- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the pharmaceutical industry, ensuring product integrity and safety is crucial, and one of the most effective ways to achieve this is through the use of pharmaceutical visual inspection machines. These advanced machines employ high-resolution cameras, automated software, and specialized imaging technology to inspect pharmaceutical products for defects such as cracks, chips, contamination, or mislabeling. The primary advantage of pharmaceutical visual inspection machines lies in their ability to perform fast, accurate, and reliable inspections at high speeds, ensuring that each product meets stringent quality standards. By automating the inspection process, these machines reduce human error, increase throughput, and enhance overall efficiency in the production line.

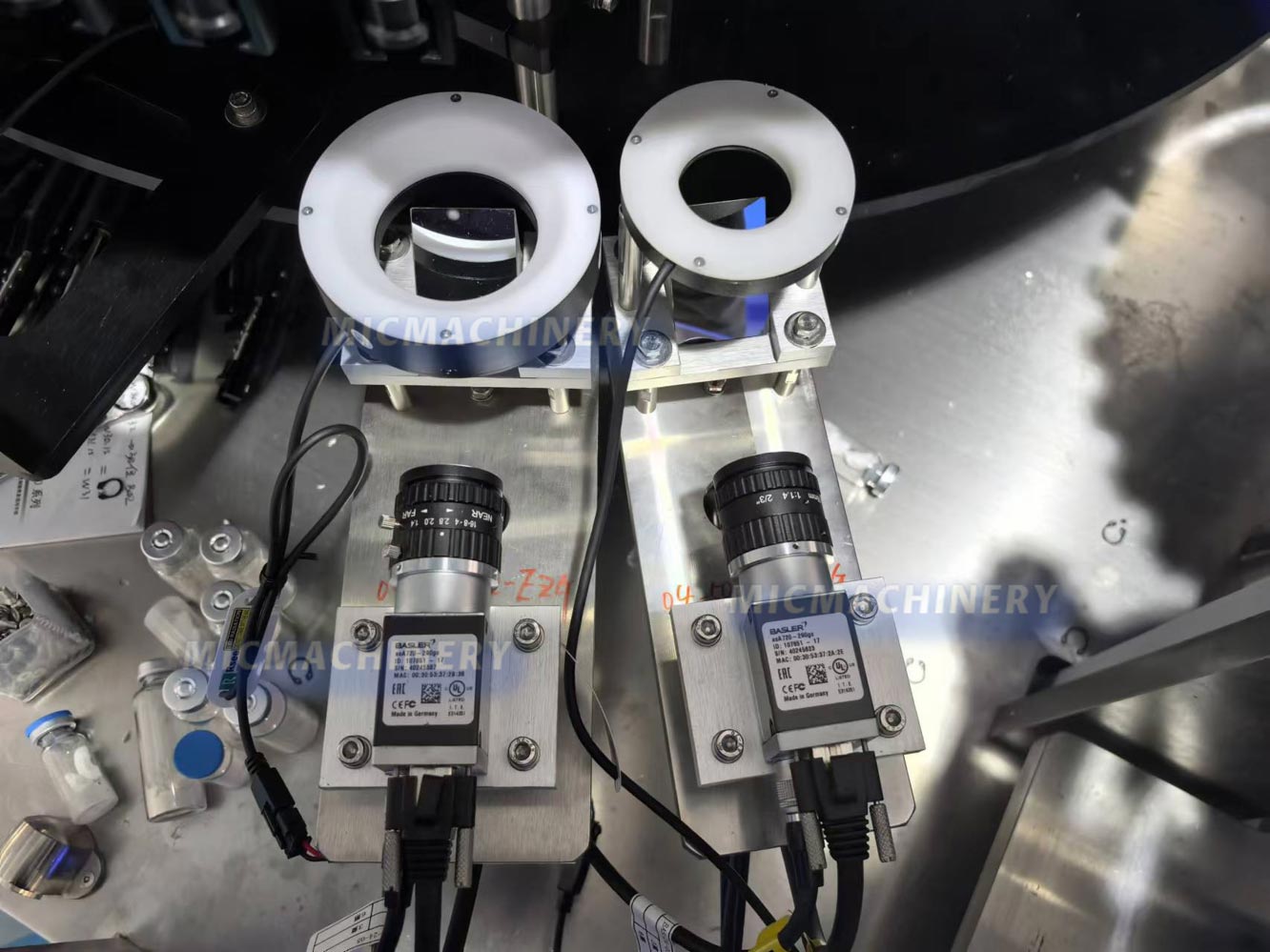

A key application of pharmaceutical visual inspection machines is in the inspection of vials, which are commonly used to package injectable drugs and other sensitive pharmaceutical products. The automatic vial inspection machine is designed to inspect vials for a range of potential defects. These include cracks, chips, discoloration, particulate contamination, or issues with vial labeling. With the ability to process vials at high speeds, the automatic vial inspection machine ensures that only defect-free vials are released into the market, minimizing the risk of product recalls and ensuring patient safety. These machines are equipped with advanced sensors and cameras that provide detailed visual inspections, ensuring that every vial is inspected with precision and accuracy.

Beyond vials, inspection machines in the pharmaceutical industry play a broader role in ensuring that all pharmaceutical products, from tablets to bottles and packaging, meet the highest quality standards. Inspection machines in the pharmaceutical industry are designed to automate the quality control process, providing a fast, reliable method for detecting defects, verifying product specifications, and ensuring compliance with regulatory requirements. Whether inspecting tablet coatings, packaging integrity, or vial sterility, these systems ensure that products are consistently safe for consumption and distribution.

