in the bottle head did notreturn when lying flat, so the current could not pass smoothly, which affected the testingeffect.

Before the bottle enters the high voltage discharge station, the side baffle is passed toensure that the posture of the bottle is horizontal when entering, so as to make theliquid medicine advection state and its better to ensure the detection effect.

The first inspection

The relative position relationship between the cameras and the products is shown in the figure

(In the first test, the cameras located on both sides and bottom).

The second inspection

The relative position relationship between the camera and the drug is shown in the figure

(The cameras is located on both sides and top).

|

Dimension |

3700*2500*2300mm |

|

Speed |

0~120rows/mins(3ml—10ml) |

|

Capacitance |

2kW(Includes high frequency and high voltage power supply)380V 50Hz |

|

High frequency |

600Hz |

|

High voltage |

0~22kV adjustable |

|

High frequency high voltage power supply |

200W |

|

Device |

Manufacturer and model |

|

Camera |

German Basler ACA1920-50GM |

|

Lens |

JP RICOH |

|

IPC |

Advantech |

|

PPC |

Advantech |

|

Light Source |

V-Light&LOTS |

|

Control system |

Omron |

|

Servo drive |

Omron |

- MIC Automatic Tablet Capsule Vision Inspection Machine

- MIC Automatic BFS Visual Inspection Machine

- MIC Automatic Ampoule Machine Visual Inspection (Visual Inspection and High Voltage Leak Detection Combi Machine)

- MIC Rotary Automatic Visual Inspection Machine (400bpm)

- MIC Rotary Auto Visual Inspection Machine (600bpm)

- MIC Liner Automated Visual Inspection Equipment

- MIC Hard Capsule Vision Inspection Equipment (Hard Capsule & Softgel Gelatin)

- MIC Softgel Gelatin Automated Visual Inspection Pharma

- MIC Lyophilized Pharmaceutical Visual Inspection Machine

- MIC Oral Liquid Semi Automatic Visual Inspection Machine

- MIC Vial Washing Machine (Exterior Wall Cleaning And Drying Machine)

- MIC High Voltage Leak Detection (HVLD)