- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Main features:

It uses star wheel Bernuli principle mechanism for the bottles in and out, and the broken bottle rate will be controlled extremely.

It has Shatter-proof device, when the bottles stuck in the front side, it will move back which will be sensed by the the proximity switch, and the machine stops running to prevent of breaking bottles.

Safe and reliable rejection system.

Parameter setting is simple, users can operate the machine after short time of training.

The detection electrode is placed on bottom, which is convenient for cleaning, and the items changes position from upright to lying flat while flat goes to upright with smooth process ,and the bottles will be not easily broken.

With communication interface, remote diagnosis can be realized.

The sensitivity of the detection can be adjusted according to customer requirements.

Continuously optimized software system, friendly operation interface.

Detection sensitivity and parameters can be easily set to meet user needs.

Reserved communication interface, remote monitoring, which can support the technical services online.

The unqualified images can be saved, and the unqualified images can be read online to facilitate user statistics and process adjustment.

High voltage leak detection is crucial in industries where electrical systems operate at high voltages, such as power stations, transformers, and cables. Detecting leaks early is vital to prevent system failures, reduce downtime, and ensure safety. Small leaks in high voltage equipment can escalate into significant problems if not identified promptly, making high voltage leak detection an essential process for maintaining system reliability and efficiency.

The Role of High Voltage Leak Detection Equipment

High voltage leak detection equipment is designed to identify leaks or faults in electrical systems before they cause major failures. Using advanced technologies such as partial discharge (PD) detection, infrared thermography, and acoustic sensors, this equipment can monitor for signs of degradation or electrical leakage that could compromise the integrity of high voltage systems.

The primary function of high voltage leak detection equipment is to provide real-time monitoring, offering quick identification of any issues. With the ability to detect even minor faults, these systems can prevent costly breakdowns and improve safety by ensuring that leaks are addressed before they lead to catastrophic failures.

Performance of High Voltage Leak Detection Systems

The performance of high voltage leak detection systems is characterized by their precision and responsiveness. These systems continuously monitor for any anomalies, with sensors that detect even the smallest leaks. The effectiveness of high voltage leak detection equipment is enhanced by real-time data analysis, which enables rapid response and minimizes operational disruptions. In some cases, these systems are integrated with predictive analytics, allowing for proactive maintenance and extended equipment lifespan.

Conclusion

High voltage leak detection is a critical aspect of maintaining the safety and efficiency of high-voltage electrical systems. By using reliable high voltage leak detection equipment, industries can prevent failures, ensure operational stability, and reduce the risk of costly downtime. Investing in effective high voltage leak detection equipment is essential for improving the overall performance and longevity of high-voltage infrastructure.