In this article, we will explore the performance of pharmaceutical visual inspection machines, the advantages of automatic vial inspection machines, and the broader role of inspection machines in the pharmaceutical industry. We will also discuss the latest advancements in these technologies and how they help manufacturers improve efficiency, reduce errors, and ensure compliance with industry standards, ultimately enhancing the safety and quality of pharmaceutical products.

Bottle feeding

Top inspection

Bottom inspection

Rotary system

Powder top inspection

|

Oversize(L*W*H) |

1840*2500*2200(unclude the size of the inlet/outlet carrier belt, which can be customzied to work in line with other machines) |

|

Net weight |

≈3000Kg |

|

Application |

Tube vials/molded bottles up to 30ml |

|

Design speed |

600p/min |

|

Inspection principle |

Machine vision non-contact inspection |

|

Inspection function |

(1) Powder defects: visible foreign matter on the surface, such as glass,hair & fiber, black spots, etc.; fragmented, product discoloration, liquefied state; (2) Bottle cap defects: no plastic cap or aluminum cap, damaged,deformed, dirt, scratches, dents, missing rubber plug, free position, etc.; (3) Aethetics: cracks, scratches, breakage, bubble points, and contaminants inside and outside of the container, etc.; (4) Empty. (5) Leakage defects: unqualified sealing, air in the bottle. |

|

Power |

<12KW |

|

Rejection |

Bernoulli pneumatic rejection |

|

Compressed air |

0.3-0.5MPa |

|

Main material |

304 SS (06Cr18Ni10) , POM((CH2O)n), etc |

|

Operating temperature & humidity |

T * 0~35℃, H *15%~80% |

- MIC Automatic Tablet Capsule Vision Inspection Machine

- MIC Automatic BFS Visual Inspection Machine

- MIC Automatic Ampoule Machine Visual Inspection (Visual Inspection and High Voltage Leak Detection Combi Machine)

- MIC Rotary Automatic Visual Inspection Machine (400bpm)

- MIC Rotary Auto Visual Inspection Machine (600bpm)

- MIC Liner Automated Visual Inspection Equipment

- MIC Hard Capsule Vision Inspection Equipment (Hard Capsule & Softgel Gelatin)

- MIC Softgel Gelatin Automated Visual Inspection Pharma

- MIC Lyophilized Pharmaceutical Visual Inspection Machine

- MIC Oral Liquid Semi Automatic Visual Inspection Machine

- MIC Vial Washing Machine (Exterior Wall Cleaning And Drying Machine)

- MIC High Voltage Leak Detection (HVLD)