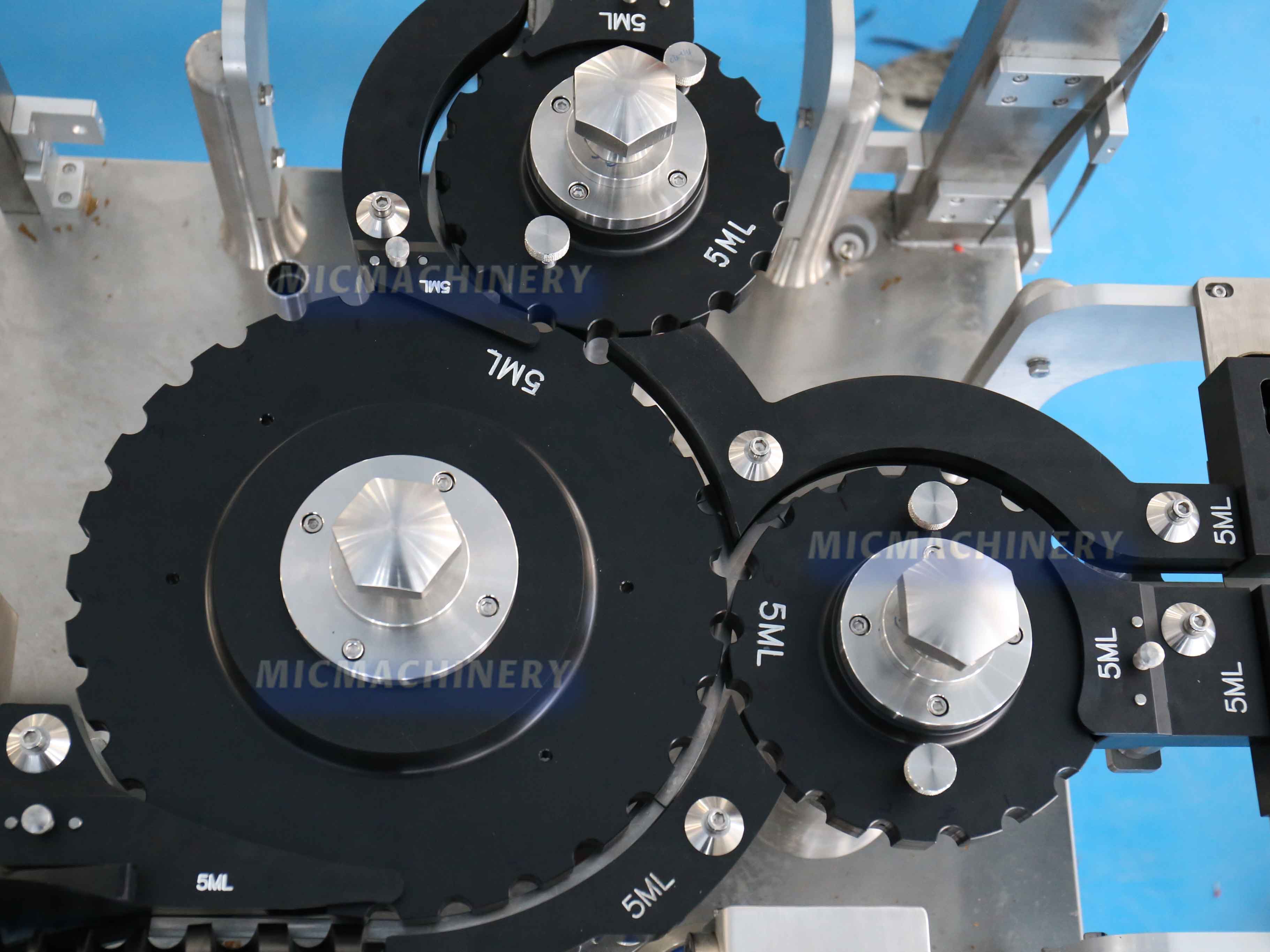

High voltage discharge work station

High-voltage discharge station: 4-station

Each detection station can be flexibly set according to specific requirements.

Detection position with clear scale markings, be in accurate.

Safe and reliable rejection method

It has great advantages over the previous vacuum suction cups and vacuum adsorption methods (No such situation will occur,such as, the air leaks due to wear of the suction cup, or the airway is blocked due to liquid leakage).

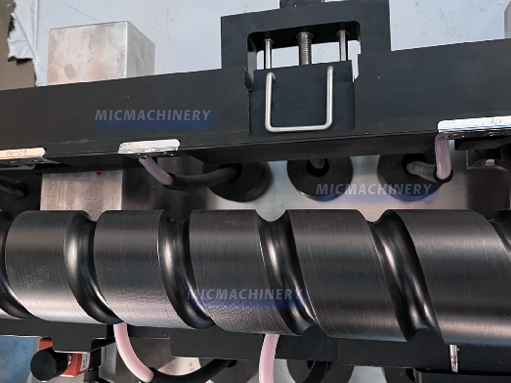

Bottle unscrambling mechanism

The bottle unscrambling mechanism can better ensure the state of the bottle when changing its posture.

| Application |

1-20ml ampoule bottles, oral liquid bottles, vials |

| Inspection item |

Cracks, micropores and other defects caused by liquid leakage |

| Speed |

600 botttls/min (based on 2ml) |

| Resolution |

>0.1μm |

| Power | 3KW |

| Voltage |

AC 380V 50Hz |

| Net weight | 1500KG |

- MIC Automatic Tablet Capsule Vision Inspection Machine

- MIC Automatic BFS Visual Inspection Machine

- MIC Automatic Ampoule Machine Visual Inspection (Visual Inspection and High Voltage Leak Detection Combi Machine)

- MIC Rotary Automatic Visual Inspection Machine (400bpm)

- MIC Rotary Auto Visual Inspection Machine (600bpm)

- MIC Liner Automated Visual Inspection Equipment

- MIC Hard Capsule Vision Inspection Equipment (Hard Capsule & Softgel Gelatin)

- MIC Softgel Gelatin Automated Visual Inspection Pharma

- MIC Lyophilized Pharmaceutical Visual Inspection Machine

- MIC Oral Liquid Semi Automatic Visual Inspection Machine

- MIC Vial Washing Machine (Exterior Wall Cleaning And Drying Machine)

- MIC High Voltage Leak Detection (HVLD)